Chromium residue wet detoxication processing method

A technology of wet detoxification and treatment method, which is applied in the direction of protection devices against harmful chemical agents, etc., which can solve the problems of difficult filtration, large acid consumption, and high treatment cost, and achieve the effect of reducing costs and ensuring the effect of detoxification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

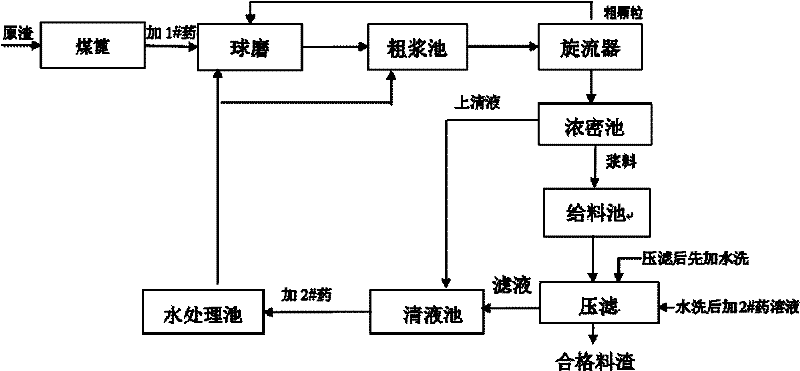

Method used

Image

Examples

Embodiment 1

[0022] At room temperature of 18°C, first add 5kg of chromium slag, 2.0kg of water and 120g of sodium bicarbonate into a ball mill and mill for 40 minutes, then add 4.0kg of water to adjust the concentration to 30% and pass through a 200-mesh sieve, and the slurry under the sieve reacts for 3 hours , into a plate and frame filter press with water washing for dehydration by pressing, washing with water for 10 minutes, and finally washing with saturated ferrous sulfate solution for 3 minutes. The hexavalent chromium content in the initial filtrate was detected to be 2452ppm. In 2007, the leaching solution prepared by the toxic leaching method of solid wastes measured 0.07ppm of hexavalent chromium and 0.1ppm of total chromium, meeting the standard requirements for general solid waste landfill in HJ / T301-2007 "Technical Specifications for Environmental Protection of Chromium Slag Pollution Control" .

Embodiment 2

[0024] At room temperature of 2°C, add 5kg of slag, 2.0kg of water and 120g of sodium bicarbonate into a ball mill and mill for 40 minutes, then add 4.0kg of water to adjust the concentration to 30% and pass through a 200-mesh sieve, and the slurry under the sieve reacts for 3 hours Enter the plate and frame filter press with water washing for dehydration and washing for 10 minutes, and finally wash with saturated barium chloride solution for 2 minutes. The hexavalent chromium content in the initial filtrate is 2273ppm, and the filter cake is solid according to HJ / T 299-2007 Toxic leaching method of waste leaching The leaching solution is prepared by measuring hexavalent chromium 0.06ppm, total chromium 0.1 ppm, and barium 25ppm, which meet the standard requirements of entering general solid waste landfill in HJ / T301-2007 "Technical Specifications for Environmental Protection of Chromium Slag Pollution Control" .

Embodiment 3

[0026] At room temperature of 2°C, add 5kg of slag, 2.0kg of water and 120g of sodium carbonate into a ball mill and mill for 40 minutes, then add 4.0kg of water to adjust the concentration to 30% and pass through a 200-mesh sieve. The slurry under the sieve reacts for 3 hours before entering The plate and frame filter press with water washing is used for dehydration and washing for 10 minutes, and finally washed with saturated ferrous sulfate solution for 3 minutes. The hexavalent chromium content in the initial filtrate is 2268ppm, and the filter cake is solid waste according to HJ / T 299-2007 Leaching Toxicity Leaching method The leaching solution was prepared to measure 0.06ppm of hexavalent chromium and 0.09ppm of total chromium, meeting the standard requirements for entering general solid waste landfill in HJ / T301-2007 "Technical Specifications for Environmental Protection of Chromium Slag Pollution Control".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com