Coating finishing technology of intelligent temperature-regulating textile based on phase change microcapsules

A phase change microcapsule and coating finishing technology, applied in textiles and papermaking, etc., can solve the problems of weak bonding fastness, high thermal conductivity, and low bonding rate between phase change microcapsules and fabrics, and is beneficial to industrial production and The effect of promotion, simple production process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]1. raw material preparation: the used fabric of the present invention is the polyester fabric of pretreatment and pre-setting.

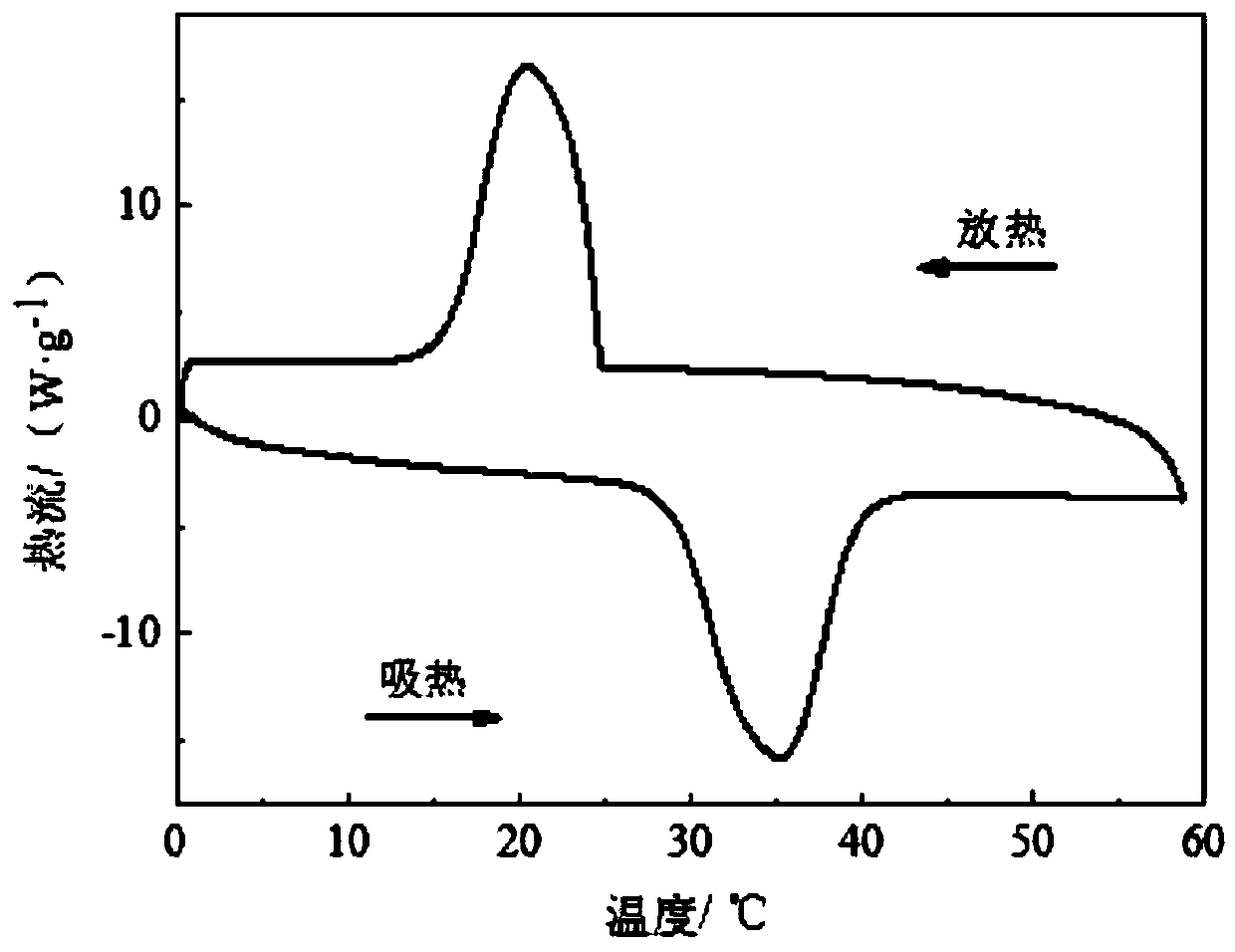

[0042] 2. Preparation of phase-change microcapsules: Mix 250 parts of water and 3 parts of CTAB emulsifier evenly, add 40 parts of core material under high-speed stirring, place in a water bath with a constant temperature of 40°C and heat at a temperature of 10,000r / min. Stir at a rotating speed until a stable O / W emulsion is formed, and then add ammonia water dropwise to adjust the pH to 8.5. Then adjust the rotating speed to 360r / min, add the mixed solution of tetraethyl orthosilicate (20 parts) and ethanol (178 parts) to the emulsion drop by drop, after the addition is completed, adjust the rotating speed to 300r / min, Reaction 24h. Take the microcapsule emulsion that has been reacted, centrifuge and take out the solid to dry to obtain SiO 2 Phase change microcapsule powder.

[0043] 3. Coating finishing process combining phase change micr...

Embodiment 2

[0045] 1. raw material preparation: the used fabric of the present invention is the polyester fabric of pretreatment and pre-setting.

[0046] 2. Preparation of phase-change microcapsules: Mix 255 parts of water and 2.5 parts of CTAB emulsifier evenly, add 35 parts of core material under high-speed stirring, place in a water bath with a constant temperature of 45°C and heat at a temperature of 10,000r / min. Stir at a rotating speed until a stable O / W emulsion is formed, and then add ammonia water dropwise to adjust the pH to 8. Then adjust the rotation speed to 360r / min, drop the prepared mixed solution of tetraethyl orthosilicate (18 parts) and ethanol (165 parts) into the emulsion, after the addition is completed, adjust the rotation speed to 300r / min, and react for 24h . Take the microcapsule emulsion that has been reacted, centrifuge and take out the solid to dry to obtain SiO 2 Phase change microcapsule powder.

[0047] 3. Coating finishing process combining phase chang...

Embodiment 3

[0049] 1. raw material preparation: the used fabric of the present invention is the polyester fabric of pretreatment and pre-setting.

[0050] 2. Preparation of phase-change microcapsules: Mix 265 parts of water and 3 parts of CTAB emulsifier evenly, add 40 parts of core material under high-speed stirring, place in a water bath with a constant temperature of 35°C while heating in a water bath at a temperature of 10,000r / min Stir at a rotating speed until a stable O / W emulsion is formed, and then add ammonia water dropwise to adjust the pH to 9. Then adjust the rotation speed to 360r / min, add the mixed solution of tetraethyl orthosilicate (20 parts) and ethanol (175 parts) dropwise into the emulsion, after the addition is completed, adjust the rotation speed to 300r / min, and react for 24h . Take the microcapsule emulsion that has been reacted, centrifuge and take out the solid to dry to obtain SiO 2 Phase change microcapsule powder.

[0051] 3. Coating finishing process comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com