High-resilience ultralight insole and preparation method thereof

A high-resilience, insole technology, applied in insoles, chemical instruments and methods, footwear, etc., can solve the problems of hot feet, easy to cold feet, reduce consumer comfort, etc., to extend service life, reduce The effect of cleaning times, good antifouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

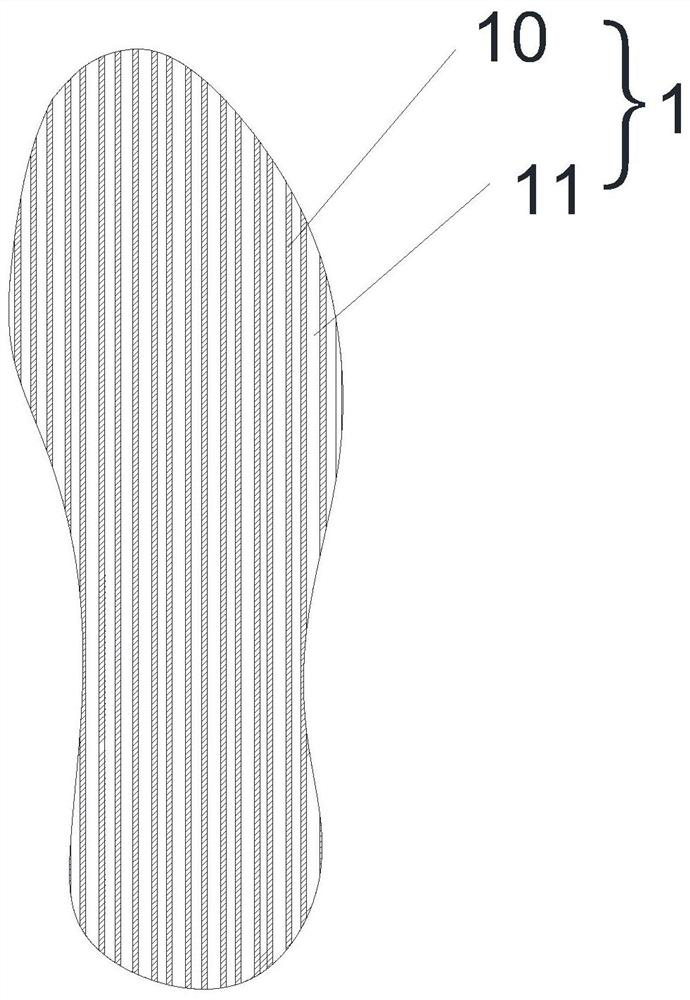

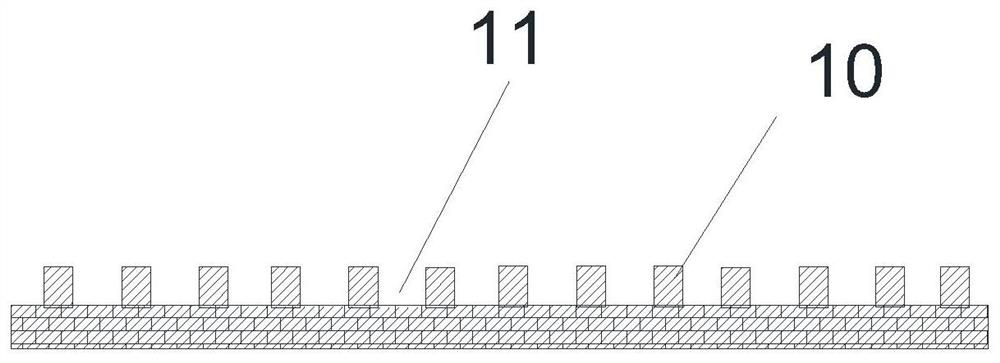

[0042] This embodiment provides a kind of high resilience ultra-light insole, such as figure 1 and figure 2 As shown, it includes a fabric layer 1 and a polyurethane layer 2. The upper surface of the fabric layer 1 is a concave-convex strip structure, including strip-shaped protrusions 10 and strip-shaped depressions 11 that are periodically arranged at intervals, wherein the strip-shaped protrusions 10 is woven with anti-fouling yarn, the width of a single strip-shaped raised portion 10 is 0.5-1.5 mm, and the total area of the strip-shaped raised portion 10 does not exceed 30% of the area of the fabric layer 1; the strip-shaped depressed portion 11 is Woven by temperature-regulating yarn, the width range of a single strip-shaped concave portion 11 is 0.8-2mm; , the strip-shaped convex portion 10 is in contact with the sole of the human body to play an anti-fouling effect, and the strip-shaped concave portion 11 accounts for a large proportion, which can ensure the overa...

Embodiment 2

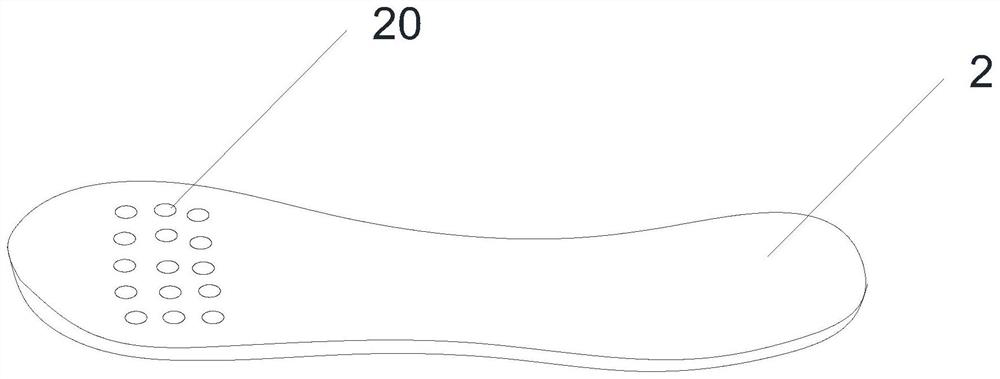

[0047] In order to further increase the wearing comfort of the insole, the present embodiment increases the massage function of the insole on the basis of embodiment 1, such as image 3 As shown, the upper surface of the insole is provided with a circular protrusion 20, which is integrally formed with the polyurethane layer 2. Its diameter is 0.5-1cm, and its height is 0.5-0.8cm. The circular protrusion 20 The position corresponds to the position of the forefoot or the acupuncture point of the foot to play a massage effect; at this time, the fabric layer 10 can have two kinds of settings, one is that the position of the fabric layer 10 corresponding to the circular protrusion 20 is a hole, and the hole is used In order to accommodate these circular protrusions 20, the surface of the circular protrusions is separately covered with a layer of fabric of the same material as the fabric layer 10, so that the surface layer in contact with the sole of the foot is all fabric layers; an...

Embodiment 3

[0049] This embodiment, as a modification of Embodiment 2, is another insole with a massage function. The massage method is carried out through flowing liquid, and it is used for soothing massage when the feet are in motion. Its structure is as follows: Figure 4 As shown, the side where the polyurethane layer 2 is attached to the fabric layer 1 is provided with circular recesses 21 with a diameter of 0.5-1 cm, and grooves 22 are arranged between each adjacent circular recesses 21, and the top of the circular recesses 21 is bonded to its diameter. Matching adjustable protrusions 23 with a height of 0.5-0.8 cm, the upper part of the groove 22 is provided with an adjustable pipeline 24, the adjustable pipeline 24 is connected to the adjacent adjustable protrusions 23, the adjustable protrusions 23 and The adjustable pipelines 24 each include an elastic shell and a flowing liquid built into the elastic shell, and the liquid adjacent to each adjustable protrusion 23 can flow throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com