Low hexavalent chromium 316 austenitic stainless steel metal core welding wire and preparation method thereof

A technology of austenitic stainless steel and hexavalent chromium, applied in metal processing equipment, welding equipment, welding equipment, etc., can solve the problems of complicated solid welding wire processing technology, inability to adjust alloys, and high price of stainless steel, etc., and achieve low Hexavalent chromium, stable welding arc, and excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

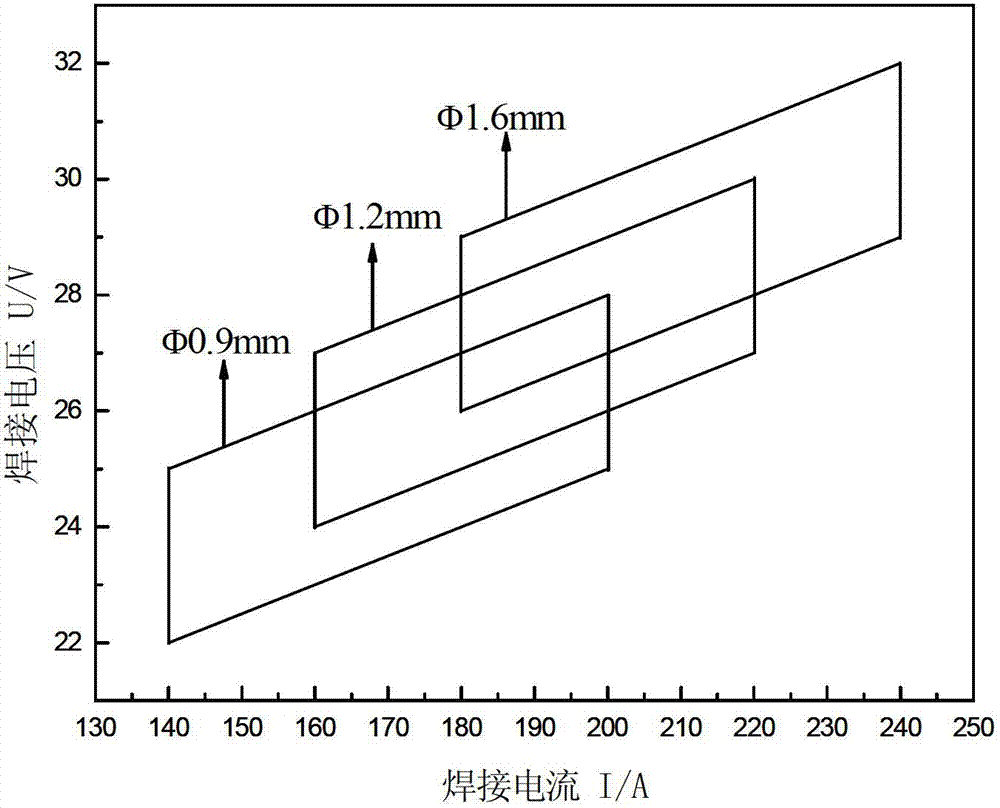

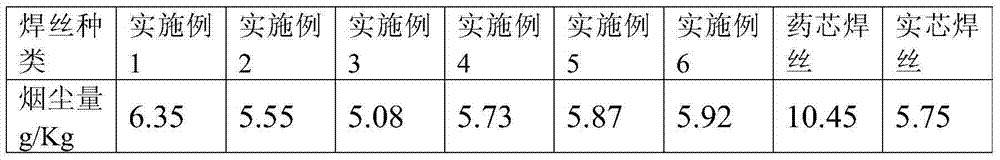

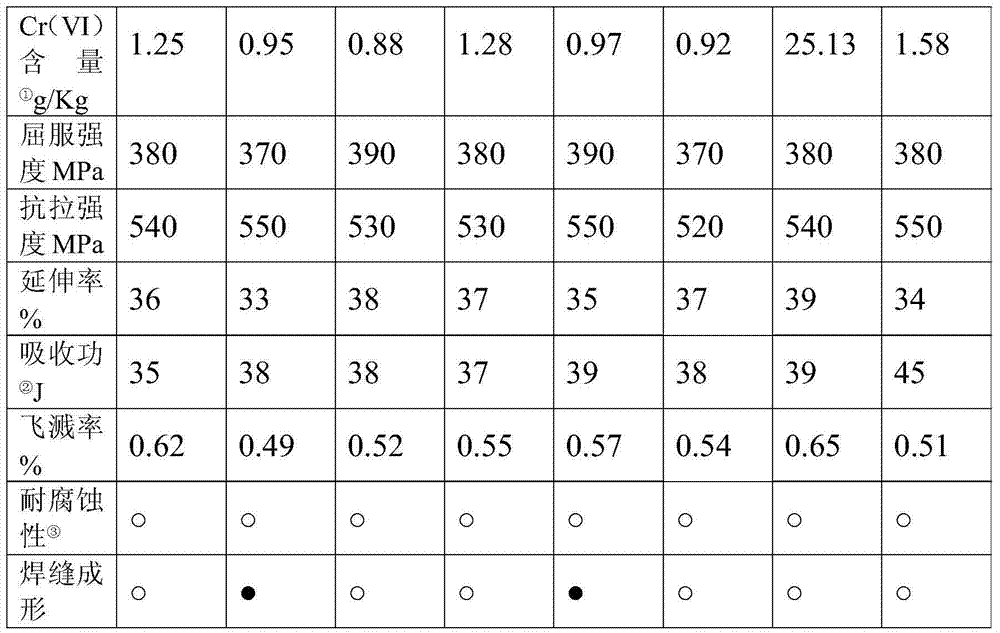

[0020] 1. A low-Cr (VI) 316 austenitic stainless steel metal-cored welding wire with a diameter of 1.6mm and a mass percentage of the chemical composition of the welding wire as follows: C: 0.025wt.%; Cr: 56wt.%; Ni: 33wt.% ; Mn: 4wt.%; Mo: 4wt%; Si: 0.86wt.%; Ti: 0.5wt.%; Zn: 0.5wt.%; The filling rate of the powder in the steel belt is 36%. Using 95%Ar+5%O 2 The welding process parameters of gas shielded welding are: voltage 28V; current 280A; wire feeding speed 500mm / min; gas flow rate 20L / min; the distance from which the welding wire extends out of the contact tip is 20mm. The composition of the deposited metal alloy prepared by the above process is: Cr: 19.3wt.%; Ni: 13wt.%; Mn: 1.2wt.%; Mo: 2.2wt.%; Si: 0.65wt.%.

[0021] 2. A low-Cr (VI) 316 austenitic stainless steel metal-cored welding wire with a diameter of 0.9mm. The mass percentage of the chemical composition of the welding wire is as follows: C: 0.078wt.%; Cr: 59wt.%; Ni: 36wt.%; Mn : 6.1wt.%; Mo: 4.5wt%; Si: 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com