Preparation method of asphalt regenerating agent

A kind of asphalt regeneration agent and catalyst technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of short service life of recycled asphalt pavement, inability to dissolve and disperse asphaltene, etc., and achieve surface energy reduction, surface Effect of reducing tension and improving fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

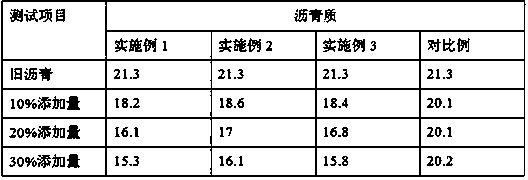

Examples

preparation example Construction

[0023] A preparation method of an asphalt regenerant, the preparation method comprising the steps of:

[0024] (1) In parts by weight, take 15-20 parts of isophorone diisocyanate, 7-8 parts of fatty alcohol polyoxyethylene ether, 5-6 parts of N-methyldiethanolamine, 3-4 parts of acetone, 3 ~4 parts of 0.1mol / L acetic acid solution, 0.01~0.03 parts of organotin catalyst, put isophorone diisocyanate and N-methyldiethanolamine into a container for mixing, pass through nitrogen protection, and add organotin while stirring Catalyst, heat up to 80~85°C, stir for 1~2h, wait until the temperature drops to 70~75°C, add fatty alcohol polyoxyethylene ether, acetone, keep warm for 1~2h, wait to cool to room temperature, add acetic acid solution, with 1000~ Disperse and emulsify at a speed of 2000r / min for 10~15min, adjust the solid content to 30%, and obtain a dispersion for later use;

[0025] (2) Dry the red mud naturally for 2~4 hours, crush it to get the crushed product, mix the crus...

Embodiment 1

[0029] The organotin catalyst is dibutyltin dilaurate.

[0030] The base asphalt is 70# new asphalt.

[0031] The modified bentonite is mixed with calcium-based bentonite and water according to the mass ratio of 1:10, soaked for 1 hour, added sodium pyrophosphate with 0.3% of the mass of calcium-based bentonite, and roughly dispersed under a high-speed disperser, and then carried out under ultrasonic waves. Finely disperse and filter to obtain filter residue, wash the filter residue with water and dry to obtain modified bentonite.

[0032] The mixture is uniformly mixed with nonylphenol polyoxyethylene ether and sodium lauryl sulfate at a mass ratio of 5:3 to obtain the mixture.

[0033] The plasticizer refers to dibutyl phthalate.

[0034] A preparation method of an asphalt regenerant, the preparation method comprising the steps of:

[0035] (1) In parts by weight, take 15 parts of isophorone diisocyanate, 7 parts of fatty alcohol polyoxyethylene ether, 5 parts of N-methyl...

Embodiment 2

[0040] The organotin catalyst is stannous octoate.

[0041] The base asphalt is 70# new asphalt.

[0042] The modified bentonite is to mix calcium-based bentonite and water according to the mass ratio of 1:15, soak for 2 hours, add sodium pyrophosphate with 0.4% of the mass of calcium-based bentonite, and carry out coarse dispersion under a high-speed disperser, and then proceed under ultrasonic waves. Finely disperse and filter to obtain filter residue, wash the filter residue with water and dry to obtain modified bentonite.

[0043] The mixture is uniformly mixed with nonylphenol polyoxyethylene ether and sodium lauryl sulfate at a mass ratio of 5:3 to obtain the mixture.

[0044] The plasticizer refers to dibutyl phthalate.

[0045] A preparation method of an asphalt regenerant, the preparation method comprising the steps of:

[0046] (1) In parts by weight, take 20 parts of isophorone diisocyanate, 8 parts of fatty alcohol polyoxyethylene ether, 6 parts of N-methyldieth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com