Method for exhaust gas purification

A technology for waste gas purification and waste gas, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation. Uniform, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

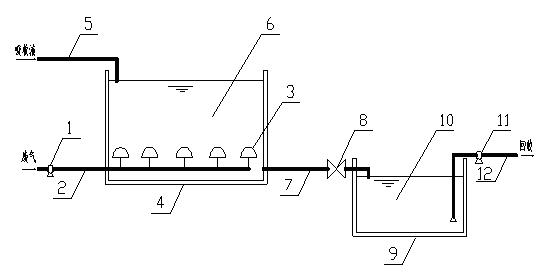

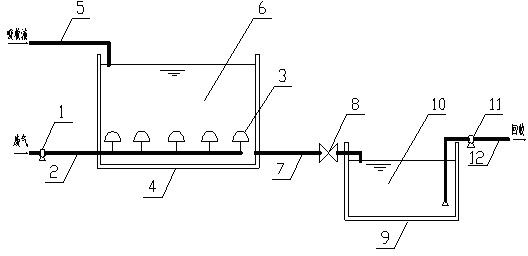

[0022] A new type of exhaust gas purification method has the following steps in sequence:

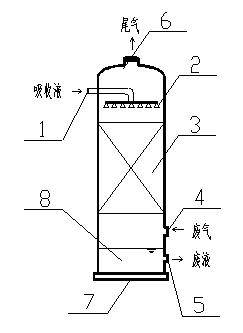

[0023] 1) The carbon dioxide waste gas is transported from the fan 1 through the waste gas pipe 2 to the diffusion plate microporous aeration device 3 at the bottom of the absorption tank 4, and enters the absorption tank 4 after being fully diffused;

[0024] 2) The absorption tank 4 is filled with monoethanolamine absorbing liquid matched with carbon dioxide waste gas, the concentration of which is 10%-30%, and the carbon dioxide waste gas passes through the microporous aeration head 3 of the diffusion plate microporous aeration device to form tiny bubbles into the monoethanolamine The absorption liquid 6, the carbon dioxide waste gas diffuses step by step from the bottom of the monoethanolamine absorption liquid 6 to the upper part, and is fully absorbed in the relatively static monoethanolamine absorption liquid 6. The monoethanolamine absorption solution 6 is placed in the absorption ta...

Embodiment 2

[0027] A new type of exhaust gas purification method has the following steps in sequence:

[0028] 1) The sulfur dioxide waste gas is transported from the fan 1 through the waste gas pipe 2 to the diffusion tube microporous aeration device 3 provided at the bottom of the absorption tank 4, and enters the absorption tank 4 after being fully diffused;

[0029] 2) The absorption tank 4 is filled with lime water absorption liquid that matches the sulfur dioxide waste gas, and its concentration is 5%-15%. The sulfur dioxide waste gas passes through the diffuser tube, microporous aeration device, and the microporous aeration head 3 to form tiny bubbles into the lime water. The absorption liquid 6, the sulfur dioxide waste gas diffuses step by step from the bottom of the lime water absorption liquid 6 to the upper part, and is fully absorbed in the relatively static lime water absorption liquid 6. The lime water absorption liquid 6 is placed in the absorption tank 4. After the sulfur diox...

Embodiment 3

[0032] A new type of exhaust gas purification method has the following steps in sequence:

[0033] 1) The ammonia waste gas is transported from the fan 1 through the waste gas pipe 2 to the membrane-type microporous gas diffuser 3 at the bottom of the absorption tank 4, and enters the absorption tank 4 after being fully diffused;

[0034] 2) The absorption tank 4 is filled with sulfuric acid absorption liquid matched with the ammonia waste gas, the concentration of which is 20%-30%. The ammonia waste gas passes through the membrane type microporous gas diffuser microporous aeration head 3 and then forms tiny bubbles into it Sulfuric acid absorption liquid 6, the ammonia waste gas diffuses step by step from the bottom of the sulfuric acid absorption liquid 6 to the upper part, and is fully absorbed in the relatively static sulfuric acid absorption liquid 6. The sulfuric acid absorption liquid 6 is placed in the absorption tank 4, and the ammonia waste gas is absorbed After the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com