Method for preparing bis(1-alkoxy-2,2,6,6-tetramethyl piperidine-4-yl) sebate

A technology of tetramethylpiperidine and tetramethylpiperidinol, applied in bis(1-alkoxy-2,2,6,6-tetramethylpiperidin-4-yl) sebacate In the field of preparation, it can solve the problems of by-products that are difficult to handle, difficult to handle, and pollute the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

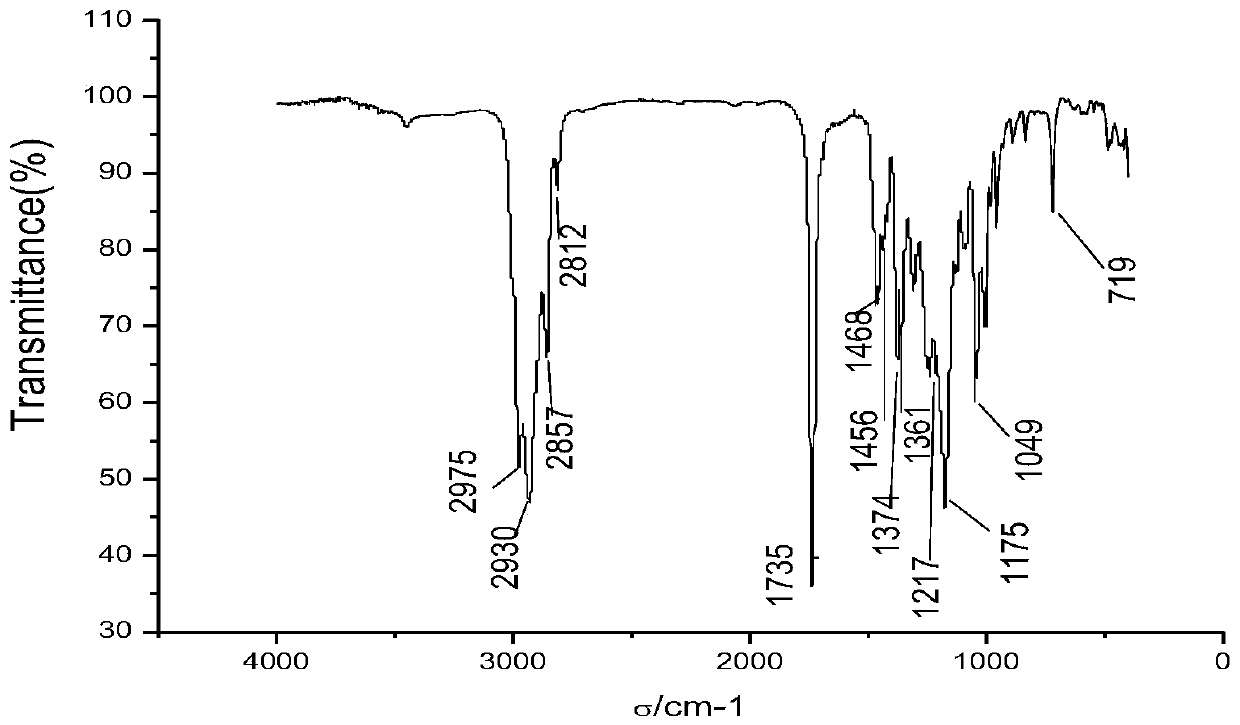

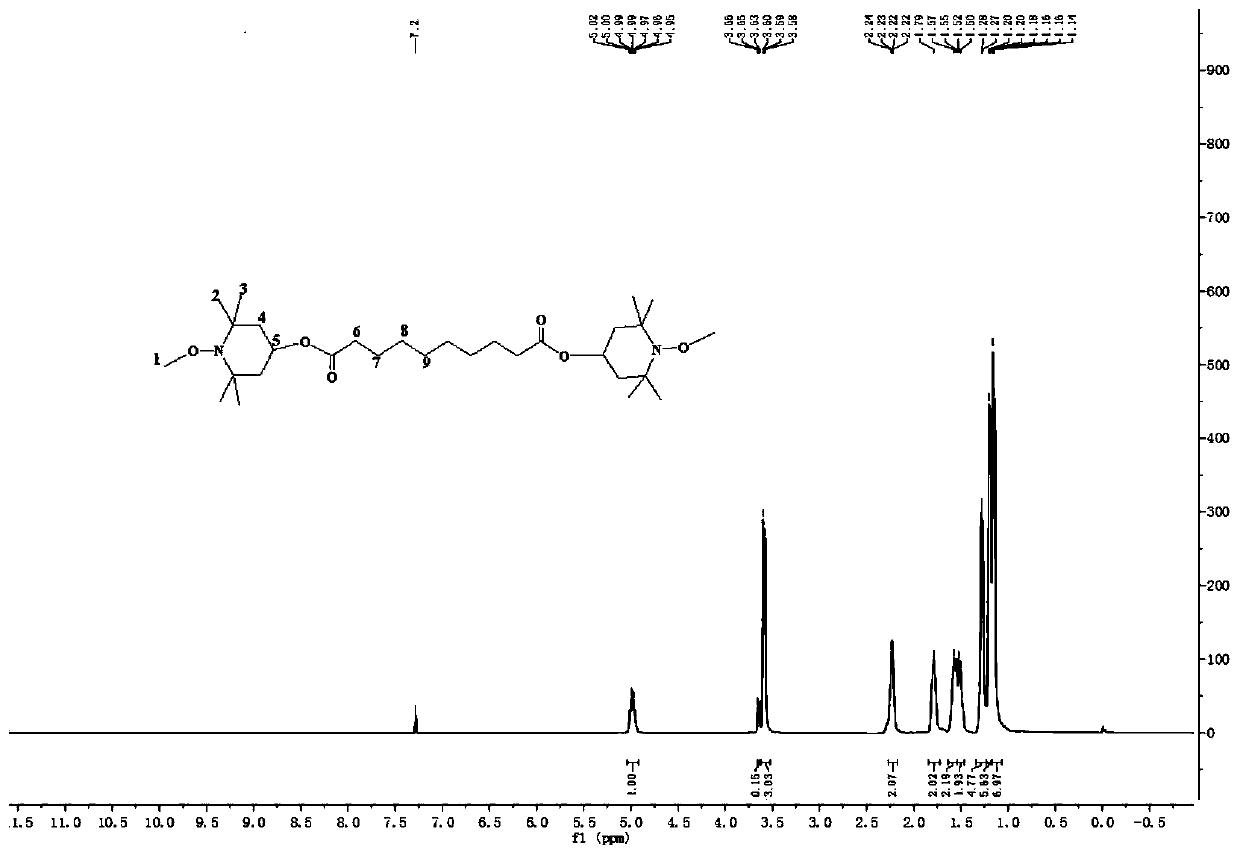

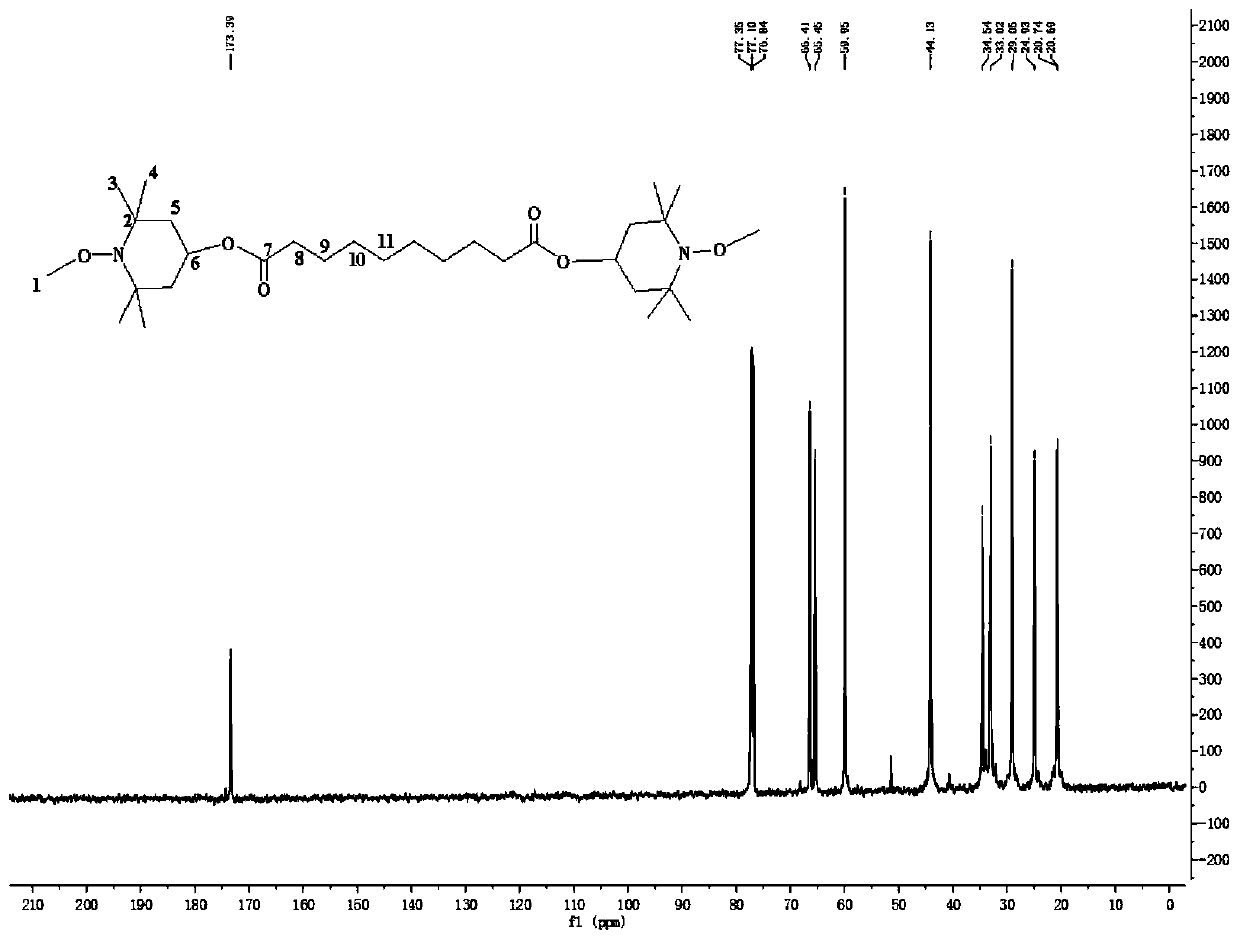

[0059] A preparation method of bis(1-methoxy-2,2,6,6-tetramethylpiperidin-4-yl) sebacate, comprising the steps of:

[0060] (1) Synthesis: 0.11mol (20.60g) of 1-methoxy-4-hydroxyl-2,2,6,6-tetramethylpiperidinol, 0.05mol (11.51g) of dimethyl sebacate and Add 100g of n-heptane into a 250mL three-necked flask with mechanical stirring, water separator and condenser, add ground 0.09mol (2.20g) lithium hydroxide and 0.003mol (1g) tetrabutylammonium bromide, and heat up To the reflux state (about 98°C), the methanol was continuously refluxed to separate, and the reaction was stopped when no methanol was separated after reflux (about 5h).

[0061] (2) Purification: After the reaction, cool down to room temperature, add 40mL×3 deionized water to wash 3 times, distill off the solvent and unreacted 1-methoxy-2,2,6,6-tetramethyl under reduced pressure Piperidinol obtained 27.47g of crude product, added the crude product into 55g m (methanol): m (water) = 0.8:1 mixed solvent, stirred for ...

Embodiment 2

[0070] A preparation method of bis(1-ethoxy-2,2,6,6-tetramethylpiperidin-4-yl) sebacate, comprising the steps of:

[0071] (1) Synthesis: 0.11mol (22.11g) of 1-ethoxy-4-hydroxyl-2,2,6,6-tetramethylpiperidinol, 0.05mol (11.51g) of dimethyl sebacate and Add 100g of n-heptane into a 250mL three-necked flask equipped with a mechanical stirrer, a water separator, and a condenser, and add 0.09mol (2.20g) of lithium hydroxide and 0.003mol (about 1g) of tetrabutylammonium bromide after grinding, Raise the temperature to the reflux state (about 98°C), continuously reflux to separate methanol, and stop the reaction when no methanol is separated after reflux (about 5h).

[0072] (2) Purification: After the reaction, cool down to room temperature, add 40mL×3 deionized water to wash, and distill off the solvent and unreacted 1-ethoxy-2,2,6,6-tetramethylpiperidine under reduced pressure Alcohol yielded 26.95g of the crude product. Add the crude product to 55g of m (methanol): m (water) = 0...

Embodiment 3

[0080] A preparation method of bis(1-propoxy-2,2,6,6-tetramethylpiperidin-4-yl) sebacate, comprising the steps of:

[0081] (1) Synthesis: 0.11mol (23.65g) of 1-propoxy-4-hydroxyl-2,2,6,6-tetramethylpiperidinol, 0.05mol (11.51g) of dimethyl sebacate and 100g of n-heptane was added to a 250mL three-necked flask equipped with a mechanical stirrer, a water separator and a condenser, and 0.09mol (2.20g) of lithium hydroxide and 0.003mol (about 1g) of tetrabutylammonium bromide were added into the ground, Raise the temperature to the reflux state (about 98°C), continuously reflux to separate methanol, and stop the reaction when no methanol is separated after reflux (about 5h).

[0082] (2) Purification: After the reaction, cool down to room temperature, add 40mL×3 deionized water to wash, and distill off the solvent and unreacted 1-propoxy-2,2,6,6-tetramethylpiperidine under reduced pressure The crude product was 30.65g, and the crude product was added to 60g m (methanol): m (wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com