Manufacturing method of light-stability agent

A technology of light stabilizer and manufacturing method, applied in the direction of organic chemistry, etc., can solve problems such as unpublished reports, inability to meet high-end customers, etc., to overcome color development factors, improve distillate yield and quality, and fast side reaction products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

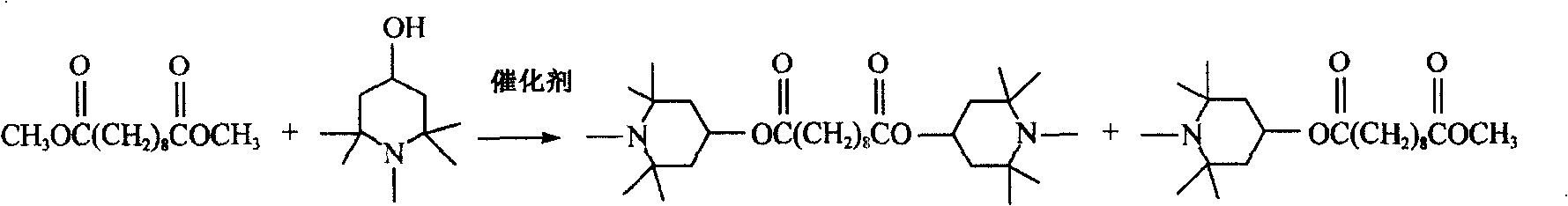

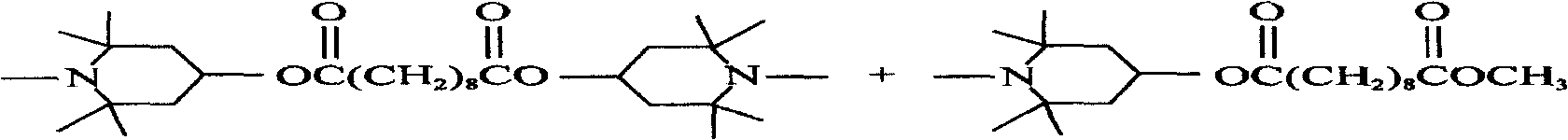

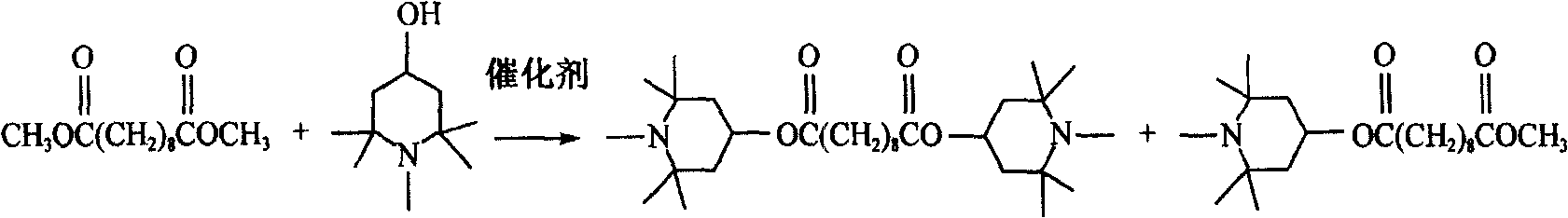

Method used

Image

Examples

Embodiment 1

[0023] Put 225KG of pentamethylpiperidinol and 130KG of dimethyl sebacate into the transesterification reaction kettle, start stirring, pass in an inert gas——nitrogen protection, and then heat up; after the temperature rises to 115-118°C, press the feeding The number of moles is based on 3.5KG of double-effect transesterification catalyst—sodium methoxide and hydrophilic plasticizer, of which 2.5KG of sodium methoxide and 1.0KG of hydrophilic plasticizer are put into the transesterification reactor for reaction, and continue to heat up to 115~118℃ Finally, keep the temperature, control the reaction time for 9.5 hours, and carry out the atmospheric pressure solvent-free transesterification reaction to remove the by-product methanol; the reaction end point is controlled by distilling the weight of the reaction by-product methanol, and the reaction ends after passing the test.

[0024] When the reaction product is cooled to below 60°C, a measured amount of petroleum ether is added...

Embodiment 2

[0027] Other conditions are the same as in Example 1. The transesterification reaction is carried out at a reaction temperature of 165-172° C., and the reaction time is controlled for 6 hours. Finally, the chroma of the finished product is ≥80 Hezen.

Embodiment 3

[0029] Other conditions are the same as in Example 1. The transesterification reaction is carried out at a reaction temperature of 188-195° C., and the reaction time is controlled for 5 hours. Finally, the chroma of the finished product is 100-110 black.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com