Metal surface degreasing agent and preparation method and application thereof

A metal surface and degreasing agent technology, applied in the field of metal surface degreasing agent, can solve problems such as instability, and achieve the effects of low cost, low foam and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

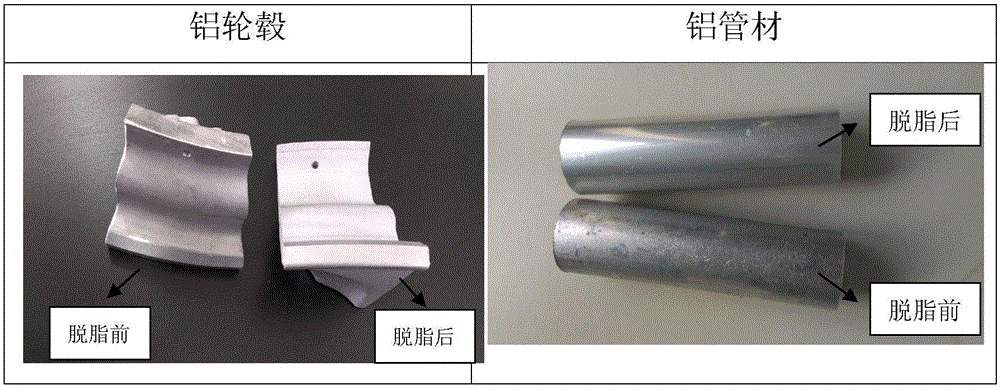

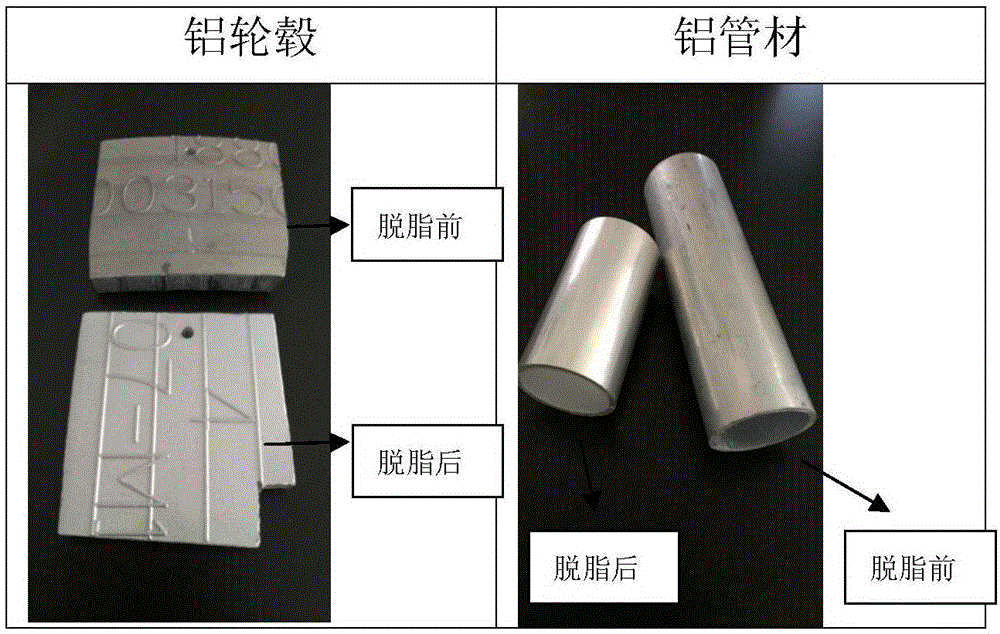

Image

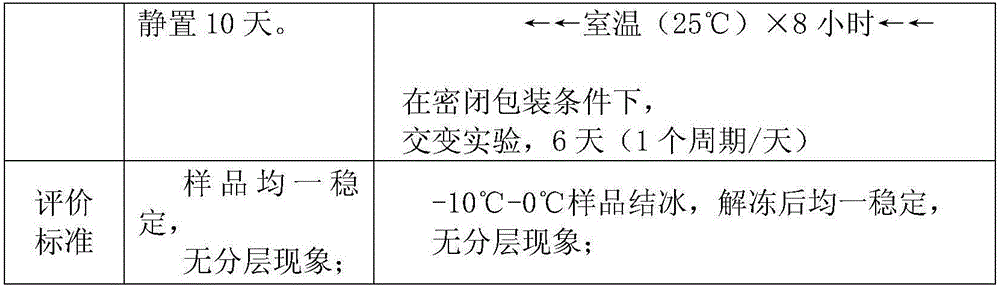

Examples

Embodiment 1

[0034] Agent A raw material is composed of the following substances by mass percentage:

[0035]

[0036] The preparation method is as follows: taking deionized water with a mass percentage of 48%, adding the above-mentioned medicaments in sequence according to the proportion under the stirring condition of medium speed (400r / min), and stirring evenly.

[0037] B agent raw material is composed of the following substances by mass percentage:

[0038]

[0039] The preparation method is: take deionized water with a mass percentage of 80%, add potassium carbonate with a mass percentage of 0.1% and HB-1380 with a mass percentage of 0.1% and 15% HB-1380 under a medium speed (400r / min) stirring condition, and stir for 10-20min to mix evenly Finally, add 5% HB-126 by mass and stir evenly.

[0040] The surfactants used in the examples of the present invention are HB-1380 (isomeric tridecyl alcohol polyoxyethylene ether) and HB-126 (polymerization product of cyclopropane and cycl...

Embodiment 2

[0042] Agent A raw material is composed of the following substances by mass percentage:

[0043]

[0044]

[0045] The preparation method is as follows: taking deionized water with a mass percentage of 54%, adding the above-mentioned medicaments in sequence under the stirring condition of medium speed (400r / min), and stirring evenly.

[0046] B agent raw material is composed of the following substances by mass percentage:

[0047]

[0048] The preparation method is: take deionized water with a mass percentage of 80.3%, add potassium carbonate with a mass percentage of 0.2% and HB-1380 with a mass percentage of 10% under a medium speed (400r / min) stirring condition, and stir for 10-20min to mix evenly Finally, add HB-126 with a mass percentage of 9.5%, and stir evenly.

Embodiment 3

[0050] Agent A raw material is composed of the following substances by mass percentage:

[0051]

[0052] The preparation method is as follows: taking deionized water with a mass percentage of 62%, adding the above-mentioned medicaments in sequence according to the proportioning under the medium-speed (400r / min) stirring condition, and stirring evenly.

[0053] B agent raw material is composed of the following substances by mass percentage:

[0054]

[0055] The preparation method is: take deionized water with a mass percentage of 74.7%, add potassium carbonate with a mass percentage of 0.3% and HB-1380 with a mass percentage of 0.3% and 15% HB-1380 under a medium speed (400r / min) stirring condition, stir for 10-20min and mix well Finally, add HB-126 with a mass percentage of 10%, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com