An environmentally friendly spray booth

A paint spray booth, environmentally friendly technology, applied in the direction of spray devices, etc., can solve the problem of reducing the air flow area, and achieve the effect of reducing the flow area and increasing the friction force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

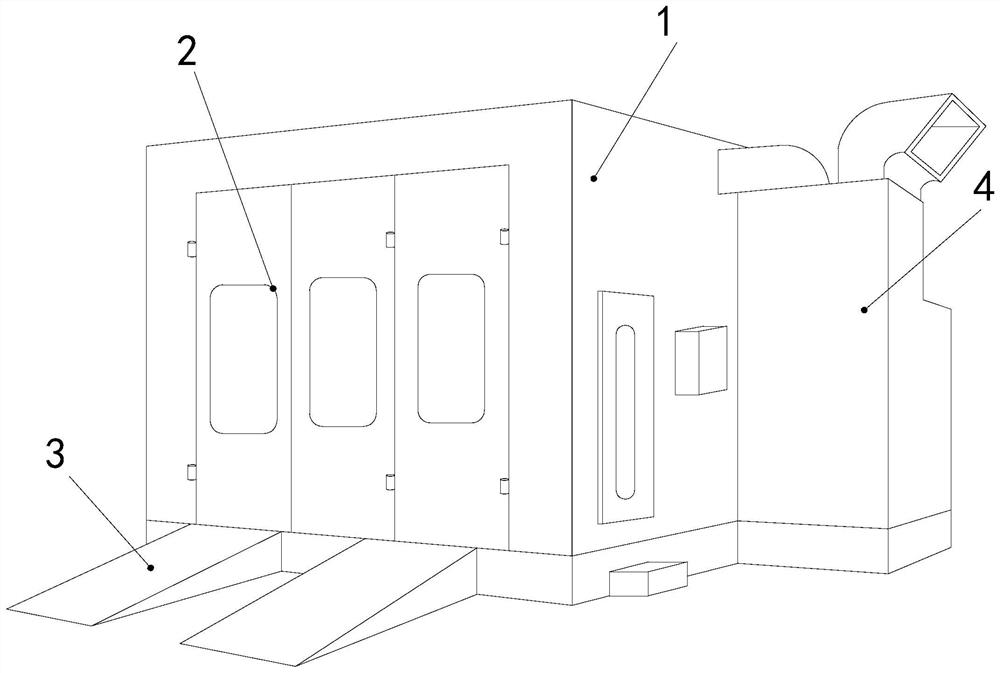

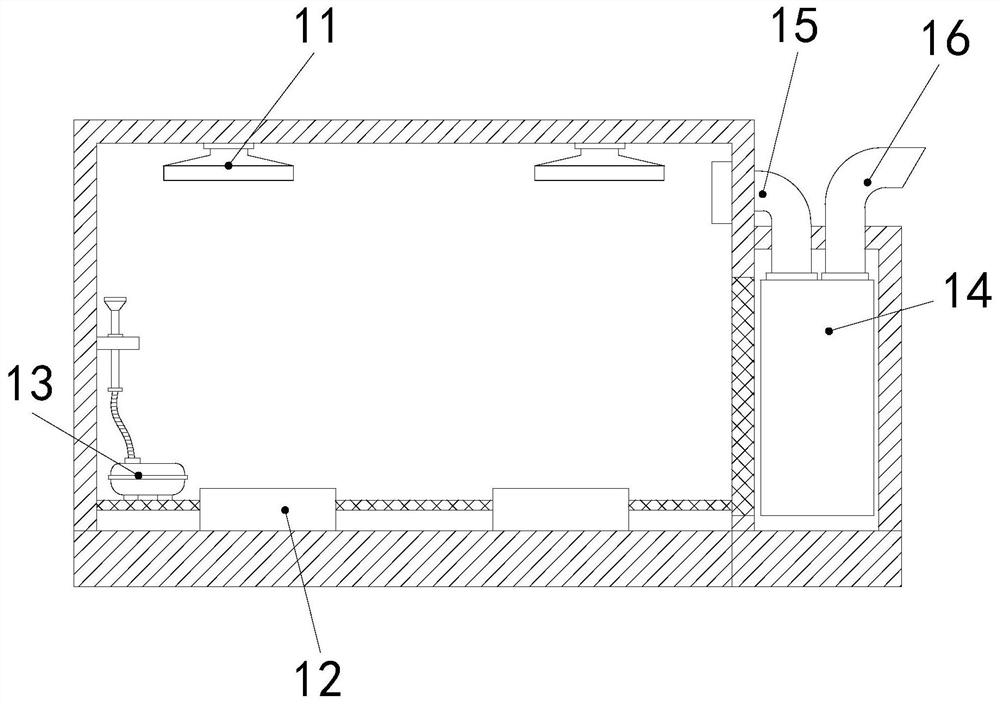

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

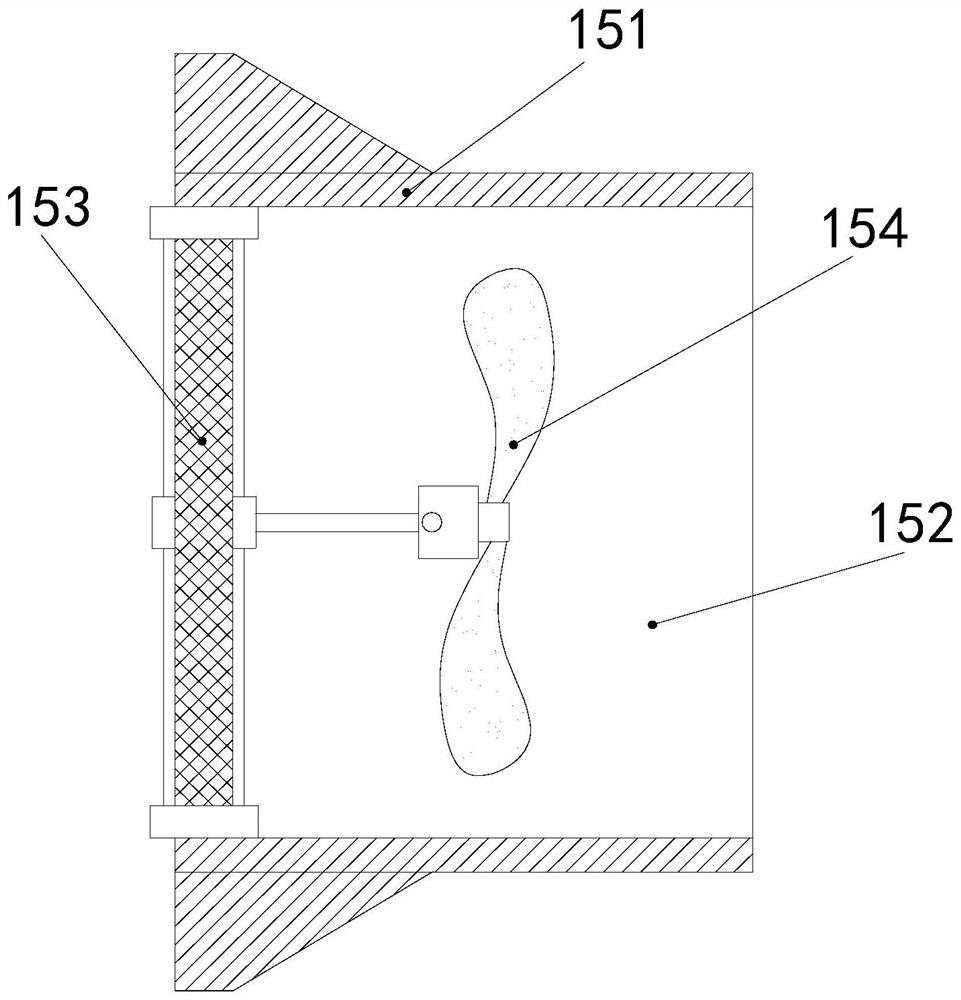

[0027] Its structure includes a room body 1, a door 2, a support frame 3, and an air purification block 4. The front end of the room body 1 is provided with a door 2, and there are two support frames 3 arranged horizontally on the door 2. The front end of the air purification block 4 is installed at the side end of the room body 1, and the room body 1 includes an illumination lamp 11, a support block 12, a dust suction block 13, a purification block 14, an air suction pipe 15, and an exhaust pipe 16. There are two illuminating lamps 11 installed on the top of the room body 1, two supporting blocks 12 are installed at both ends of the bottom of the room body 1, and the dust suction block 13 is arranged on the top of the room body. The inner side end of the body 1, the purification block 14 is embedded in the side end of the room body 1, one end of the exha...

Embodiment 2

[0032] Example 2: Please refer to Figure 6-Figure 8 The specific embodiment of the present invention is as follows: the scraping block a3 includes a rotating shaft a31, a scraping body a32, a connecting rod a33, and a connecting block a34, and eight scraping bodies a32 are arranged at the side end of the rotating shaft a31, and four It is a group embedded in the side end of the rotating shaft a31, the connecting rod a33 is embedded in the rear end of the rotating shaft a31, the connecting block a34 is embedded in the rear end of the connecting rod a33, and is connected with the fan 154. The distance between the two sets of scraping bodies a32 at the side end of the rotating shaft a31 and the horizontal plane is greater than the width between the filter screens a2, which is beneficial for the scraping body a32 to rotate through the rotating shaft a31 and scrape off the paint powder attached to the filter screen a2 .

[0033] The scraping body a32 includes a base b1, a fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com