Modified acrylic fibre product, as well as preparation method and application thereof

A technology of modified acrylic fibers and fiber products, applied in fiber processing, fiber types, textiles and papermaking, etc., can solve the problems of poor comfort, serious pollution, rough fabric feel, etc., to increase uniformity and firmness, enhance far-infrared performance, to achieve uniform distribution of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0063] A kind of modified acrylic fiber, concrete steps comprise:

[0064] (1) prepare the first graphene dispersion, the particle diameter of graphene in the first graphene dispersion is less than 1 μm; prepare the second graphene dispersion, the particle diameter of graphene in the second graphene dispersion Between 1 and 2 μm;

[0065] (2) the fiber is immersed in the first graphene dispersion at the first temperature, then take out the acrylic fiber impregnated with the first graphene, and continue to immerse it in the second graphene dispersion for 30min, then take it out, dry, Acrylic modified fiber is obtained.

[0066] Performance test: The obtained modified fiber is tested according to GB / T 14342-2015; after that, the modified fiber is washed 50 times, and the washed modified fiber is continued according to GB / T 14342-2015 detection.

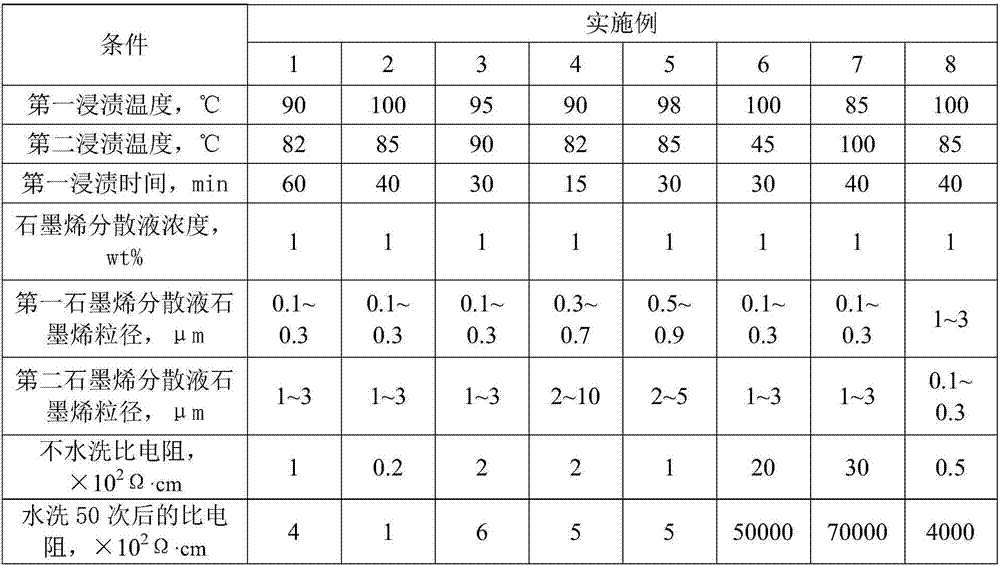

[0067] Table 1 shows the process conditions of Examples 1-8 and the test results of the obtained modified fibers.

[0068] Table 1...

Embodiment 9~12

[0072] A modified fiber, the difference from Example 3 is that nanocellulose (aspect ratio 80~120, diameter below 10nm) is dispersed simultaneously in the first graphene dispersion described in step (2), and the nanocellulose The concentration in the dispersion liquid is 0.1wt% (Example 9), 0.5wt% (Example 10), 1wt% (Example 11), 2wt% (Example 12).

[0073] Using the same performance test method as in Example 3, the test results are shown in Table 2.

Embodiment 13

[0075] A modified fiber, the difference from Example 3 is that the first and second graphene dispersions are replaced by graphene oxide dispersions, and the reduction step is carried out, specifically: in step 2) take out the impregnation for the second time The impregnated fiber is put into the hydrazine hydrate reducing solution for reduction treatment, and then dried to obtain the modified fiber. Using the same performance test method as in Example 3, the test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com