A kind of non-phosphorus and slag-free normal temperature coating agent

A coating agent, room temperature technology, applied in the field of environmentally friendly non-phosphorus, slag-free and normal temperature coating agents, can solve problems such as harming human health, polluting the environment, toxicity, etc., to save costs, solve pollution problems, and achieve good compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] The components of the phosphorus-free and slag-free normal temperature coating agent are:

[0037] A component is:

[0038] Fluorozirconic acid 40g / L;

[0039] Hydrofluoric acid 400g / L;

[0040] The solvent is water.

[0041] B components are:

[0042] Magnesium nitrate 400g / L;

[0043] Hydrogen peroxide 6g / L;

[0044] The solvent is water.

[0045] Wherein, the mass fraction of fluozirconic acid is 40%, the mass fraction of hydrofluoric acid is 55%, the mass fraction of hydrogen peroxide is 35%, and the magnesium nitrate is magnesium nitrate hexahydrate.

[0046] Take 25gA and 20gB and mix, then add water to 1L, and stir well to get phosphorus-free and slag-free room temperature coating agent solution, control the total acidity to 13.5±0.6 points, and the free acidity to 10±0.4 points.

[0047] First, degrease the surface of the aluminum material to remove the grease and impurities on the surface. After washing twice, put the aluminum material into the above-men...

example 2

[0050] The components of the phosphorus-free and slag-free normal temperature coating agent are:

[0051] A component is:

[0052] Fluorozirconic acid 35g / L;

[0053] Hydrofluoric acid 300g / L;

[0054] The solvent is water.

[0055] B components are:

[0056] Magnesium nitrate 350g / L;

[0057] Hydrogen peroxide 5g / L;

[0058] The solvent is water.

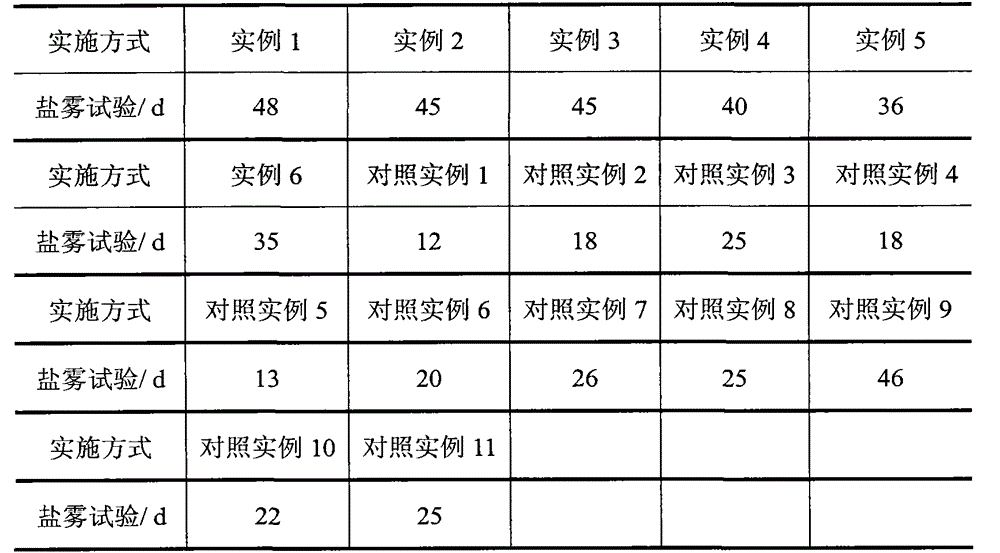

[0059] Get 25gA and 20gB to mix, the preparation and the method of use of non-phosphorus and slag-free normal temperature coating agent solution are the same as example 1. According to the GB / T1771-2007 standard, the neutral salt spray test of the aluminum paint film is carried out, and the test results are shown in the attached table.

example 3

[0061] The components of the phosphorus-free and slag-free normal temperature coating agent are:

[0062] A component is:

[0063] Fluorozirconic acid 36g / L;

[0064] Hydrofluoric acid 260g / L;

[0065] The solvent is water.

[0066] B components are:

[0067] Magnesium nitrate 340g / L;

[0068] Hydrogen peroxide 4g / L;

[0069] The solvent is water.

[0070] Get 30gA and 18gB to mix, and the preparation and the method of use of non-phosphorus and slag-free normal temperature coating agent solution are the same as example 1. According to the GB / T1771-2007 standard, the neutral salt spray test of the aluminum paint film is carried out, and the test results are shown in the attached table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com