Zinc-rich epoxy anticorrosion paint and preparation method thereof

A technology of anti-corrosion coatings and zinc-rich epoxy, which is applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of complex graphene addition steps, achieve good chemical stability, wide application range, and reduce content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] A kind of preparation method of anticorrosion epoxy resin coating, comprises the steps:

[0074] 1, the preparation method of described anticorrosion paint first component is:

[0075] (1) Add the amount of epoxy resin formulated in Group A into the stirring container, and stir at a speed of 1000-1500r / min;

[0076] (2) Then add the solvent, zinc powder, graphene and filler in the formula of Part A in sequence, and continue to stir at the speed of 2000-3000r / min until the dispersion is uniform;

[0077] (3) Add the mixture obtained in step (2) into a three-stage grinder and grind it to 20-60 μm to obtain component A;

[0078] II, the preparation method of the second component of the anticorrosion coating is:

[0079] (4) A mixed solvent made of xylene and isobutanol at a weight ratio of 1:1 is used as the solvent for component B. Sequentially mix the curing agent and the solvent in the formulation amount of component B to obtain component B;

[0080] III. Mix the pr...

Embodiment 5

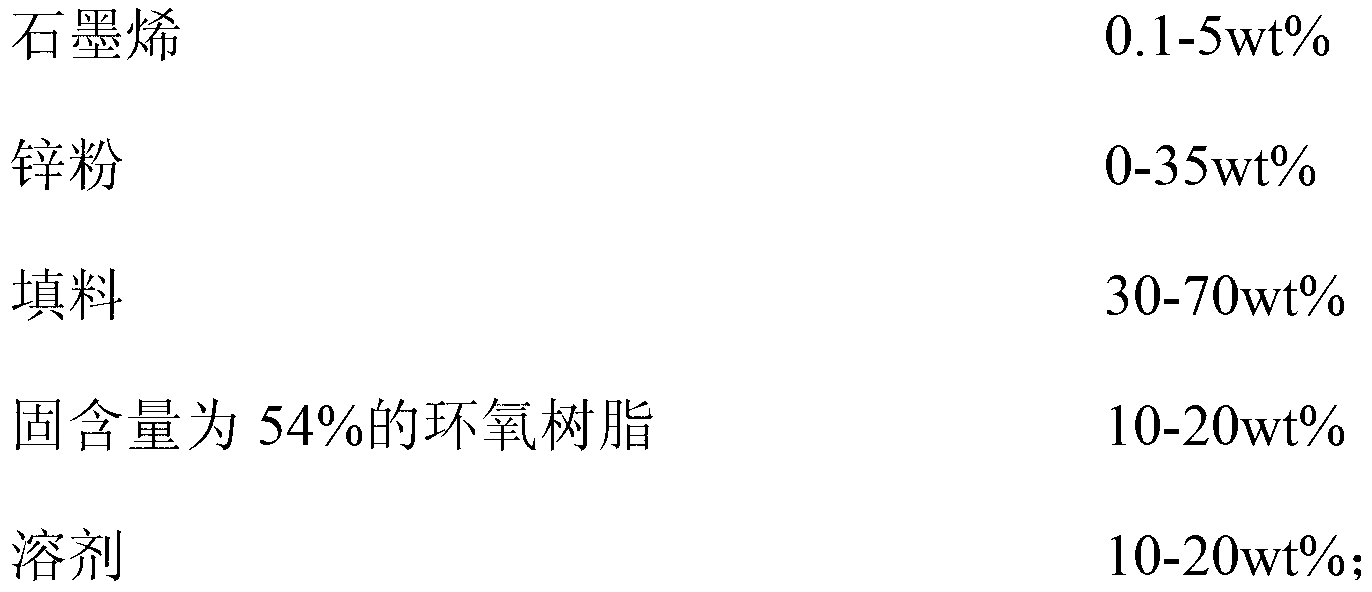

[0087] A kind of anticorrosion epoxy resin coating comprises following component by weight percentage:

[0088]

[0089] Wherein, the epoxy resin is SM-601 epoxy resin with a solid content of 54% (the dispersion solvent is xylene), and the sum of the mass percentages of graphene, zinc powder and filler is 60wt%; the graphene It is oxidized by the Staudenmaier method, and then obtained by pyrolytic expansion and peeling;

[0090] B component:

[0091] Polyamide resin curing agent 40wt%

[0092] Xylene and isobutanol m:m=1:1 (fixed) 60wt%;

[0093] Wherein, the sum of each component in the B component is 100wt%.

[0094] The preparation method of described anticorrosion epoxy resin coating comprises the steps:

[0095] (1) Add the amount of epoxy resin formulated in Part A into the stirring container, and stir at a speed of 1500r / min;

[0096] (2) Then add the solvent, zinc powder, graphene and filler in the formula of Part A in sequence, and continue to stir at the spee...

Embodiment 6

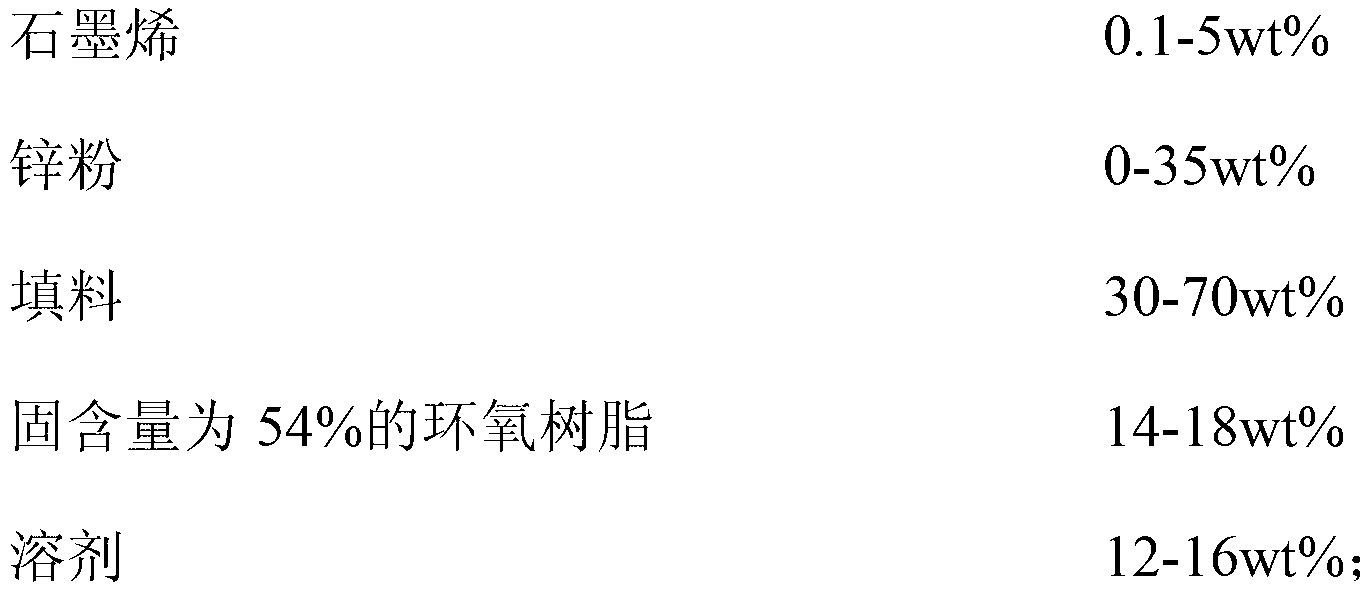

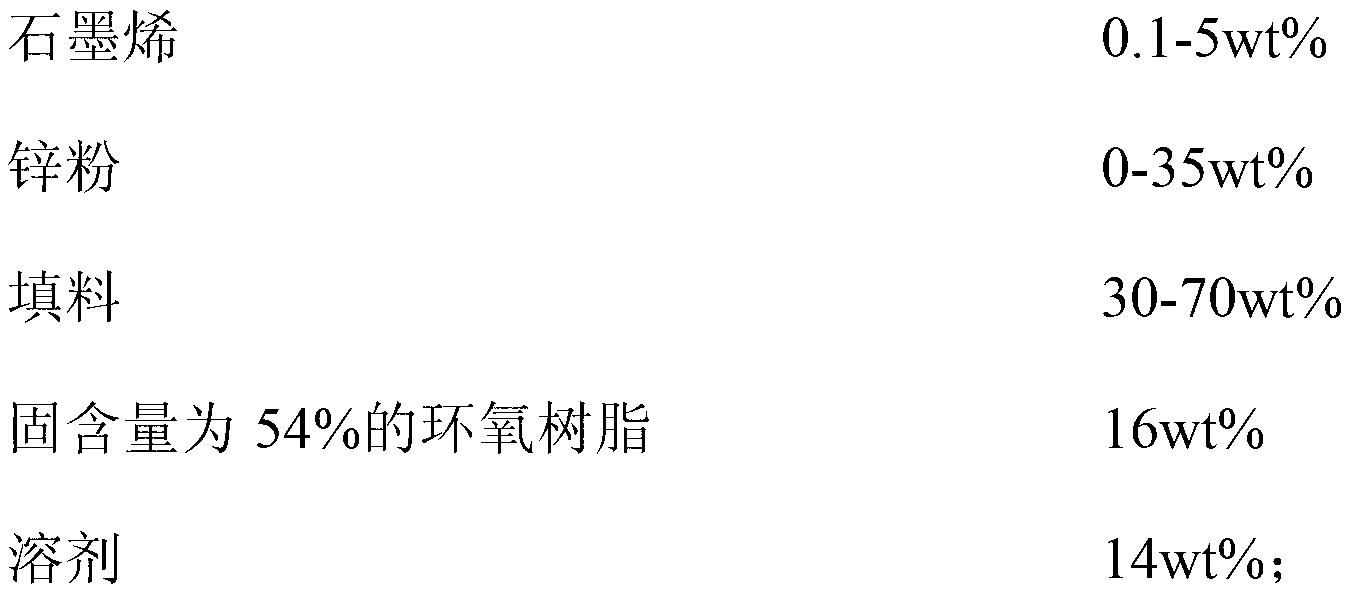

[0102] A kind of anticorrosion epoxy resin coating comprises following component by weight percentage:

[0103] Component A:

[0104]

[0105] Wherein, the epoxy resin is SM-601 epoxy resin with a solid content of 54% (the dispersion solvent is xylene), and the sum of the mass percentages of graphene, zinc powder and filler is 80wt%; the graphene It is oxidized by Brodie method, and then obtained by ultrasonic dispersion;

[0106] B component:

[0107] Acrylic resin curing agent 60wt%

[0108] Xylene and isobutanol (m:m=1:1) 40wt%;

[0109] Wherein, the sum of each component in the B component is 100wt%.

[0110] The preparation method of described anticorrosion epoxy resin coating comprises the steps:

[0111] (1) Add the amount of epoxy resin formulated in Part A into the stirring container, and stir at a speed of 1000r / min;

[0112] (2) Then add the solvent, zinc powder, graphene and filler in the formula of Part A in sequence, and continue to stir at the speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com