Ceramic digital glaze ink with sterilization and far infrared composite functions and preparation method thereof

A composite function, far-infrared technology, applied in the field of architectural ceramic decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

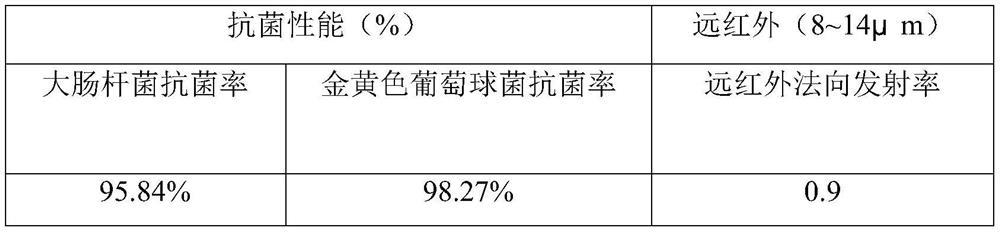

Image

Examples

preparation example Construction

[0033] The preparation process of the digital glaze powder can be as follows: (1) Weigh the Wulan citrine, the high-temperature ceramic frit and the low-temperature ceramic frit according to the mass ratio, and mix the above-mentioned raw materials. Preferably, the sieve residue of the raw material after passing through a 100-mesh sieve is not more than 0.5 wt%. In addition, the moisture content of the raw material is not more than 1.0 wt%. The equipment for mixing the raw materials can be a ball mill or a coulter mixer. Then, the temperature is kept at 800 to 1300° C. for 0.5 to 2.5 hours for firing and homogenization. The purpose of the firing and homogenizing treatment is to facilitate the uniform control of the subsequent ink particle size, thereby ensuring the stability of ink storage. (2) The raw materials of the digital glaze powder are homogenized and then subjected to micro-nano refining treatment. Specifically, the raw material after the firing and homogenization ...

Embodiment 1

[0045] The preparation method of ceramic digital glaze ink includes the following steps:

[0046] Step (1) prepare digital glaze powder. The raw material composition of digital glaze powder includes: 60% of Wulan citrine, 30% of high-temperature ceramic frit, and 10% of low-temperature ceramic frit. The chemical composition of the high temperature ceramic frit includes: in mass percent, SiO 2 48.8%, Al 2 O 3 21.8% Fe 2 O 3 0.5%, TiO 2 0.4%, CaO 16.2%, MgO 3.8%, K 2 O3%, Na 2 O 3%, ZnO 2.5%. The chemical composition of the low temperature ceramic frit includes: in mass percent, SiO 2 62.0%, Al 2 O 3 6.0%, CaO 20%, MgO 4.0%, K 2 O 3%, Na 2 O 3%, ZnO 2%. Weigh Wulan citrine, high-temperature ceramic frit and low-temperature ceramic frit according to the mass ratio, and mix the above-mentioned raw materials. After mixing, the mixture was kept at 1000°C for 2h and fired for homogenization. The raw material after firing and homogenizing treatment is processed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com