Drying apparatus and method

A kind of drying equipment and drying technology, which is applied in the field of metal beverage container drying equipment and metal beverage container drying, and can solve the problems of can metal damage, raising the temperature of the dryer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

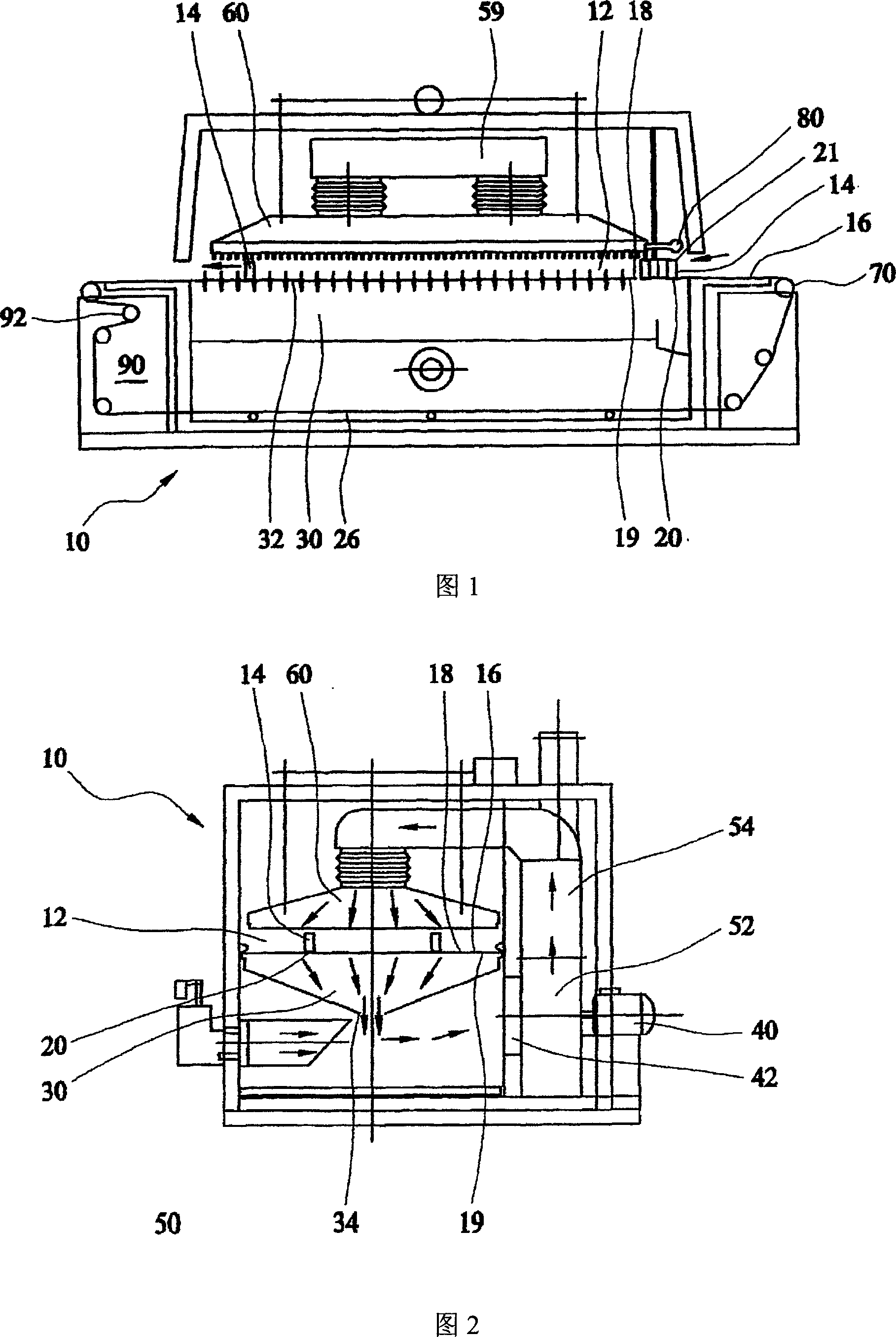

[0039] As shown in FIGS. 1 and 2 , the present invention provides a drying device 10 including a drying chamber 12 . In use, containers, in particular metal beverage containers, preferably cans 14 for drinking, are arranged to pass through the drying device 10 . As mentioned above, the drying equipment 10 is used in the line can making equipment and method, and is arranged after or downstream of the cleaning equipment. Thus, the drying apparatus is used to remove water, chemicals, contaminants and other substances from the tank 14 prior to further processing of the tank 14, such as printing the outside of the tank 14 and coating the inside of the tank 14. moisture.

[0040] The tanks 14 are supported on support means in the form of conveyor belts 16 . The conveyor belt 16 comprises a Kevlar open mesh type belt. Accordingly, the conveyor belt 16 has a plurality (or, more specifically, a large number) of fluid passages through the conveyor belt.

[0041] The cans 14 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com