Blended yarn of air-conditioning fiber and cotton fiber/cotton-type chemical fiber and spinning method

A technology for air-conditioning fibers and chemical fibers, which is applied in the directions of yarn, textiles and papermaking, can solve the problems of air-conditioning fibers failing to exert the temperature-adjusting function, damage of air-conditioning fiber microcapsules, and affecting the temperature-adjusting effect, etc. Temperature regulation effect, good evenness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

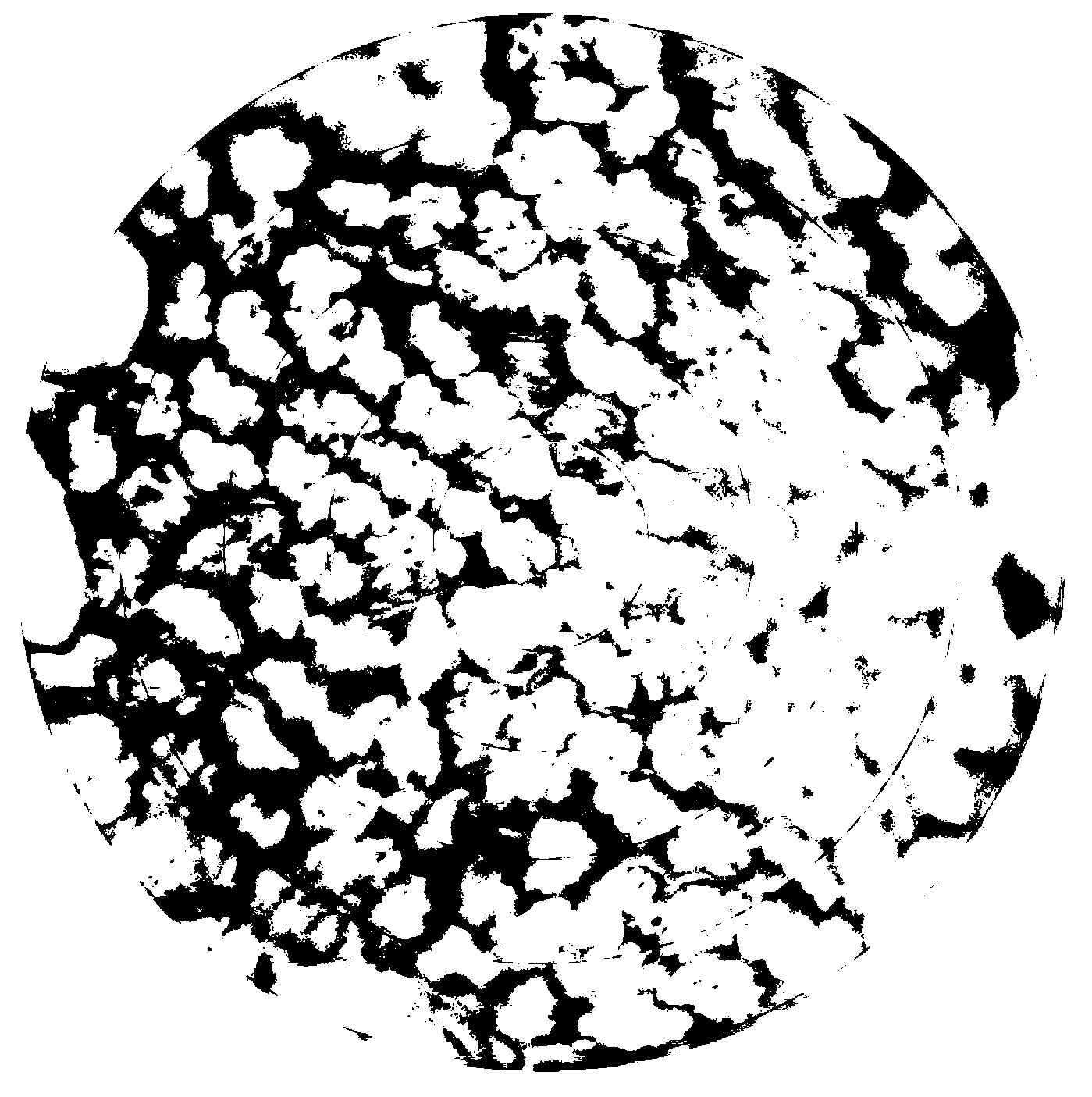

Image

Examples

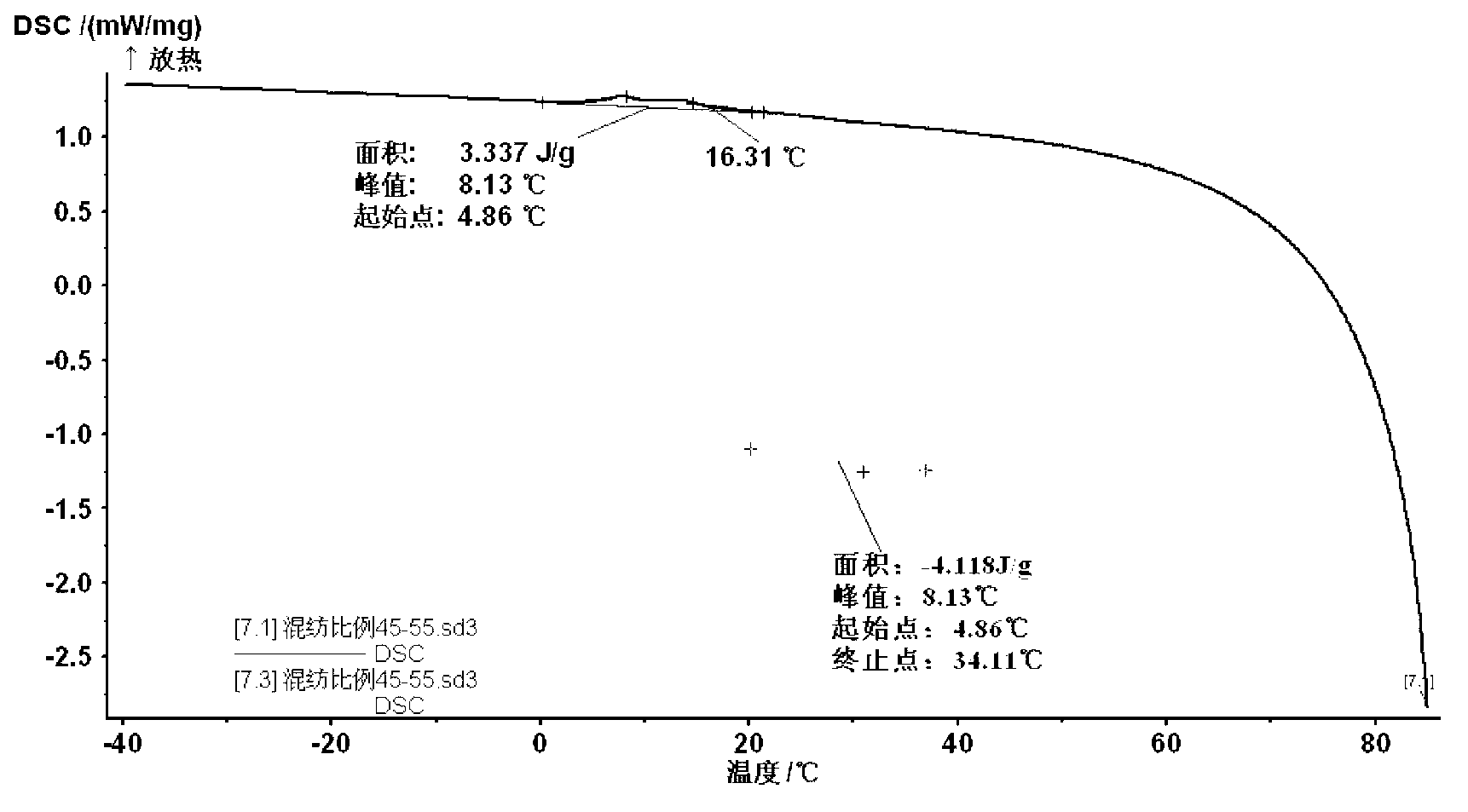

Embodiment 1

[0082] Raw materials used:

[0083] Viscose fiber 1.2D×38mm;

[0084] Air conditioner fiber 1.7D×38mm;

[0085] Mixing ratio: air-conditioning fiber: viscose fiber is 45:55;

[0086] Yarn twist factor: 512;

[0087] Yarn count: 18.4Tex (32S);

[0088] Air-conditioning fibers and viscose fibers are respectively 45:55 according to the mass percentage, the air-conditioning fibers and viscose fibers taken by weighing are respectively processed through opening and cleaning, carding into slivers successively, and output air-conditioning fiber raw slivers and viscose fiber raw slivers respectively, Among them, the air-conditioning fiber raw sliver specification is 21.00g / 5m, and the viscose fiber specification is 18.87g / 5m;

[0089] The air-conditioning fiber raw slivers and viscose fiber raw slivers obtained are sent to the drawing frame respectively, and the air-conditioning fiber raw slivers and viscose fiber raw slivers are respectively drawn by the drawing frame to prepare t...

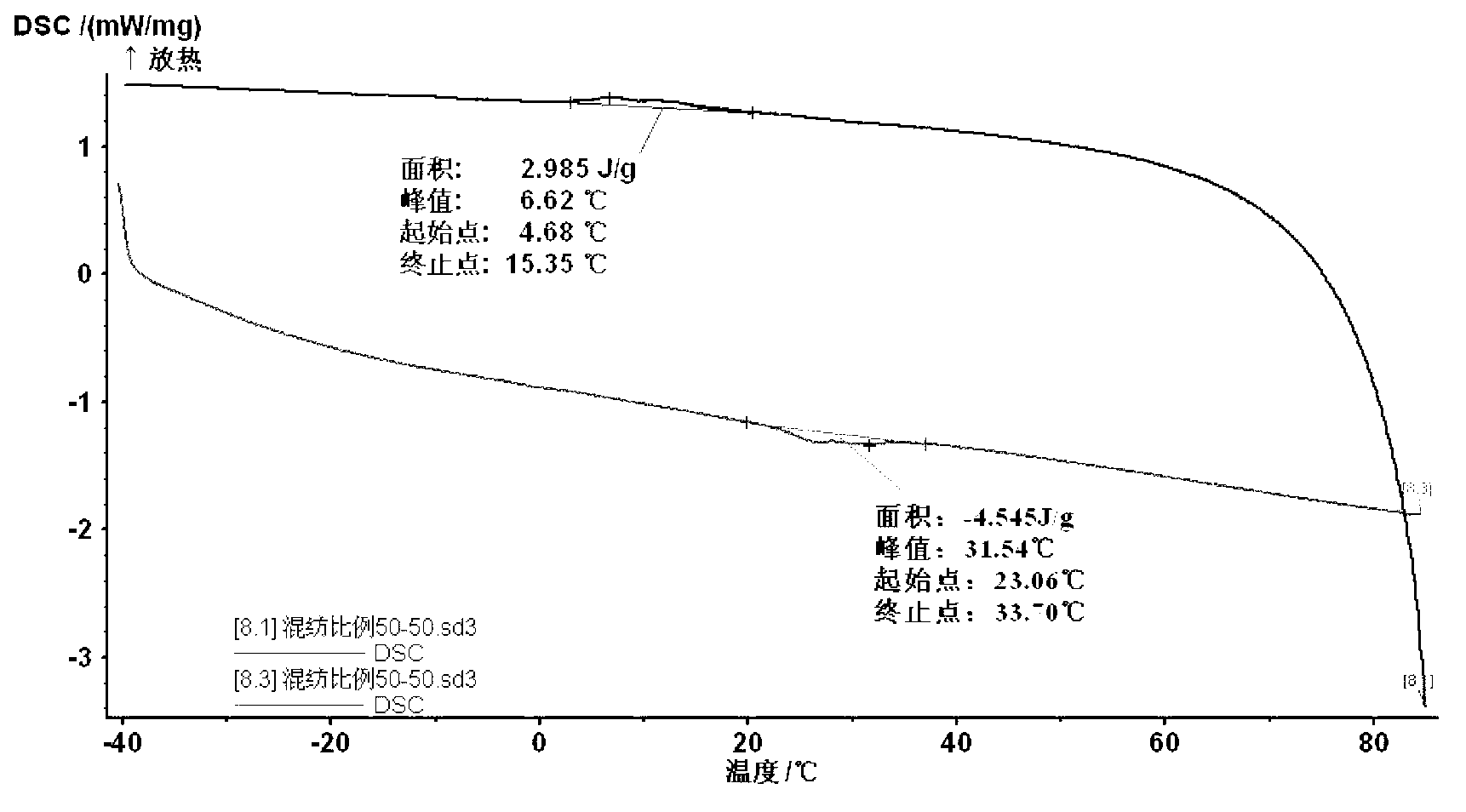

Embodiment 2

[0115] Raw materials used:

[0116]Cotton fiber (13μm~15μm)×(33mm~46mm);

[0117] Air conditioner fiber 1.7D×38mm;

[0118] Mixing ratio: air-conditioning fiber: cotton fiber is 60:40;

[0119] Yarn twist factor: 516;

[0120] Yarn count: 14.75Tex (40 S ).

[0121] Air-conditioning fiber and cotton fiber are respectively 60:40 according to the mass percentage, and the air-conditioning fiber and cotton fiber that weighs are processed successively through opening and cleaning, combing into slivers respectively, and output air-conditioning fiber raw sliver and viscose fiber raw sliver respectively, wherein air-conditioning fiber Fiber 16.65g / 5m, cotton fiber 18.50g / 5m;

[0122] The obtained air-conditioning fiber raw slivers and cotton fiber raw slivers are sent to the drawing frame respectively, and the air-conditioning fiber raw slivers and the cotton fiber raw slivers are respectively subjected to two drawing processes by the drawing frame to prepare cooked air-conditioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com