A kind of calcium/aluminum ion-exchange silica gel doped with rare earth element and preparation method thereof

A rare earth element and aluminum ion technology, applied in the field of chemistry, can solve the problems of high energy consumption in the production process, good doping effect, complicated operation steps, etc., and achieve the improvement of acid and alkali resistance, reduce potential safety hazards, and improve environmental friendliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

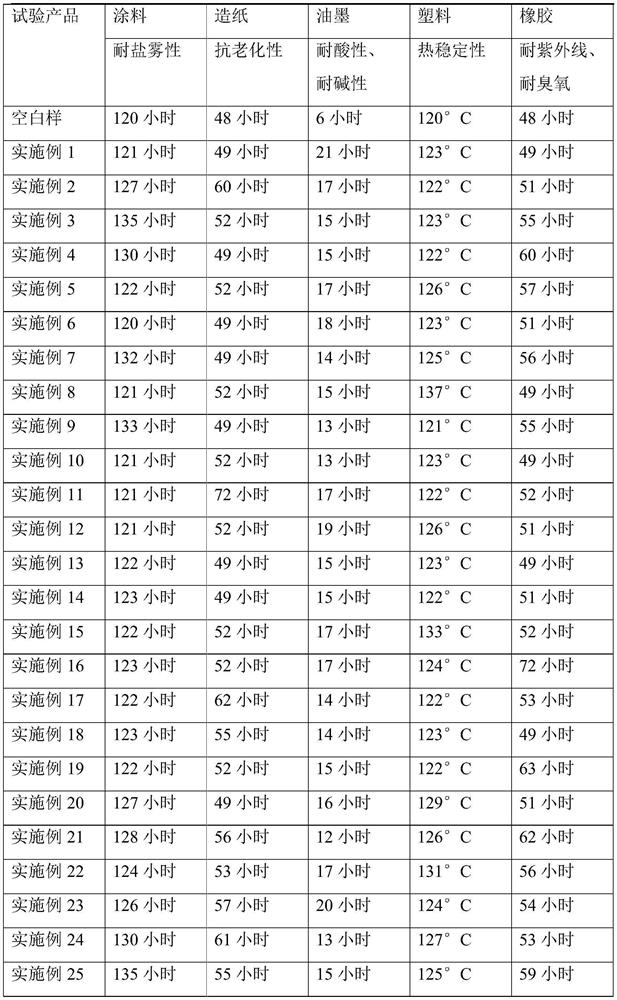

Examples

Embodiment 1

[0024] The preparation method of the calcium / aluminum ion-exchange silica gel doped with rare earth elements of the present invention comprises the following steps:

[0025] A. Disperse 2.0kg of calcium carbonate in water to obtain dispersion A; disperse 0.5kg of alumina in water to obtain dispersion B; disperse 5.0kg of silicic acid in water to obtain dispersion C;

[0026] B. Put Dispersion A, Dispersion B and Dispersion C into the autoclave, then add 0.1kg of lanthanum nitrate, mix well; dropwise add sodium hydroxide solution, adjust the pH value of the mixture to 10; Under hydrothermal reaction 12 hours, obtain reaction product;

[0027] C. The reaction product was filtered, washed, and dried at 50°C to obtain a precursor; the precursor was crystallized at 375°C for 0.5 hours to obtain a product.

Embodiment 2

[0029] The preparation method of the calcium / aluminum ion-exchange silica gel doped with rare earth elements of the present invention comprises the following steps:

[0030] A. Disperse 1.5kg of calcium hydroxide in water to obtain dispersion A; disperse 2.0kg of aluminum hydroxide in water to obtain dispersion B; disperse 5.0kg of silica sol in water to obtain dispersion C;

[0031] B. Put Dispersion A, Dispersion B and Dispersion C into the autoclave, then add 0.01kg of yttrium oxide and mix evenly; add ammonia water and calcium hydroxide solution dropwise, and adjust the pH value of the mixture to 10.5; Under the condition of hydrothermal reaction for 8 hours, the reaction product was obtained;

[0032] C. The reaction product was filtered, washed, and dried at 100°C to obtain a precursor; the precursor was crystallized at 260°C for 7 hours to obtain a product.

Embodiment 3

[0034] The preparation method of the calcium / aluminum ion-exchange silica gel doped with rare earth elements of the present invention comprises the following steps:

[0035] A. Disperse 0.6 kg of calcium nitrate and 1.07 g of calcium hydroxide in water to obtain mixed solution A; disperse 1.1 kg of aluminum oleate in water to obtain dispersion B; disperse 5.0 kg of silicon-soluble sodium in water to obtain dispersion C;

[0036] B. Put the mixed liquid A, dispersion liquid B and dispersion liquid C into the autoclave, then add 0.0005kg samarium hydroxide and mix well; add potassium hydroxide solution dropwise to adjust the pH value of the mixed liquid to 9.5; Under hydrothermal reaction for 8.5 hours, the reaction product was obtained;

[0037] C. The reaction product was filtered, washed, and dried at 135°C to obtain a precursor; the precursor was crystallized at 220°C for 5.5 hours to obtain a product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com