A kind of preparation method of knitted fabric with adjustable temperature

A technology for knitted fabrics and temperature regulation, applied in the field of knitted fabrics, can solve problems such as the inability to meet the requirements of clothing comfort performance, and achieve the effects of improving temperature regulation effect, improving contact efficiency, and improving uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0048] The preparation method of phase change microcapsules comprises the following steps:

[0049] Step a: the paraffin wax and the emulsifier with a mass ratio of 1:2 are stirred at 35° C. for 20 min with a rotating speed of 1500 r / min to obtain a paraffin wax emulsion;

[0050] Step b: adding 50 parts by weight of sodium alginate to 200 parts by weight of distilled water, and dissolving at 50° C. and stirring evenly to obtain a pale yellow sodium alginate solution;

[0051] Step c: adding 30 parts by weight of anhydrous calcium chloride to 500 parts by weight of distilled water, dissolving and stirring evenly to obtain a solidified phase;

[0052] Step d: adding the paraffin wax emulsion to the sodium alginate solution, and stirring for 30 minutes at a rotating speed of 1000 r / min to obtain a preliminary emulsion;

[0053] Step e: adding the prepared emulsion dropwise into the solidified phase at a rate of 30 drops / min, so that the sodium alginate is solidified to obtain m...

Embodiment 1

[0057] A preparation method of a knitted fabric with adjustable temperature, comprising the following steps:

[0058] Yarn pretreatment: A1: Use concentrated sulfuric acid and deionized water to prepare a sulfuric acid solution with a mass concentration of 0.1%, for use;

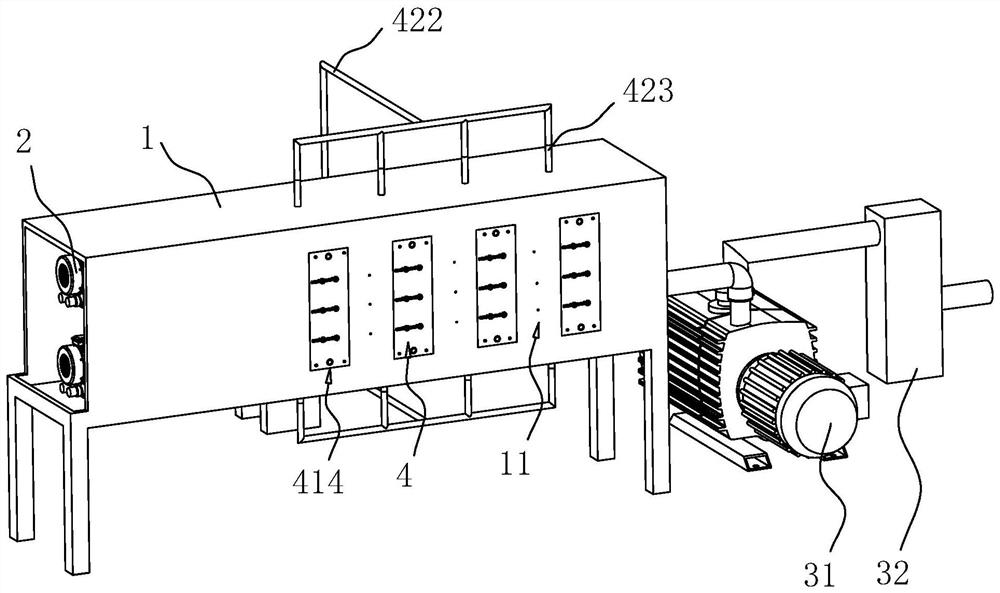

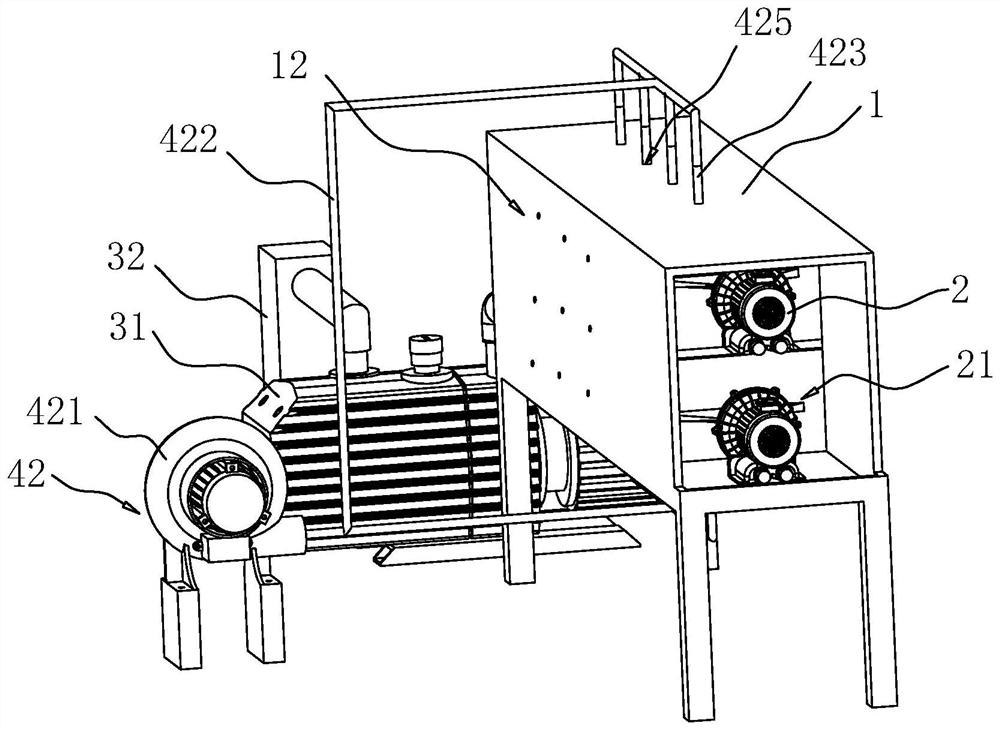

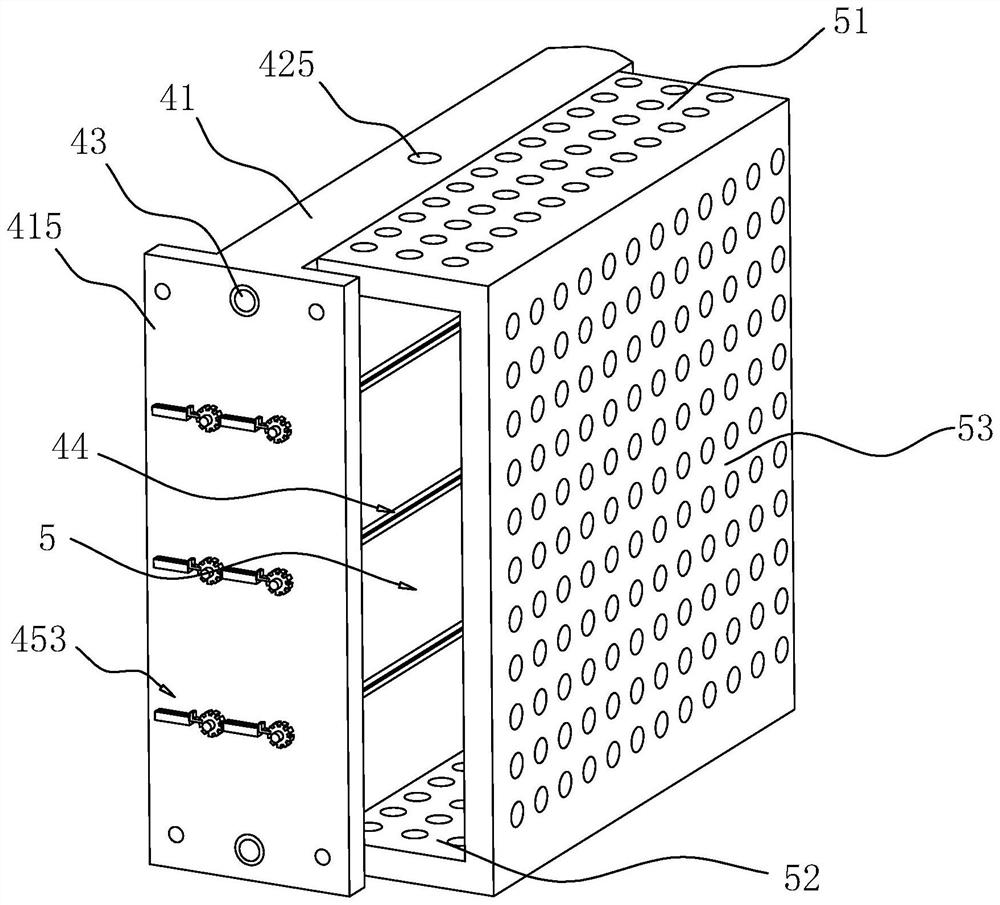

[0059] A2: The sulfuric acid solution is passed into the atomization chamber for atomization, and the yarn used for weaving knitted fabrics is passed through the atomization chamber. The speed of the yarn passing through the atomization chamber is 4m / s, and the liquid input volume in the atomization chamber is 5L. / 2h;

[0060] A3: The yarn after passing through the atomization chamber is passed into the drying oven for drying. The drying temperature in the drying oven is controlled at 70°C, and the drying time of the yarn in the drying oven is controlled at 8 minutes. .

[0061] Yarn weaving:

[0062] S1: Pass the pre-treated yarn into the treatment tank containing phase change microcapsules, soaking tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com