Hot elution equipment and method applicable to ex-situ remediation of chromium-contaminated soil

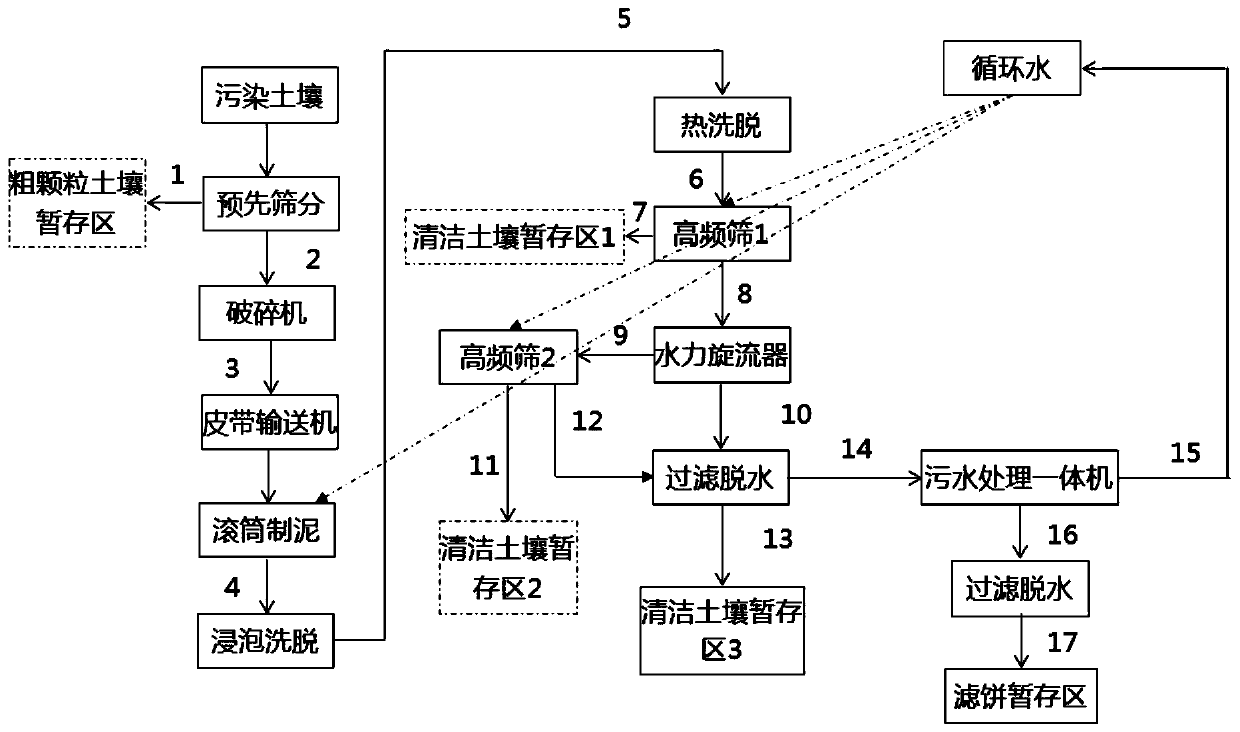

A technology of chromium-contaminated soil and washing equipment, which is applied in the restoration of polluted soil and other directions, can solve the problems of inability to meet the requirements of site remediation and high total amount of hexavalent chromium, and achieve reasonable design, simple equipment structure and operability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

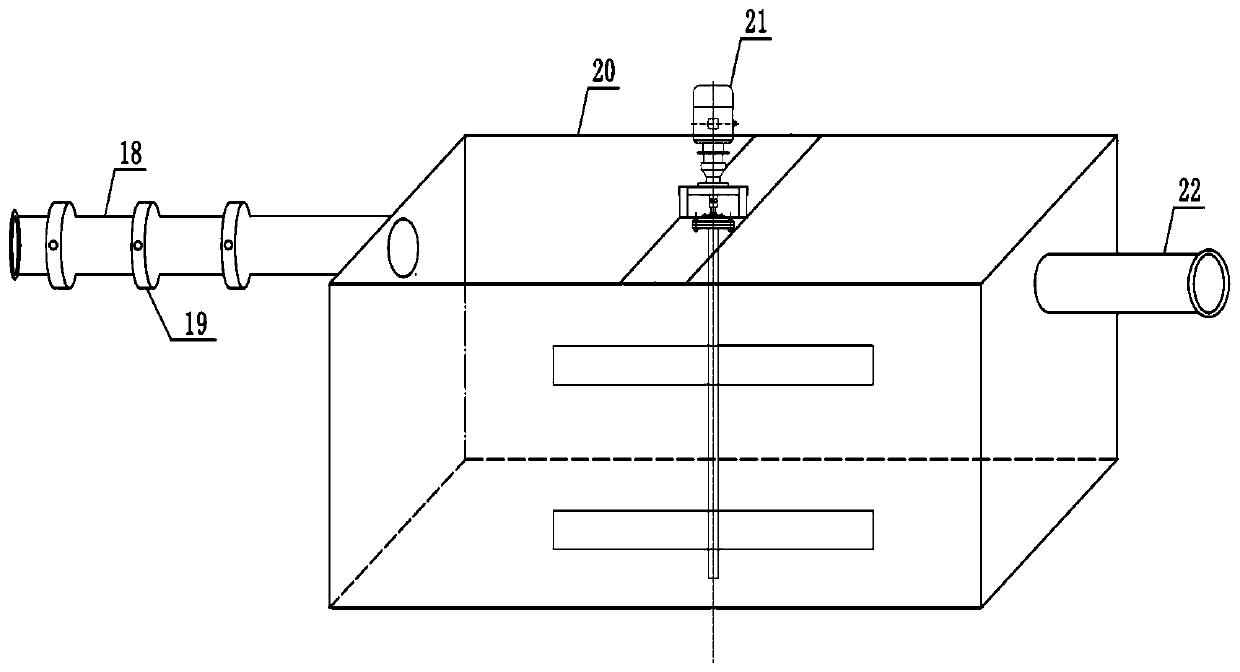

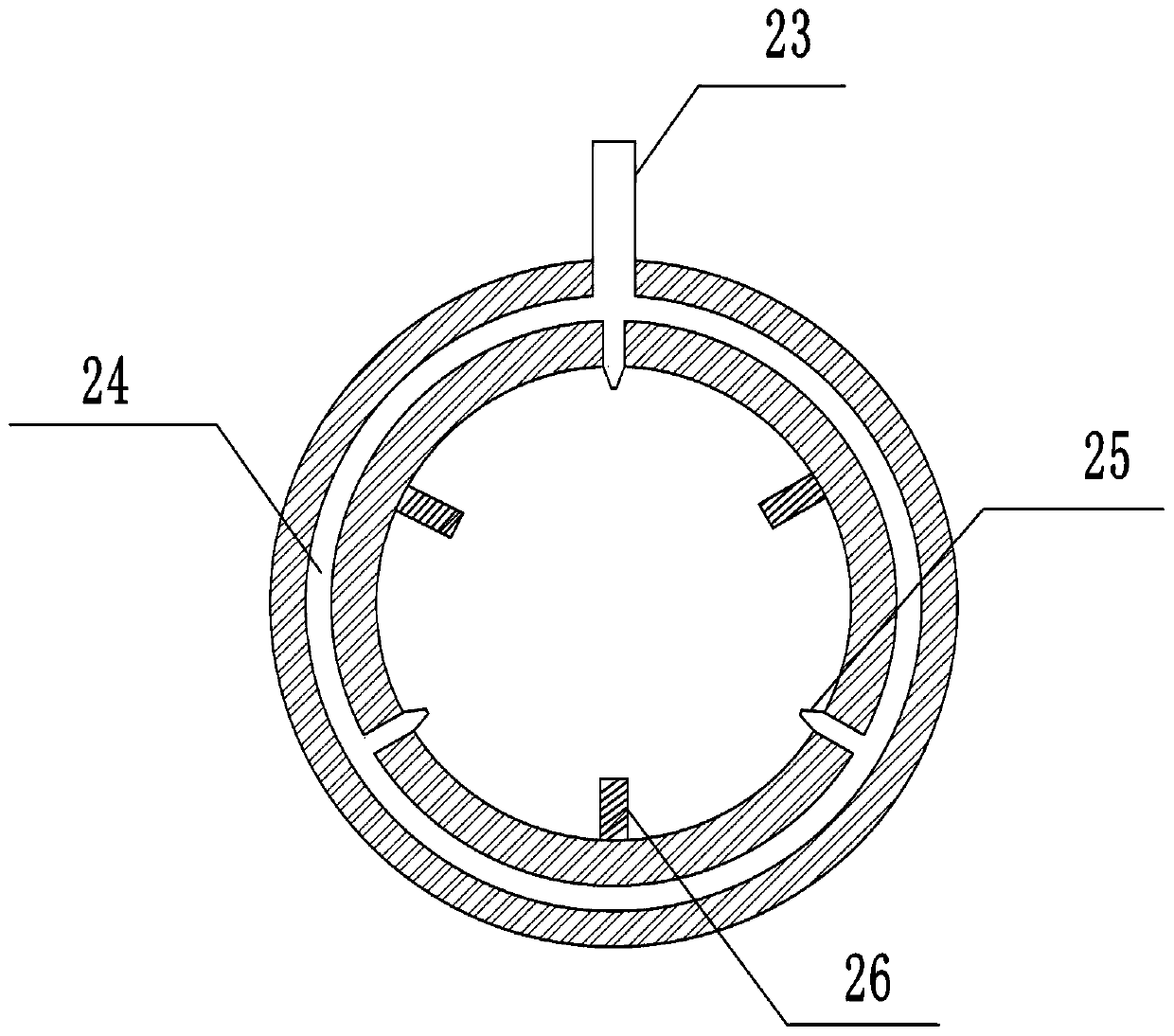

[0023] An ultrasonic rinsing device and method suitable for chromium-contaminated soil ectopic remediation of the present invention The specific implementation is shown in the accompanying drawings: the outer diameter of the heating tube (18) and the distance between the bracket (26) and the center of the heater (19) Same, the heater (19) is installed on the heating tube (18) by the bracket (26), and the heating tube (18) is connected with the front end of the heat elution pool (20) by welding, and the heat elution pool (20) is provided with The stirring motor (21) and the rear end of the heat elution pool (20) are connected with the liquid outlet pipe (22) by welding. The heating pipe (18) and the liquid outlet pipe (22) are provided with a flange, and the inner diameter of the flange is the same as the heating pipe (18) and the liquid outlet pipe (22) outer diameter. Heating pipe (18) is long 2 meters, and heater (19) is evenly distributed at intervals of 20 centimeters on h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com