Cool fabric with relatively high human body infrared permeability, and preparation method thereof

A human body infrared and permeability technology, applied in the field of fabric fabrics, can solve the problems of opacity and low infrared transmittance of cool fabrics, and achieve good temperature regulation, good ventilation and perspiration performance, mechanical properties, and good wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of a cool fabric with higher human body infrared transmittance, comprising the following steps:

[0031] (1) the molecular weight is 3,000,000 high-density polyethylene and decahydronaphthalene are mixed, and the weight ratio of polyethylene and decahydronaphthalene is 1:3, forms mixture;

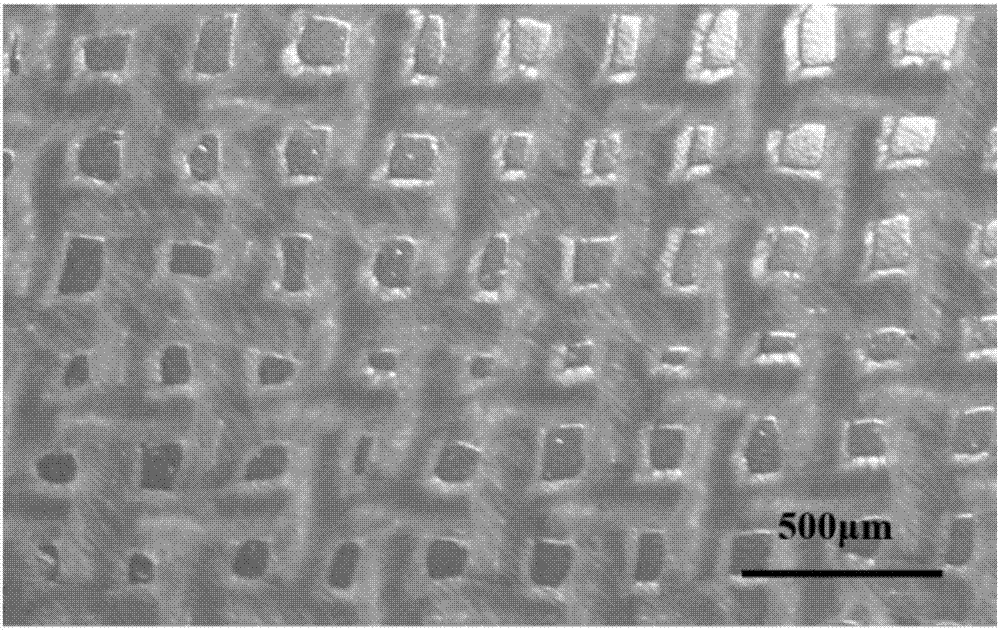

[0032] (2) After the mixture is melted by a twin-screw extruder, it is coated on the surface of the polyester plain woven fabric. The coating is single-sided coating, the thickness of the coating is 10 μm, the melting temperature is 160 ° C, and the time is 15 minutes. The thickness of the polyester plain woven fabric is 60μm, the yarn count is 30D, and the fabric weight is 30g / m 2 ;

[0033] (3) Press the polyester plain woven fabric coated with the molten mixture for 3 minutes at a temperature of 140°C and a pressure of 0.2MPa, and then place it in cold water at about 5°C to cool;

[0034] (4) Use absolute ethanol to extract and remove decahydronaphthalene, t...

Embodiment 2

[0060] A preparation method of a cool fabric with higher human body infrared transmittance, comprising the following steps:

[0061] (1) mixing high-density polyethylene with a molecular weight of 2 million and white oil, the weight ratio of high-density polyethylene and white oil is 1:11.5 to form a mixture;

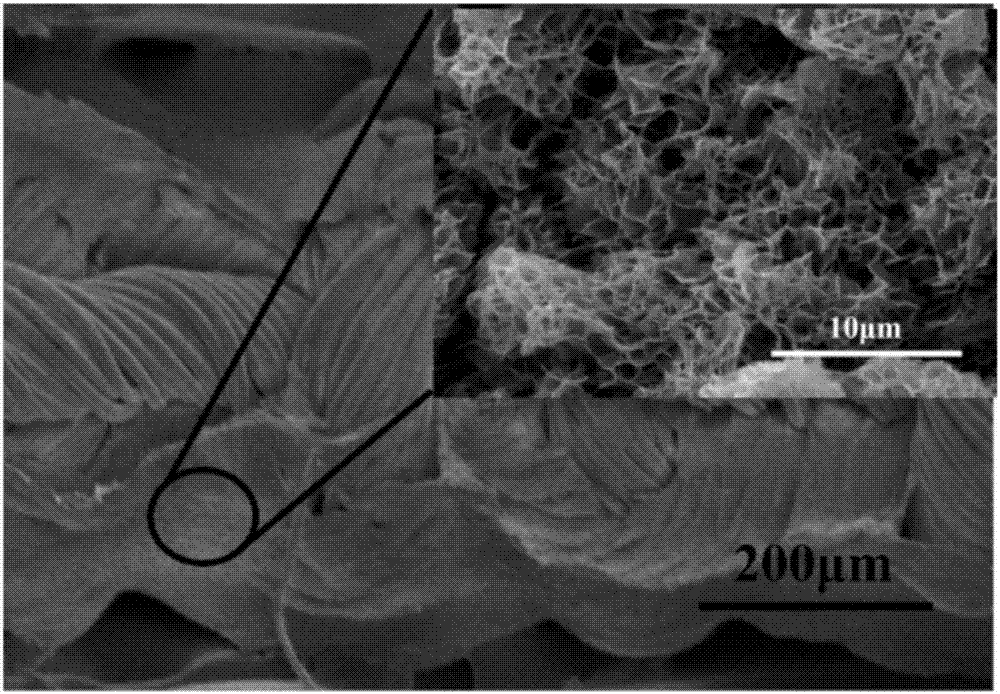

[0062] (2) Melt the mixture with a blender and apply it to the surface of the polyester-cotton plain woven fabric. The coating is double-sided coating, the thickness of the coating is 20 μm, the melting temperature is 155 ° C, and the time is 20 minutes. The thickness of cotton plain woven fabric is 120μm, the yarn count is 100D, and the fabric weight is 80g / m 2 ;

[0063] (3) Press the polyester-cotton plain woven fabric coated with the molten mixture for 5 minutes at a temperature of 170°C and a pressure of 0.8MPa, and then place it in cold water at about 0°C to cool;

[0064] (4) Use xylene to extract and remove white oil, after washing, dry and shape at 40°C for 2...

Embodiment 3

[0090] A preparation method of a cool fabric with higher human body infrared transmittance, comprising the following steps:

[0091] (1) Mix high-density polyethylene with a molecular weight of 100,000 and diluent (a mixture of decahydronaphthalene and white oil with a volume ratio of 1:1), and the weight ratio of high-density polyethylene to diluent is 1:5, form a mixture;

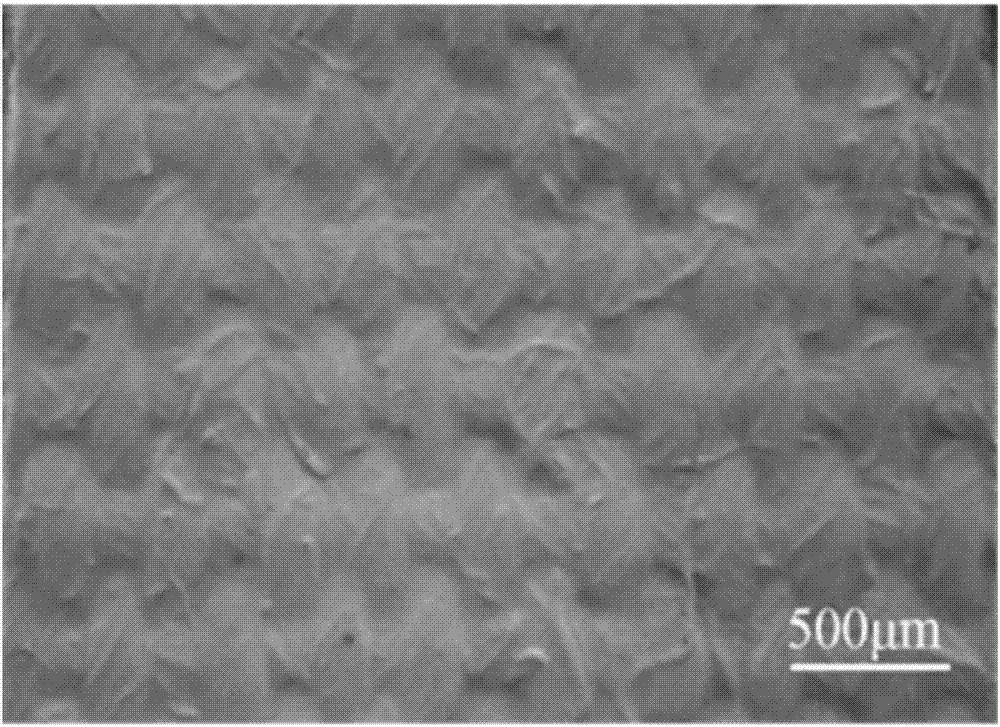

[0092] (2) Melt the mixture with a blender and apply it to the surface of nylon plain woven fabric. The coating is double-sided coating, the thickness of the coating is 35 μm, the melting temperature is 170 ° C, and the time is 20 minutes. Nylon plain weave The thickness of the woven fabric is 70μm, the yarn count is 80D, and the fabric weight is 40g / m 2 ;

[0093] (3) Press the nylon plain woven fabric coated with the molten mixture for 6 minutes at a temperature of 158°C and a pressure of 0.28MPa, and then place it in cold water at about 2°C to cool;

[0094] (4) Use chloroform to extract and remove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yarn count | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com