A kind of graphene modified color paste, preparation method and application thereof

A graphene modification and graphene technology, applied in the field of dyes, can solve the problems of uneven dispersion of graphene, inability to exert effects, and inability to exert graphene efficacy well, achieving excellent far-infrared performance, easy industrial production, The effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

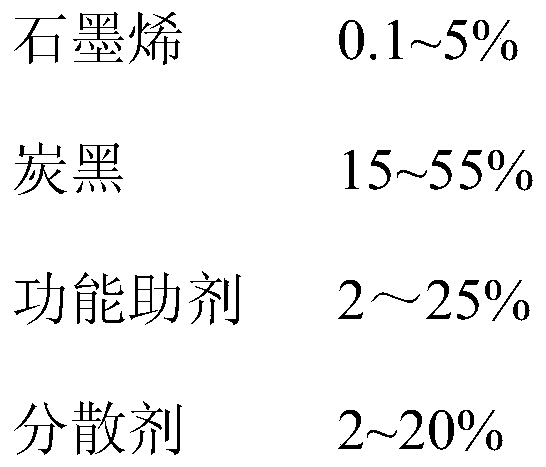

[0053] A kind of graphene modified color paste, it comprises the following components by the weight percentage that each component accounts for:

[0054]

[0055] pH regulator

[0056] The balance is DMF.

[0057] The particle size of the carbon black is 3 μm, the functional additive is a carpine antifungal bactericide, the dispersant is polyacrylate, and the pH regulator is added to adjust the pH of the color paste to 7.

[0058] The preparation method of graphene modified color paste as above may further comprise the steps:

[0059] ①Put the solvent and dispersant into the mixer, and disperse at a speed of 500-700r / min for 15 minutes to obtain the first mixed solution;

[0060] ②Add the functional additive into the first mixed solution and mix evenly to obtain the second mixed solution;

[0061] ③ graphene and carbon black are added to the second mixed solution to obtain a carbon black pre-dispersed slurry;

[0062] ④ Disperse the carbon black pre-dispersed slurry at ...

Embodiment 2

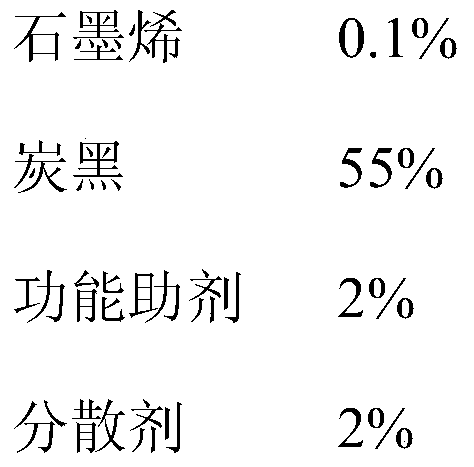

[0068] A kind of graphene modified color paste, it comprises the following components by the weight percentage that each component accounts for:

[0069]

[0070] pH regulator

[0071] The balance is DMF.

[0072] The particle size of the carbon black is 4 μm, the functional auxiliary agent is cellulose ether, the dispersant is polyoxyethylene ether, and the added amount of the pH regulator is to adjust the pH of the color paste to 11.

[0073] The preparation method is the same as in Example 1, except that a pH regulator is slowly added during the dispersion process to control the pH at 11.

[0074] The above-mentioned graphene modified color paste is mixed with the spinning liquid during the spinning process, and the spinning is carried out to obtain colored textiles.

[0075] The far-infrared performance test result is: the normal emissivity is 0.9, and the antibacterial and antibacterial performance test result is: the antibacterial and antibacterial rate for Escheric...

Embodiment 3

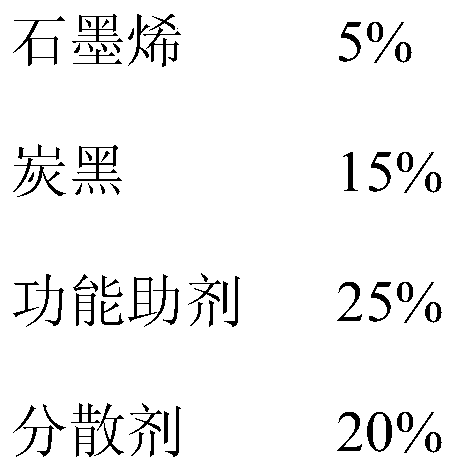

[0077] A kind of graphene modified color paste, it comprises the following components by the weight percentage that each component accounts for:

[0078]

[0079]

[0080] pH regulator

[0081] The balance is water.

[0082] The particle diameter of carbon black is 3 μ m, and functional auxiliary agent is dodecyl dimethyl benzyl ammonium chloride, and dispersant is benzyl naphthalene sulfonate formaldehyde condensate, and the addition amount of pH adjuster is to adjust color paste pH to be 7.

[0083] The preparation method is the same as in Example 1.

[0084] The above-mentioned graphene modified color paste is mixed with the spinning liquid during the spinning process, and the spinning is carried out to obtain colored textiles.

[0085] The far-infrared performance test result is: the normal emissivity is 0.89, and the antibacterial and antibacterial performance test result is: the antibacterial and antibacterial rate against Escherichia coli and Staphylococcus aur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com