Preparation method of modified polyester chip, polyester chip and polyester fiber

A technology of modified polyester chips, applied in the field of preparation of polyester chips and polyester fibers, modified polyester chips, can solve the problems of tourmaline superfine powder agglomeration, etc., to achieve environmental and human benefits, long-lasting effect , the effect of low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

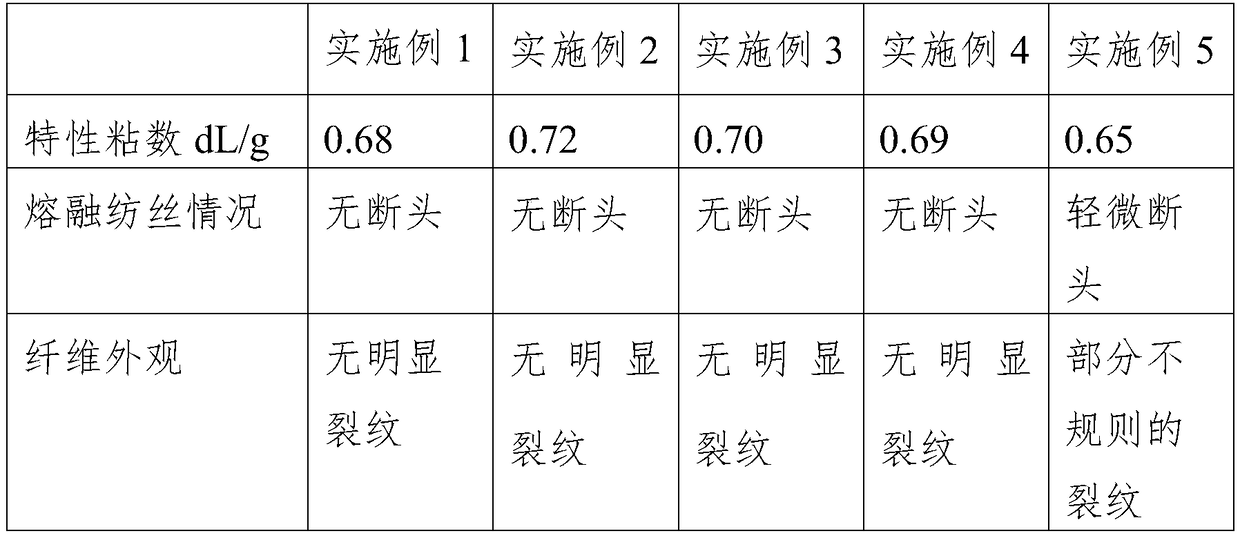

Examples

Embodiment 1

[0041] Add 100 parts of purified terephthalic acid, 1.3 parts of polyhydroxy modified nano tourmaline 1 and 110 parts of ethylene glycol in a container with a stirring bar, a thermometer and a flow divider, and carry out esterification reaction at 250-255 °C, During the reaction process, the generated water was continuously removed, and the viscosity of the reaction intermediate was measured to monitor the esterification rate of the reaction. The reaction was carried out until the esterification rate reached more than 92%, and the temperature was lowered to obtain the esterification intermediate 1.

[0042] Add 100 parts of esterification intermediate 1 and 320 ppm of antimony trioxide into a container with a stirring rod, a thermometer and a vacuum pump, carry out polycondensation reaction at 267° C. for 1.5 hours under a negative pressure of <6000 Pa, and then adjust the negative pressure to 70Pa, react at 270°C for 4 hours, lower the temperature, cast a belt, cool, and pelle...

Embodiment 2

[0044] Add 100 parts of purified terephthalic acid, 3 parts of polyhydroxy modified nano tourmaline 2 and 120 parts of ethylene glycol in a container with a stirring bar, a thermometer and a flow divider, and carry out esterification reaction at 255-260 °C, During the reaction process, the generated water was continuously removed, and the viscosity of the reaction intermediate was measured to monitor the esterification rate of the reaction. The reaction was carried out until the esterification rate was at least 92%, and the temperature was lowered to obtain the esterification intermediate 2.

[0045] Add 100 parts of esterification intermediate 2 and 350ppm of antimony trioxide into a container with a stirring rod, a thermometer and a vacuum pump connected, under a negative pressure of <6000Pa, carry out polycondensation reaction at 270°C for 1.5 hours, and then adjust the negative pressure to 66Pa , reacted at 275° C. for 3 hours, lowered the temperature, cast a belt, cooled, ...

Embodiment 3

[0047] Add 100 parts of purified terephthalic acid, 7 parts of polyhydroxy modified nano tourmaline 1 and 140 parts of ethylene glycol in a container with a stirring bar, a thermometer and a flow divider, and carry out esterification reaction at 270-275 °C, During the reaction process, the generated water was continuously removed, and the viscosity of the reaction intermediate was measured to monitor the esterification rate of the reaction. The reaction was carried out until the esterification rate was at least 92%, and the temperature was lowered to obtain the esterification intermediate 3.

[0048] Add 100 parts of esterification intermediate 3 and 380ppm antimony trioxide into a container with a stirring rod, a thermometer and a vacuum pump connected, under a negative pressure of <6000Pa, carry out polycondensation reaction at 280°C for 1 hour, and then adjust the negative pressure to 60Pa, React at 285°C for 2 hours, lower the temperature, cast a belt, cool, and cut into pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com