Surface treatment solution for magnesium alloy material and technique for processing magnesium alloy material surface

A surface treatment, magnesium alloy technology, applied in the direction of metal material coating process, can solve the problems of large environmental pollution, high cost, rapid solution consumption, etc., to achieve strong anti-corrosion ability, strong adhesion, no heavy metal toxicity and pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

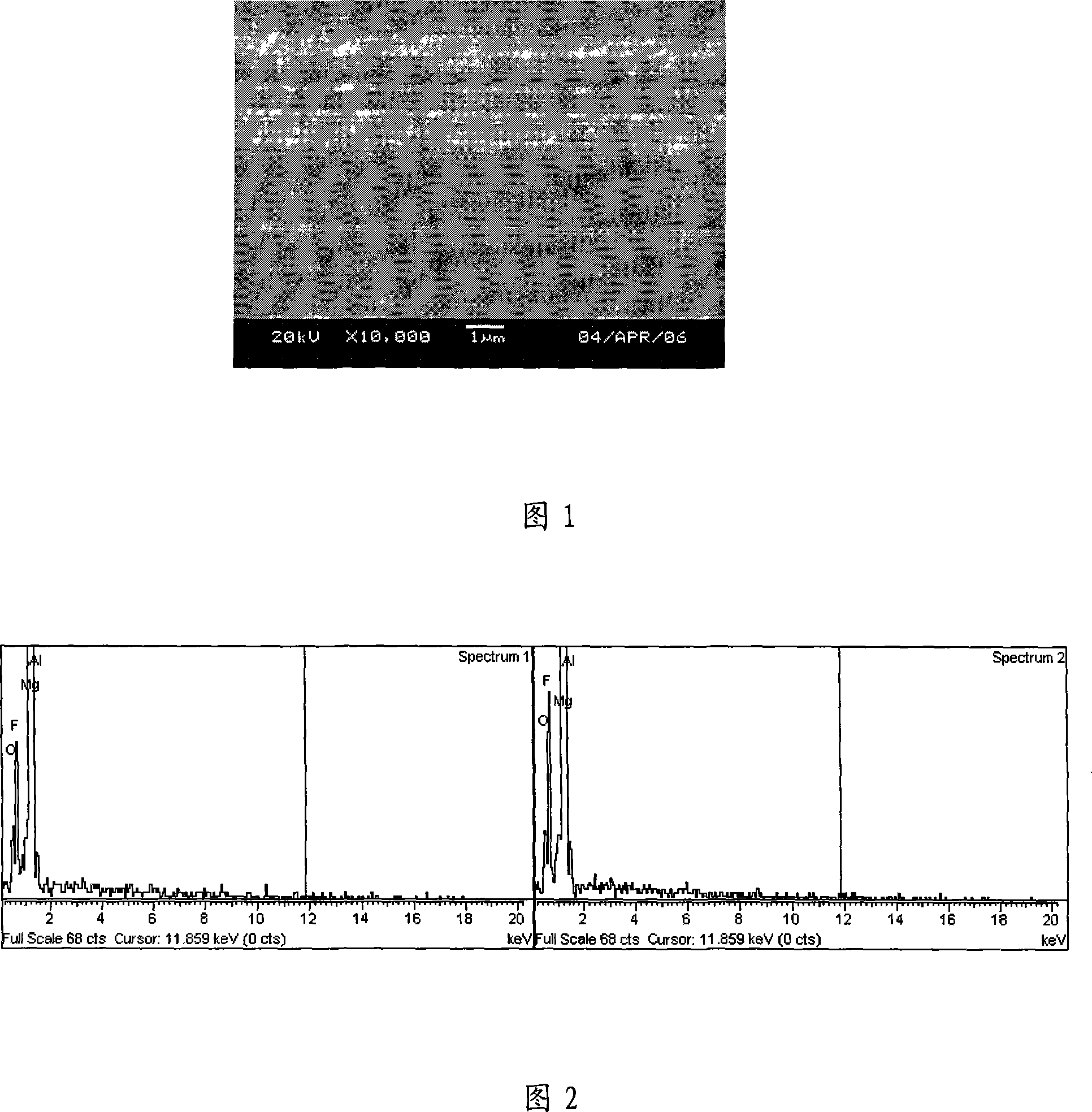

Image

Examples

Embodiment 1

[0029] Configure the treatment solution of the present invention according to Table 1:

[0030] Table 1: Components of the treatment solution

[0031]

Element

Concentration (g / l)

Recipe 1

Recipe 2

Recipe 3

3.15

3.20

3.45

10.0

11.0

11.5

1.00

1.50

2.50

4.00

4.50

5.25

2.00

2.20

2.30

water

margin

margin

margin

[0032] The grade is AZ31 extruded magnesium alloy, and the following steps are carried out for surface treatment of extruded magnesium alloy products:

[0033] 1. Mechanical decontamination: use sandblasting or sandpaper to polish, remove burrs, oxides, extrusion additives, processing oil and other foreign matter, and wash with water;

[0034] 2. Alkaline washing and degreasing: wash wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com