Composite liquid chromium removal agent as well as preparation method and application thereof

A composite, liquid technology, applied in the field of chromium removal agent, can solve the problems of single reducing agent, inability to meet the requirements of chromium removal, and poor treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A composite liquid chromium remover, comprising the following raw materials in mass percentages:

[0032] 22% of ferrous sulfate heptahydrate, 15% of antimony oxychloride, 48% of water, 7% of absolute ethanol, 8% of methyl cellulose, and the viscosity of methyl cellulose is 40000mPa.s.

[0033] The preparation method of above-mentioned composite liquid chromium removal agent is:

[0034] A. Dissolve the formula amount of ferrous sulfate heptahydrate in the formula amount of water to form an aqueous solution of ferrous sulfate, then add the formula amount of methyl cellulose, stir for 30min, and obtain a mixed solution;

[0035] B. Add the formula amount of antimony oxychloride directly to the solution prepared in step A, stir for 60 minutes evenly, and then add the formula amount of organic solvent to obtain a composite liquid chromium remover.

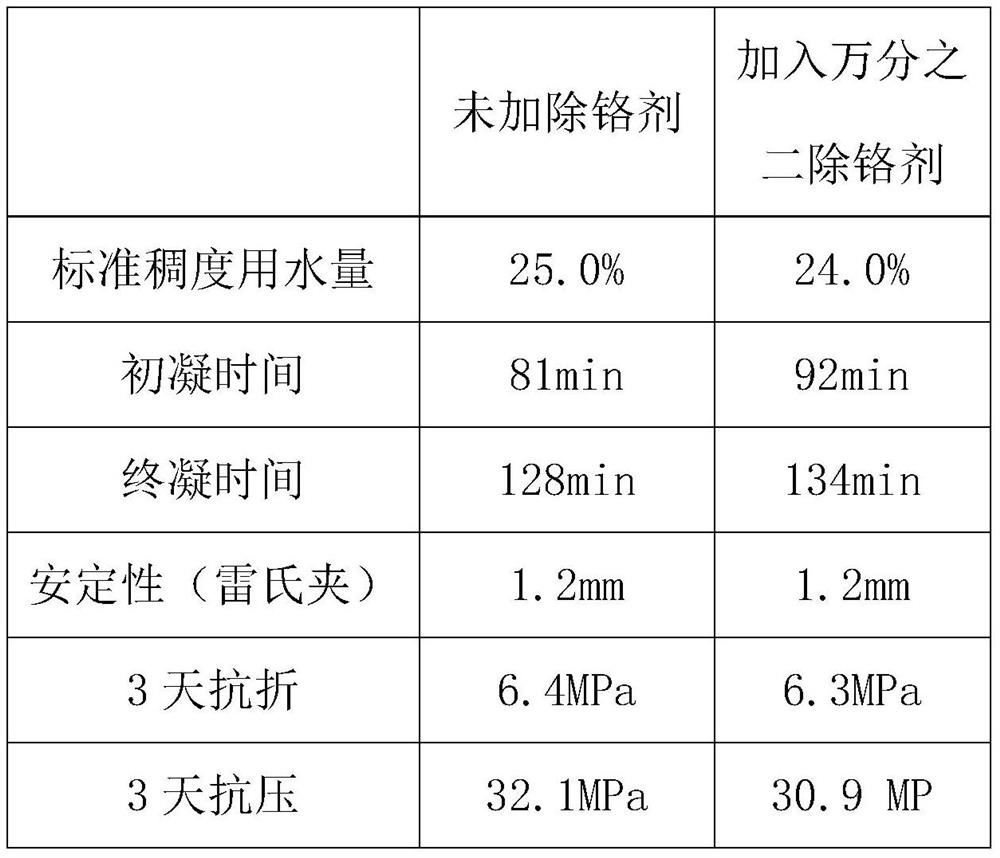

[0036] Mix 5 kg of chromium-containing clinker and 211 g of dihydrate gypsum as a sample, add the composite liquid chromium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com