Red mud superconducting high-gradient magnetic separator

A high-gradient magnetic separation and separator technology, applied in high-gradient magnetic separators and other directions, can solve the problems of low magnetic separation efficiency and achieve the effect of improving work efficiency and high recovery value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

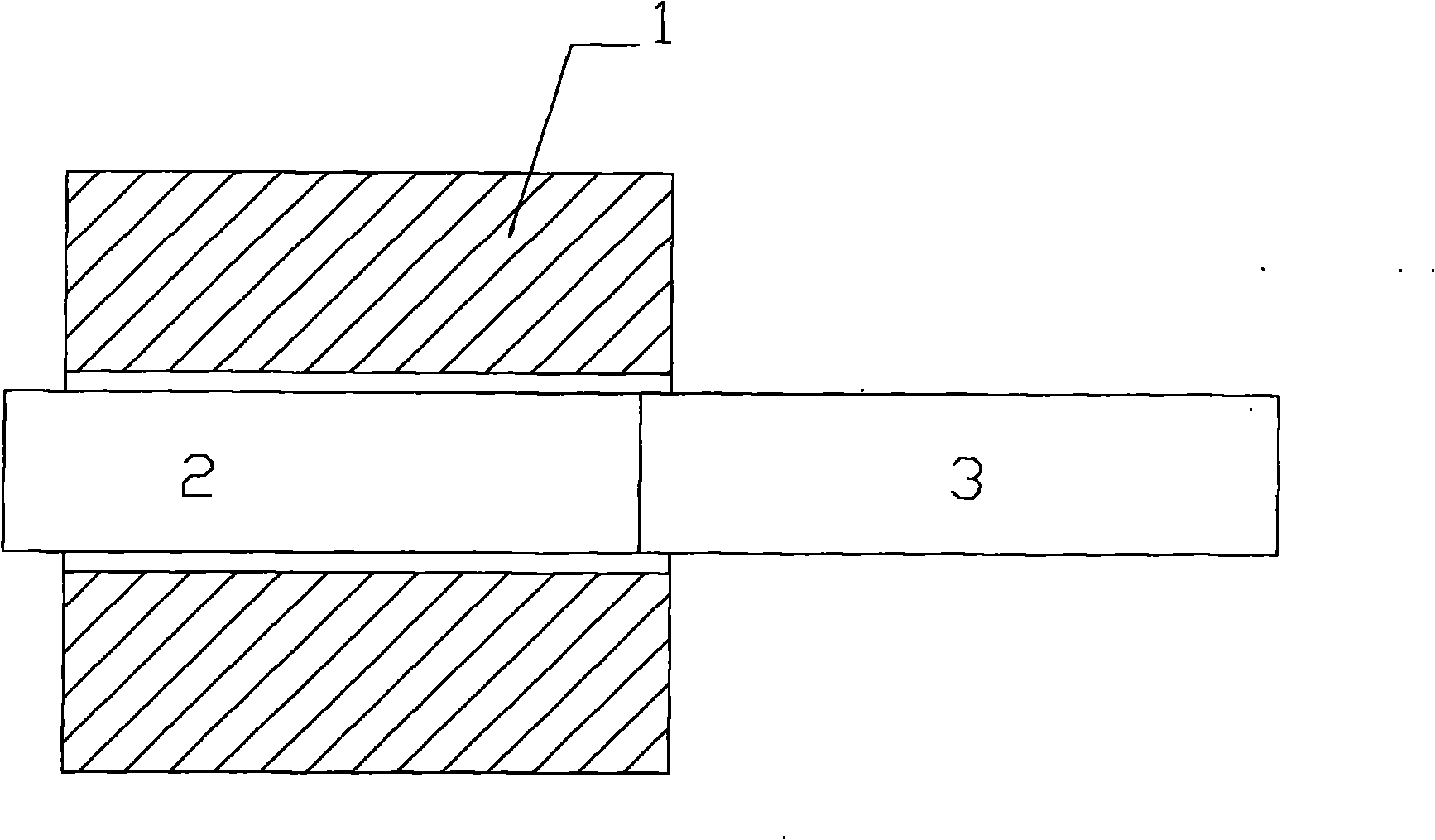

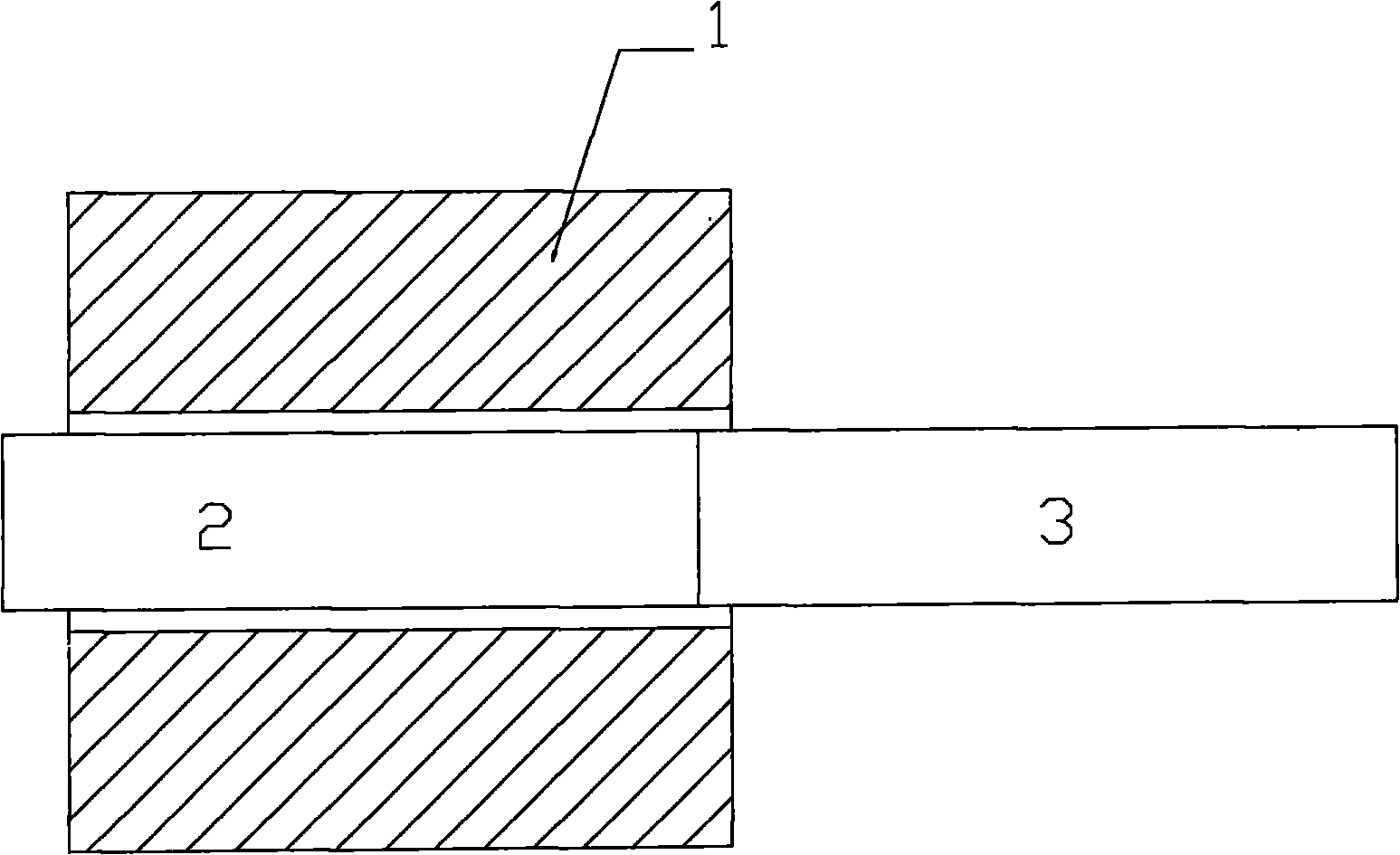

Image

Examples

example 1

[0032] Using the red mud superconducting high-gradient magnetic separator of the present invention, stainless steel wool is used as a polymagnet, and under the operating condition of a background magnetic field strength of 4 Tesla, the ferromagnetic particles in the red mud of Shandong Aluminum Industry are separated, and the red mud after separation The iron content in the medium is less than 5%, and the iron content of the separated ferromagnetic particles can reach more than 40%. And the operating cost is only equivalent to 20% of electromagnetic separation. The recovery rate is high, the energy consumption is low, and it has great economic benefits.

example 2

[0034] Kaolin has been widely used as an additive in the paper industry. Since kaolin contains about 0.8% iron, the paper will turn yellow when stored for a long time. How to remove iron from kaolin? It has been the subject of research by kaolin manufacturers.

[0035] Get the high-quality kaolin produced in Beihai, Guangxi, the iron content is 0.8%, adopt the red mud superconducting high gradient magnetic separator of the present invention, and wherein the steel wool density is doubled, under the background magnetic field strength of 5 Tesla, the Iron is adsorbed and its iron content is reduced to 0.5%. The whiteness of kaolin is increased by more than 2 degrees, and the product grade is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com