Stainless steel 347 metal core welding wire with low hexavalent chrome emission and preparation method of welding wire

A hexavalent chromium, metal core technology, applied in metal processing equipment, welding equipment, welding equipment and other directions, can solve problems such as increasing welding wire production and stainless steel welding costs, reducing welding spatter, beautiful welding seam formation, welding arc stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

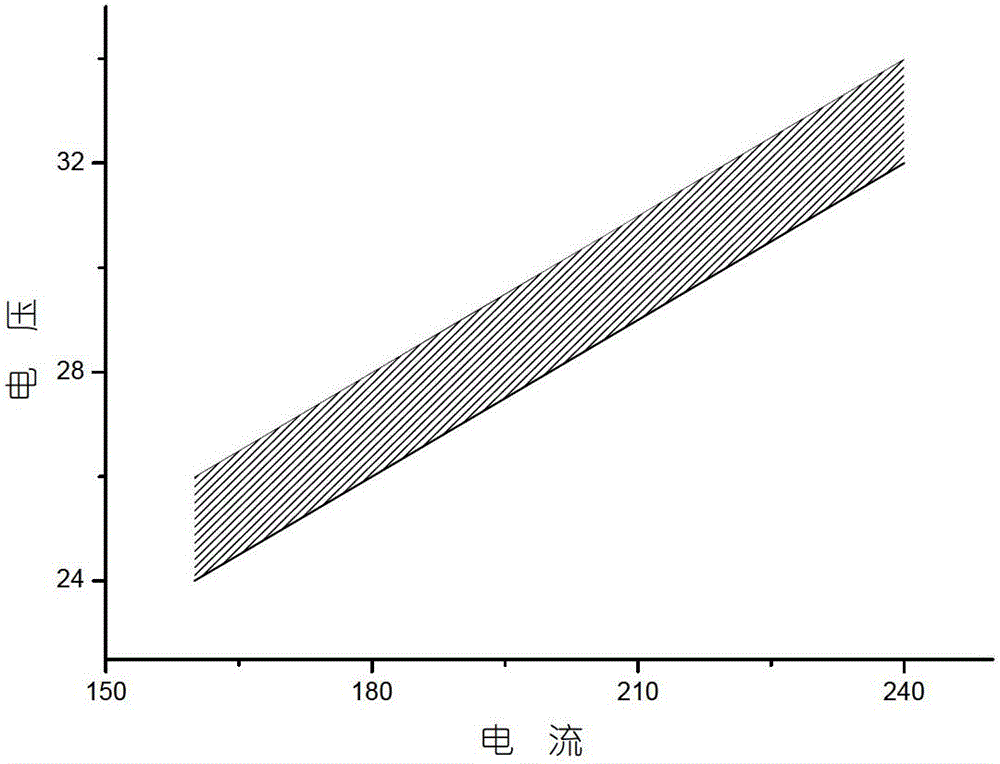

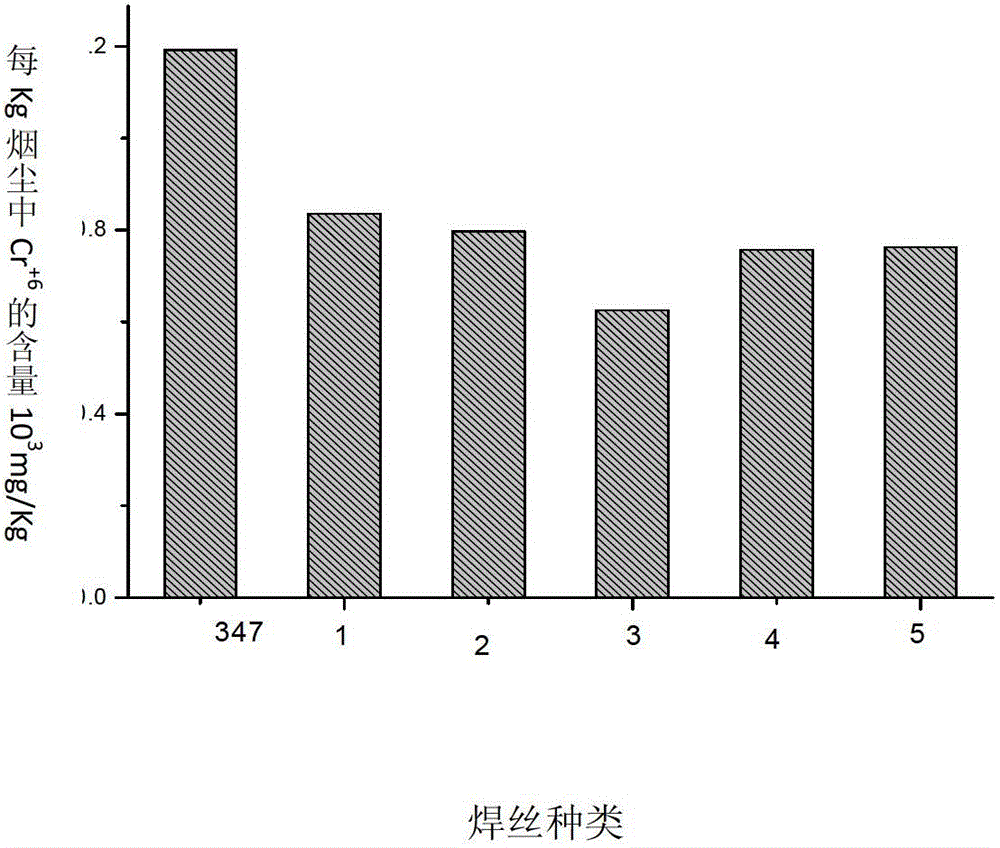

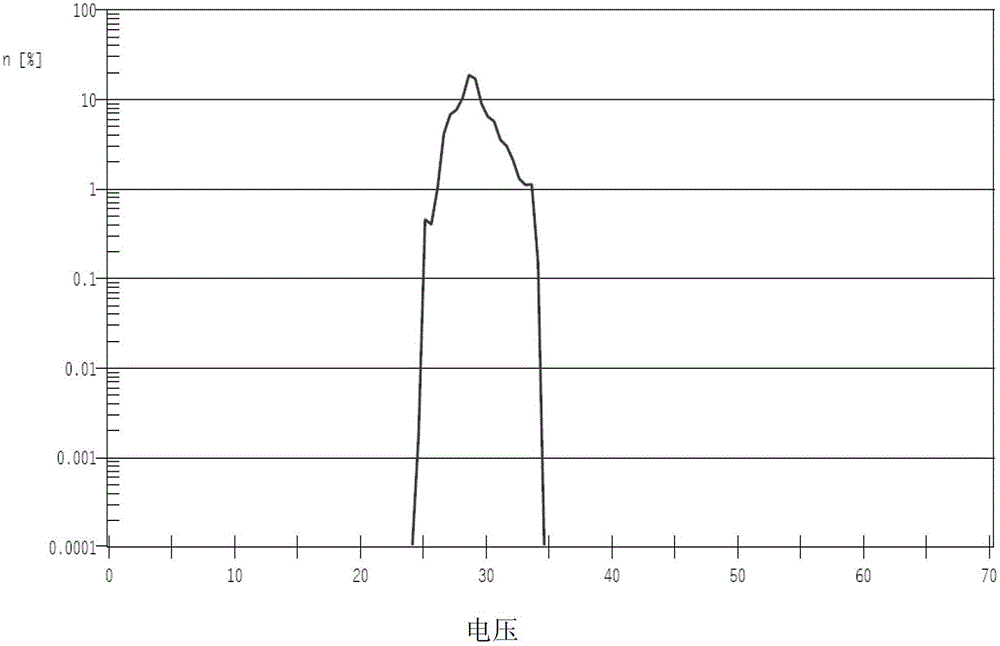

[0025] 1. A low Cr +6 The discharged stainless steel metal cored wire, relative to the total mass of the wire, contains (mass fraction wt.%): C: 0.037wt.%; Cr: 53wt.%; Ni: 27wt.%; Mn: 4wt.%; Si: 0.68wt.%; Ti: 0.6wt.%; Zn: 0.9wt.%; Zr: 0.5wt.%; Nb: 0.6; The filling rate of the powder in the steel belt is 30%. Using 98%Ar+2%O 2 The welding process parameters of gas shielded welding are: voltage 26V; current 220A; wire feeding speed 400mm / min; gas flow rate 20L / min; the distance from the welding wire to the contact tip is 20mm. The main components of the deposited metal prepared by the above process are: Cr: 20wt.%; Ni: 10wt.%; Mn: 1.8wt.%; Si: 0.45wt.%;

[0026] 2. A low Cr +6 The discharged stainless steel metal cored wire, relative to the total mass of the wire, contains (mass fraction wt.%): C: 0.025wt.%; Cr: 57wt.%; Ni: 26wt.%; Mn: 5wt.%; Si: 1 wt.%; Ti: 0.5 wt.%; Zn: 1.5 wt.%; Zr: 0.6 wt.%; Nb: 0.57 wt.%; The filling rate of the powder in the steel belt is 38%. Using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com