Preparation method of temperature-adjusting texture by in-situ photo-induced polymerization

A kind of technology of ultraviolet light, production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

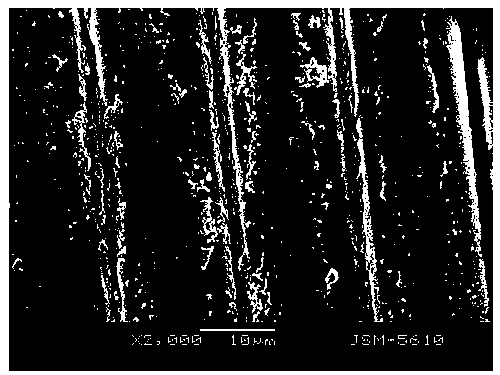

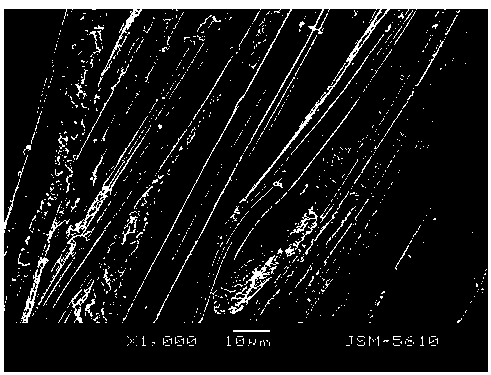

Image

Examples

Embodiment 1

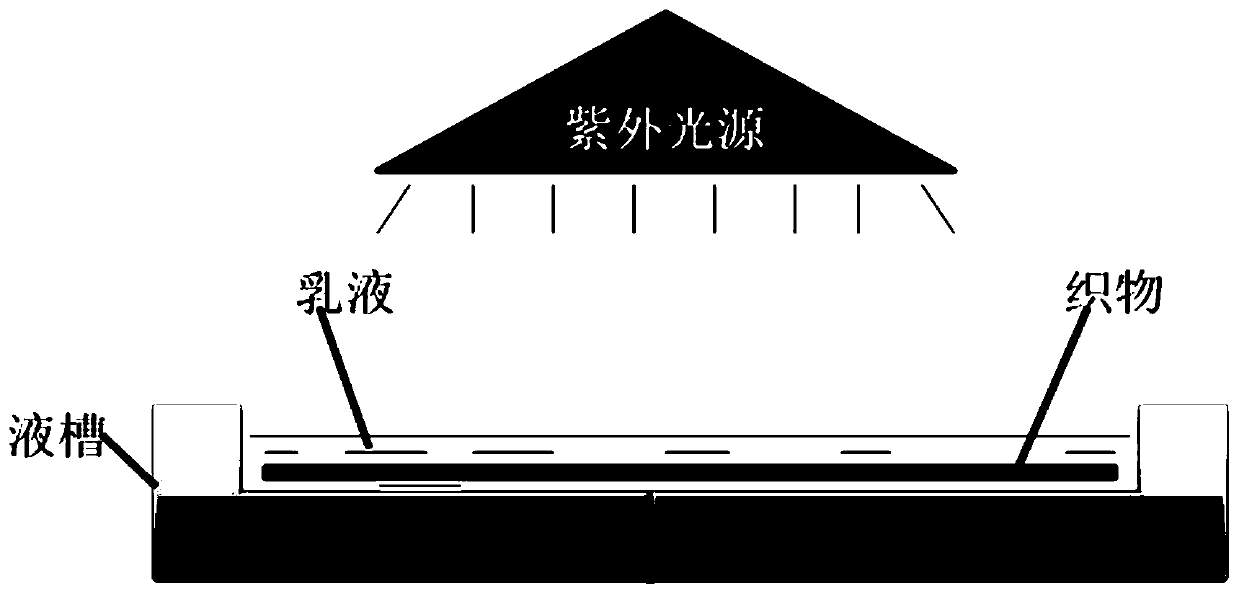

[0031] A method for preparing temperature-adjusting fabrics by in-situ ultraviolet photoinitiated polymerization, comprising the following steps:

[0032] (1) Raw material preparation: The phase change microcapsule emulsion raw materials include the following raw materials in weight fractions, 100 g of paraffin, 80 g of methyl methacrylate, 20 g of ethyl acrylate, 5 g of Tween 20, 2.5 g of Span 80 , 0.1 g cetyltrimethylammonium bromide (CTAB), 1 g azobisisobutyronitrile, 800 g deionized water, a batch of polyester fabric;

[0033] (2) Preparation of oil phase and water phase components: Stir and mix the above oil phase components at 40 °C at 500 r / min to make an oil phase; stir and activate the above mixed emulsifier and deionized water at 40 °C, Prepare the water phase component;

[0034] (3) Raw material emulsification: at a temperature of 40°C, add the oil phase component to the water phase component, and stir and emulsify at a speed of 2500 r / min for 40 minutes to obtain ...

Embodiment 2

[0038] A method for preparing temperature-adjusting fabrics by in-situ ultraviolet light-induced polymerization, comprising the following steps:

[0039] (1) Raw material preparation: The phase change microcapsule emulsion raw materials include the following raw materials in weight fractions, 100 g co-melt of myristyl alcohol and capric acid (mass ratio 2:3), 30 g methyl methacrylate, 20 g ethyl acrylate, 3 g Tween 20, 1.5 g Span 80, 0.1 g sodium lauryl sulfate, 0.5 g azobisisobutyronitrile, 450 g deionized water, a batch of bamboo fiber fabric;

[0040] (2) Preparation of oil phase and water phase components: Stir and mix the above oil phase components at 30 °C at 800 r / min to make an oil phase; stir and activate the above mixed emulsifier and deionized water at 40 °C, Prepare the water phase component;

[0041] (3) Raw material emulsification: at a temperature of 35°C, add the oil phase component to the water phase component, and stir and emulsify at a speed of 10000 r / min fo...

Embodiment 3

[0045] A method for preparing temperature-adjusting fabrics by in-situ ultraviolet photoinitiated polymerization, comprising the following steps:

[0046] (1) Raw material preparation: The phase change microcapsule emulsion raw materials include the following raw materials by weight fraction, 100 g co-melt of myristyl alcohol and lauric acid (mass ratio 45:55), 50 g methyl methacrylate, 30 g ethyl acrylate, 4 g Tween 20, 1.5 g Span 80, 0.5 g sodium lauryl sulfate, 0.8 g azobisisobutyronitrile, 750 g deionized water, a batch of cotton fabric;

[0047] (2) Preparation of oil phase and water phase components: Stir and mix the above oil phase components at 35 °C at 800 r / min to make an oil phase; stir and activate the above mixed emulsifier and deionized water at 38 °C, Prepare the water phase component;

[0048] (3) Raw material emulsification: at a temperature of 35°C, add the oil phase component to the water phase component, and stir and emulsify at a speed of 5000 r / min for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com