A kind of aqueous sodium ion battery

A sodium-ion battery, water-based technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor electrochemical stability, high solubility, and easy decomposition of water-based sodium-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

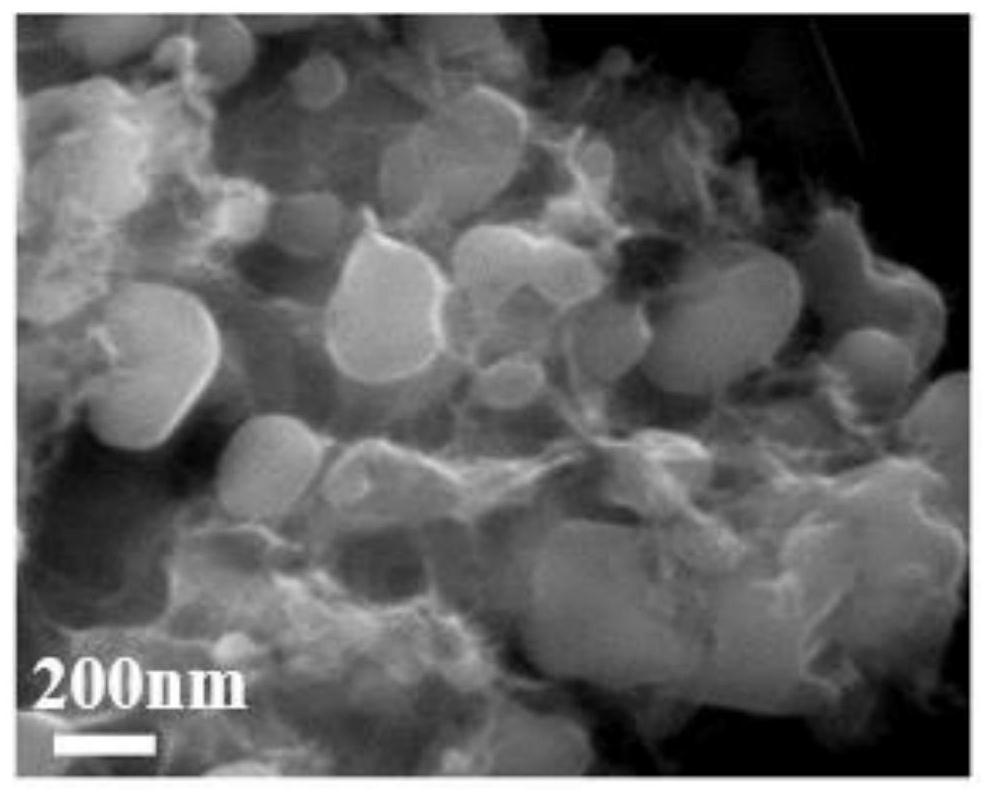

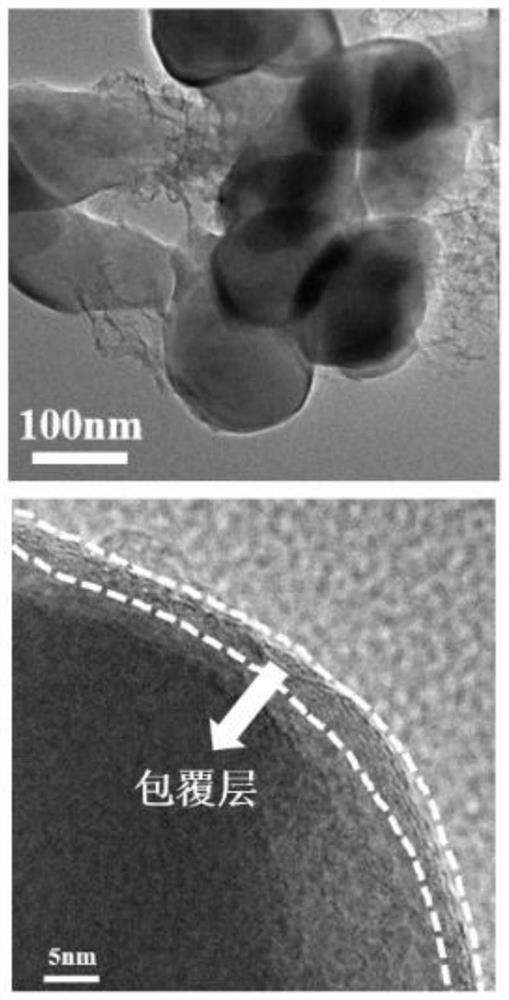

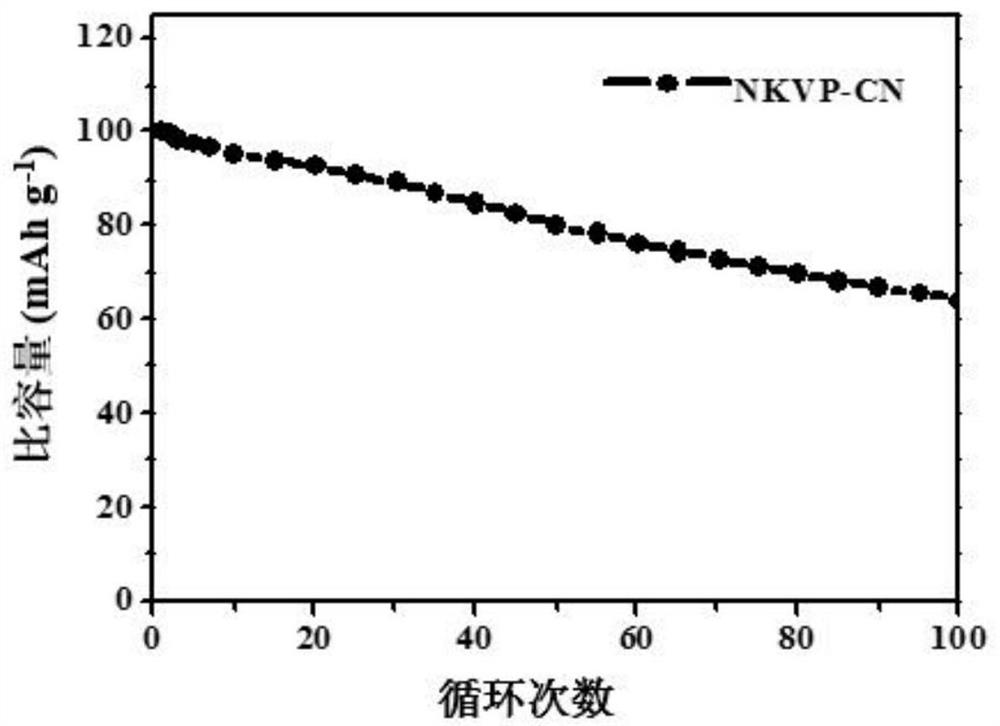

[0036] In the present invention, the positive electrode active material for the positive electrode of the aqueous sodium ion battery comprises potassium ion doped sodium vanadium phosphate particles and a carbon layer and a carbon nitrogen layer coated on the surface of the potassium ion doped sodium vanadium phosphate particles in sequence, Wherein, the particle size of the potassium ion-doped sodium vanadium phosphate particles is preferably 200-300 nm, and the total thickness of the carbon layer and the carbon-nitrogen layer is preferably 4-6 nm. In the present invention, the preparation method of the positive electrode active material preferably comprises the following steps:

[0037] Water, citric acid, NH 4 VO 3 , NH 4 h 2 PO 4 , NaOH, KOH and N,N-dimethylamide are mixed, and after removing the solvent in the obtained mixed material, the first carbonization treatment is carried out in a protective atmosphere to obtain potassium ion-doped sodium vanadium phosphate par...

Embodiment 1

[0054] Preparation of positive electrode active material: 15mL deionized water, 1mmol citric acid, 2mmol NH 4 VO 3 and 3 mmol of NH 4 h 2 PO 4Mix and stir for 0.5h, add 2.85mmol of NaOH and 0.15mmol of KOH, continue to stir for 10min, add 50mL of DMF, continue to stir for 3h in a water bath at 80°C, then put the residue in an oven and dry at 70°C for 12h ; The resulting dried material is ground and put into a tube furnace under Ar-H 2 Mixed atmosphere (H 2 The volume fraction is 5%), heat preservation treatment at 400°C for 4h, then raise the temperature to 750°C at a rate of 5°C / min, and heat preservation treatment at 750°C for 8h, to obtain potassium ion-doped carbon layer coating Sodium vanadium phosphate, denoted as NKVP-C;

[0055] The NKVP-C was mixed with 75 mL of trimethylolmethane buffer solution with a concentration of 0.5 mol / L, ultrasonicated for 30 min, and then hydrochloric acid with a concentration of 1 mol / L was added dropwise under stirring conditions to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com