Moisture recycling supersonic speed gas-purification separation device

A gas purification and separation device technology, which is applied in separation methods, dispersed particle separation, and production of fluids, etc., can solve the problems of high equipment investment and operating costs, low maturity level, environmental pollution, etc., so as to improve separation efficiency and environmental protection benefits. , high air velocity, flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

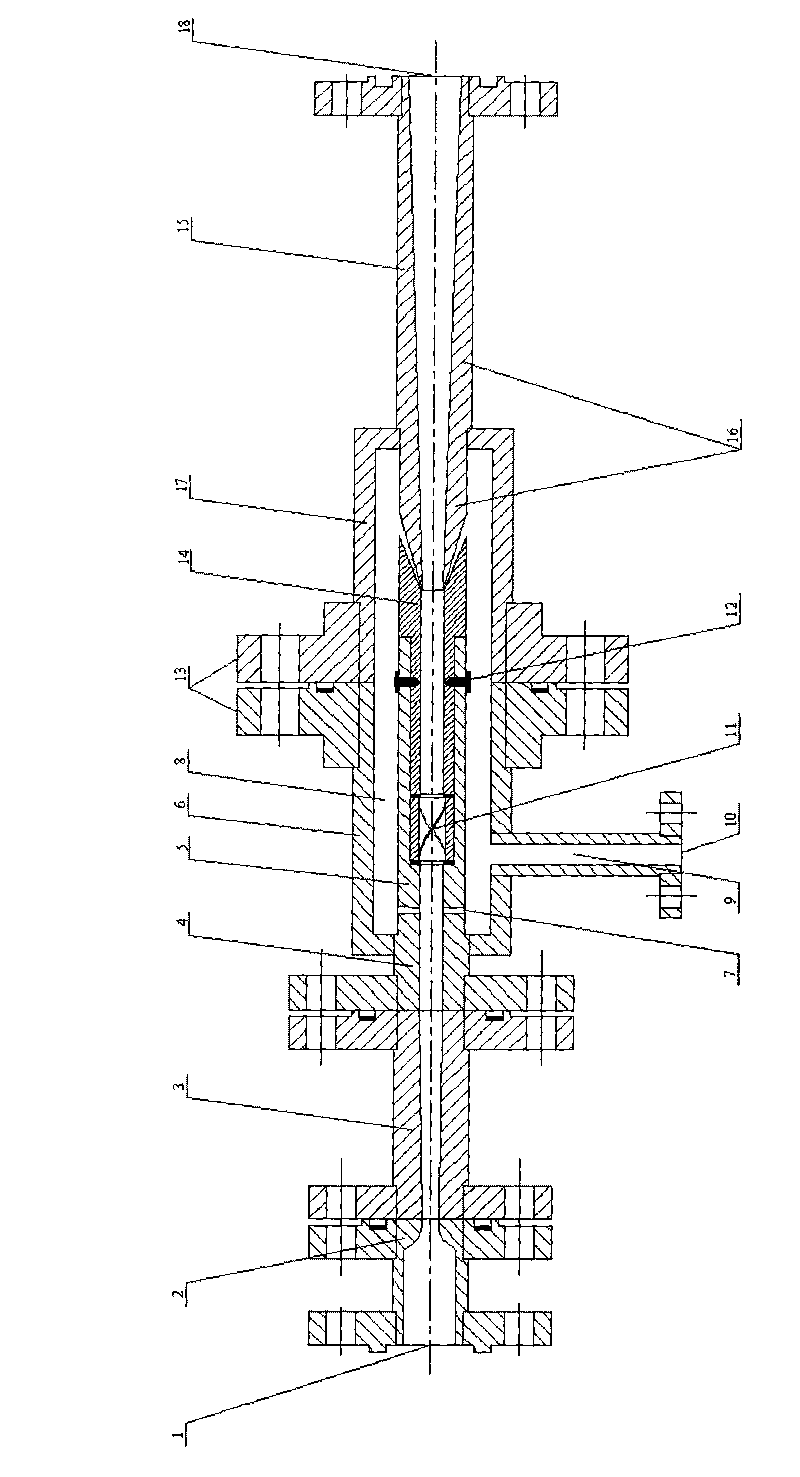

[0039] see Figure 1 to Figure 10 The technical scheme of the present invention is implemented by conventional processing techniques.

[0040] Technical scheme of the present invention sees Figure 1-10 , the device of the present invention is provided with moisture recirculation purification and separation components,

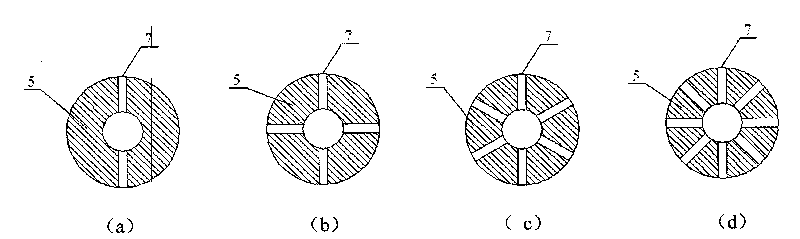

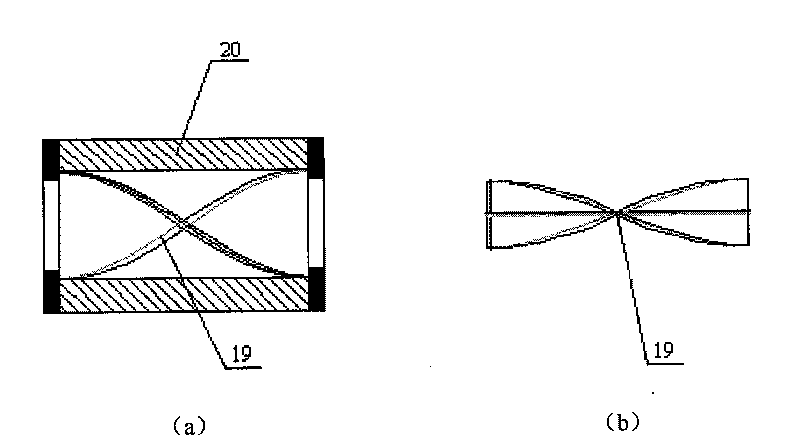

[0041]The device of the present invention mainly includes a Laval nozzle tapering section 2, a Laval nozzle expanding section 3, a straight pipe section 4, a recirculation port 7, a recirculation separation chamber 8, a cyclone 11, and a hydrocyclone fixed Main parts such as sleeve 14 and diffuser pipe 15 are formed. Between the gas source supply pipe and the wet gas inlet 1, between the tapering section 2 of the Laval nozzle and the expanding section 3 of the Laval nozzle, between the expanding section 3 and the straight section 4 of the Laval nozzle, The straight pipe section 4 and the diffuser pipe 15 are sequentially connected by flanges. Wherein: ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com