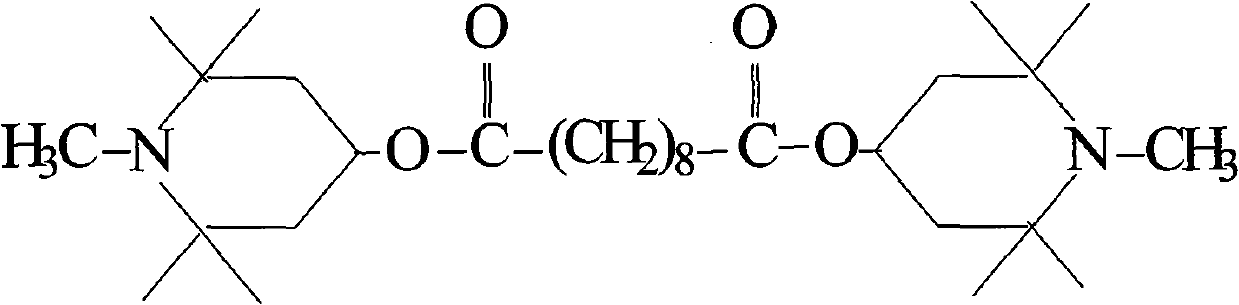

Method for producing light stabilizer sebacic acid (1, 2, 2, 6, 6-pentamethyl-4-piperidyl) diester

A technology of dimethyl sebacate and sebacic acid, which is used in the production field of light stabilizer sebacate bis(1,2,2,6,6-pentamethyl-4-piperidinyl) ester , can solve the problems of large pollution, poor product quality, easy to corrode equipment, etc., to achieve the effect of simplifying the separation and purification process, short reaction time, and small environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In a 250mL four-necked flask equipped with a thermometer, add 40g of petroleum ether, 23.0g of dimethyl sebacate, 35.12g of 1,2,2,6,6-pentamethyl-4-hydroxypiperidine, catalyst 1.2 g, install a condenser, start the agitator, when the temperature rises to 100-120°C, the methanol generated during the reaction is continuously evaporated, and the reaction time is 2h (monitor the reaction by gas chromatography). After the reaction is finished, filter and wash with water, collect the organic phase, remove water, decolorize, and dissolve the organic phase to obtain bis(1,2,2,6,6-pentamethyl-4-piperidinyl) sebacate , the product yield is 97.01%.

Embodiment 2

[0019] In a 250mL four-necked flask equipped with a thermometer, add 40g of petroleum ether, 23.0g of dimethyl sebacate, 50.6g of 1,2,2,6,6-pentamethyl-4-hydroxypiperidine, catalyst 1.2 g, install a condenser, start the agitator, when the temperature rises to 100-120°C, the methanol generated during the reaction is continuously evaporated, and the reaction time is 2h (monitor the reaction by gas chromatography). After the reaction is finished, filter and wash with water, collect the organic phase, remove water, decolorize, and dissolve the organic phase to obtain bis(1,2,2,6,6-pentamethyl-4-piperidinyl) sebacate , the product yield is 98.73%.

Embodiment 3

[0021] In a 250mL four-necked flask equipped with a thermometer, add 40g of petroleum ether, 23.0g of dimethyl sebacate, 36.83g of 1,2,2,6,6-pentamethyl-4-hydroxypiperidine, catalyst 1.2 g, install a condenser, start the agitator, when the temperature rises to 100-120°C, the methanol generated during the reaction is continuously evaporated, and the reaction time is 2h (monitor the reaction by gas chromatography). After the reaction is finished, filter and wash with water, collect the organic phase, remove water, decolorize, and dissolve the organic phase to obtain bis(1,2,2,6,6-pentamethyl-4-piperidinyl) sebacate , the product yield is 97.63%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com