Elastic phase change energy storage polyurethane fiber and preparation method thereof

A polyurethane fiber and elastic polyurethane technology, applied in the field of elastic phase change energy storage polyurethane fiber and its preparation, can solve the problems of phase change material leakage, high load rate, etc., and achieve high phase change enthalpy, good flexibility, and good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 (do not add ionic liquid)

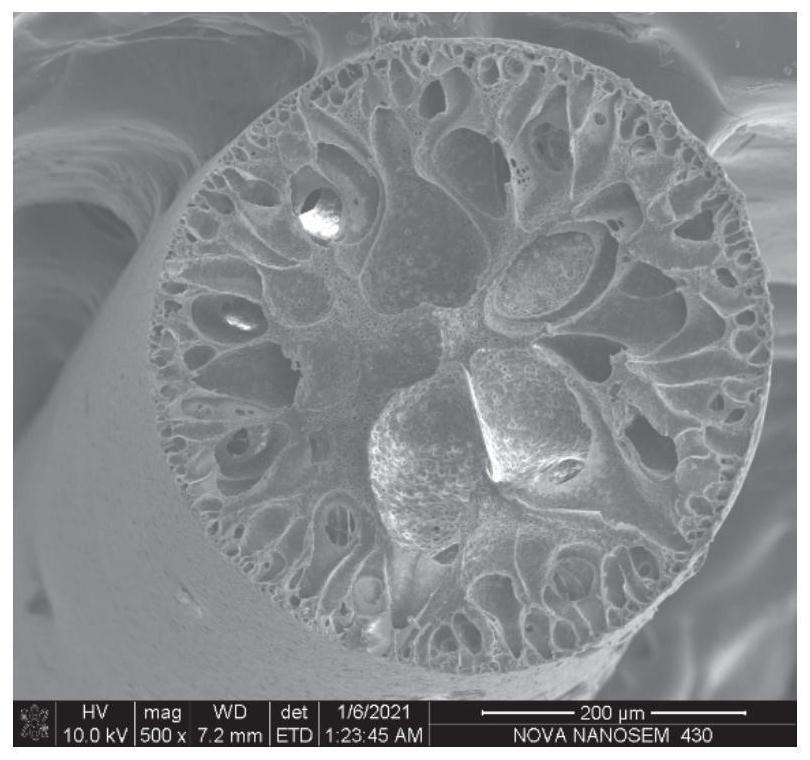

[0054] (1) Take 5g of BASF's model 1185A thermoplastic polyurethane and add it to 25ml of N,N-dimethylformamide, stir to obtain a spinning solution, and naturally spin it into the coagulation bath deionized water at room temperature by wet spinning , solidified for 2 minutes to obtain polyurethane fibers; soak the polyurethane fibers in deionized water for 8 hours; freeze the fibers at -100°C for 5 hours, and then place the fibers on the board in the freeze dryer at an absolute pressure of 5Pa, freeze-drying for 12 hours at a temperature of 30° C. to obtain porous polyurethane fibers;

[0055] (2) Soak the porous polyurethane fiber completely in molten octadecane (heat and melt the octadecane), place it in a vacuum environment at 50°C for 10h, and hang the porous polyurethane fiber loaded with octadecane in the air at 50°C Stand still in the environment for 5 hours to remove excess octadecane on the surface to obtain octadecane / ...

Embodiment 2

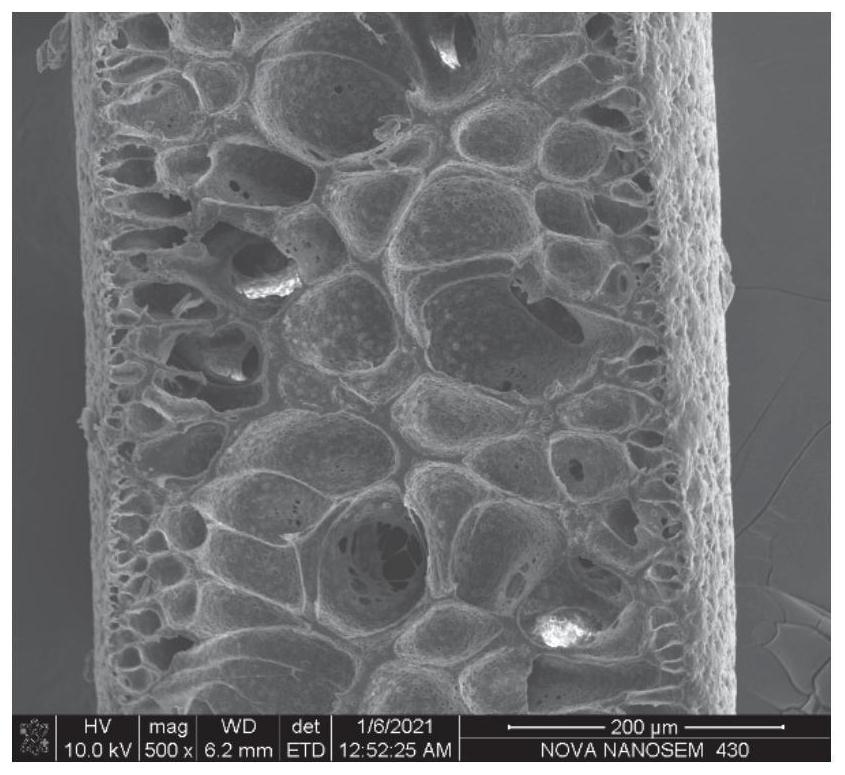

[0059] (1) Take 3g of 1-decyl-3-methylimidazolium bromide and add it to 25ml of N,N-dimethylformamide, stir to obtain a mixed solution; then take 7g of BASF model 685A thermoplastic polyurethane and add it to the mixed solution In the process, the spinning solution was prepared; the aqueous solution of 30wt% N,N-dimethylformamide was used as a coagulation bath to carry out wet spinning at room temperature, and solidified for 4min to obtain polyurethane fibers; the polyurethane fibers were soaked in deionized water for 8h , the fibers were frozen at -120°C for 8 hours, and then the fibers were placed on the inner plate of the freeze dryer, and then freeze-dried for 18 hours under the conditions of an absolute pressure of 10Pa and a plate temperature of 35°C to obtain porous polyurethane fibers;

[0060] (2) Soak the porous polyurethane fiber in molten cetyl alcohol, place it in a vacuum environment of 70°C for 10h, hang the porous polyurethane fiber loaded with cetyl alcohol in ...

Embodiment 3

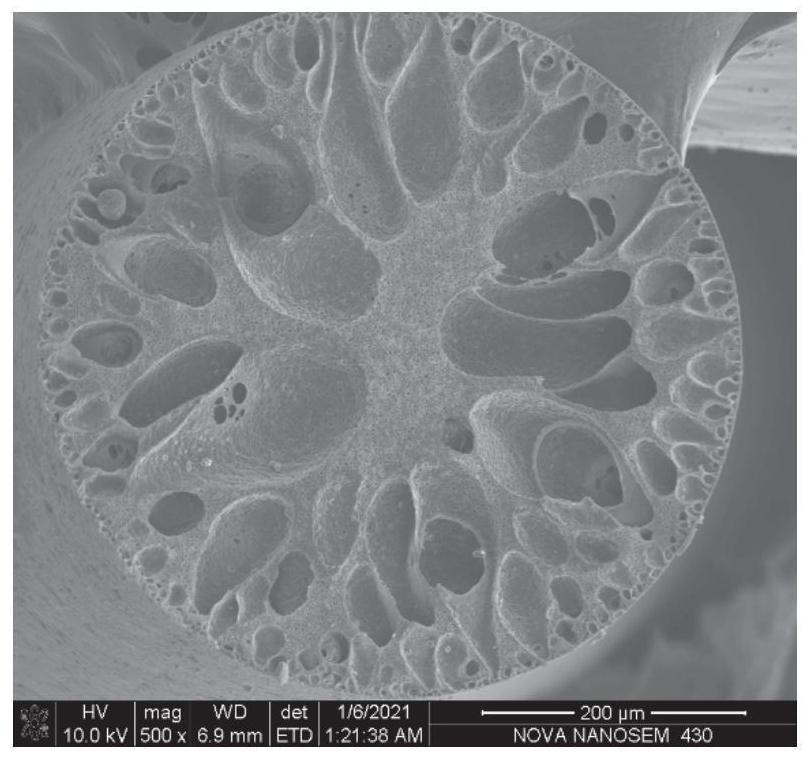

[0064] (1) Add 5g of 1-butyl-3-methylimidazolium hexafluorophosphate to 25ml of acetone and stir to obtain a mixed solution; then take 10g of BASF’s model b95a thermoplastic polyurethane and add it to the mixed solution to obtain a spinning solution ; Use 10% N,N-dimethylformamide aqueous solution as a coagulation bath to carry out wet spinning at 40 ° C, solidify for 3 minutes, and obtain polyurethane fibers; polyurethane fibers are soaked in deionized water for 6 hours, and then the fibers are placed in Freeze at -150°C for 3 hours, then place the fibers on the inner plate of the freeze dryer, freeze-dry for 15 hours at an absolute pressure of 15Pa, and a plate temperature of 45°C to obtain porous polyurethane fibers;

[0065] (2) Soak the porous polyurethane fiber in molten stearic acid, place it in a vacuum environment of 100°C for 12h, hang the porous polyurethane fiber loaded with stearic acid in an environment of 100°C and let it stand for 8h, remove excess surface Stea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com