Zinc-steel fence connecting piece with surfaces sprayed with graphene coating

A technology of surface spraying and connecting parts, applied in anti-corrosion coatings, construction materials processing, coating and other directions, can solve problems such as affecting appearance, rust spots, hidden dangers, etc., to reduce production costs, reduce pigment costs, and improve performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

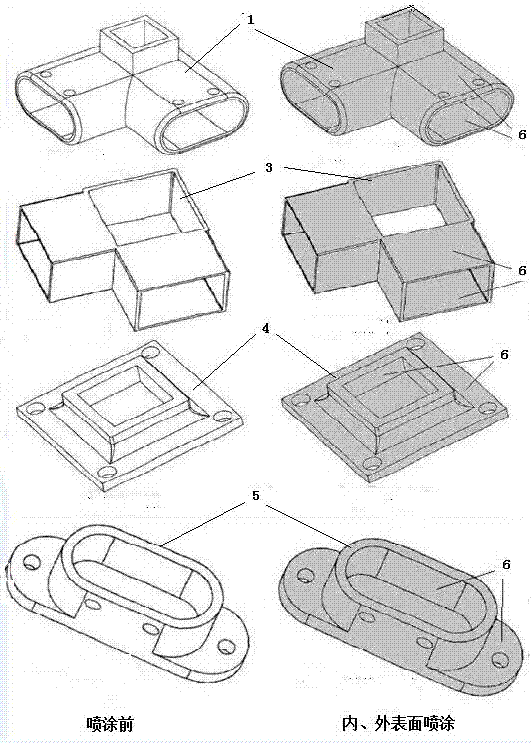

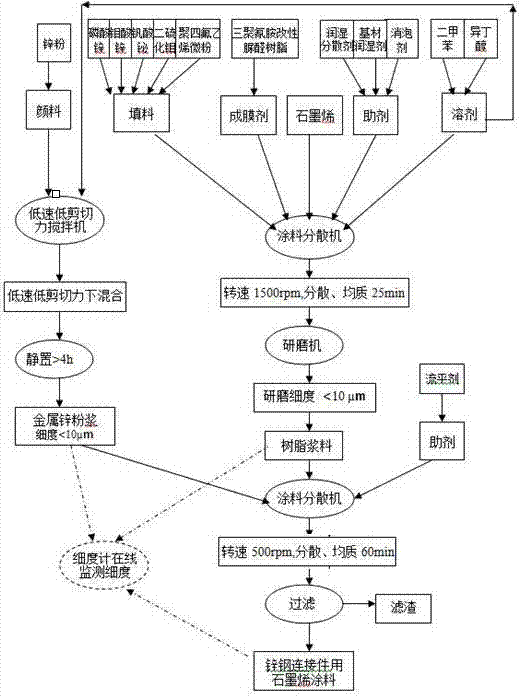

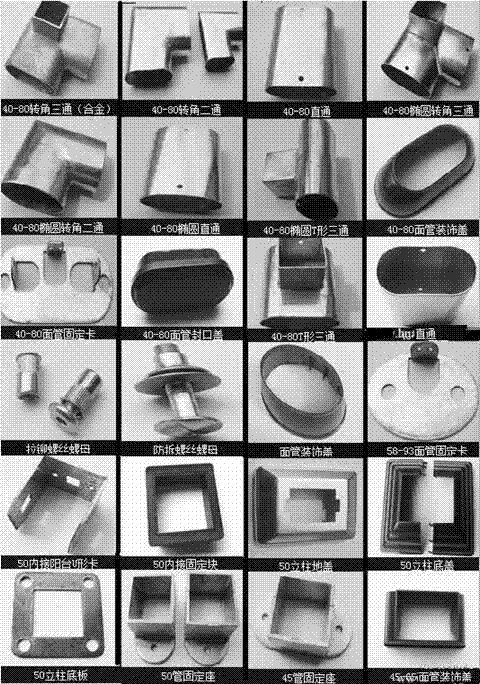

[0019]In conjunction with the accompanying drawings, the specific embodiment is: a zinc-steel guardrail connector whose surface is sprayed with a graphene coating, which is characterized in that the prepared graphene coating 6 suitable for the zinc-steel guardrail connector is sprayed on the zinc-steel guardrail connector. The outer surface of the guardrail connector or the outer surface of the guardrail combined with the connector, or the inner and outer surfaces of the connector, the coating thickness is 12μm±; figure 2 As shown, the corner tee connector 1, the corner two-way connector 2, the tee connector 3, and the base connector 4 that have been combined with the guardrail and are being used are sprayed with a graphene coating 6 with a thickness of 12 μm± , or combined with it on the outer surface of the guardrail including the connector, the spraying thickness is 12μm ± graphene coating 6; among them, according to the attached ima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com