Method for cooperatively classifying perceived solid wood panel surface textures and defects by feature extraction and compressive sensing based on dual-tree complex wavlet

A dual-tree complex wavelet and feature extraction technology, which is applied in the fields of instruments, character and pattern recognition, computer parts, etc., and can solve the problems of low classification efficiency and low classification accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

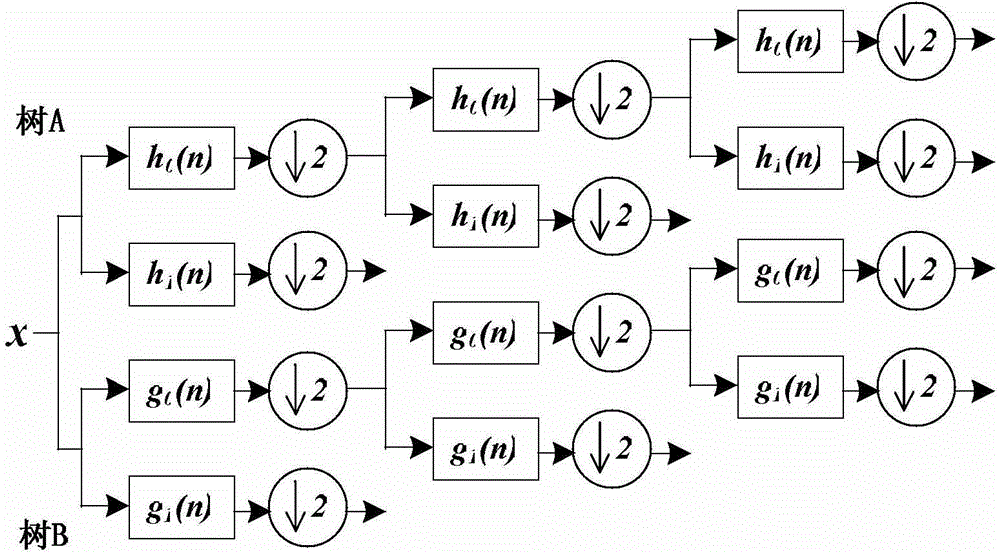

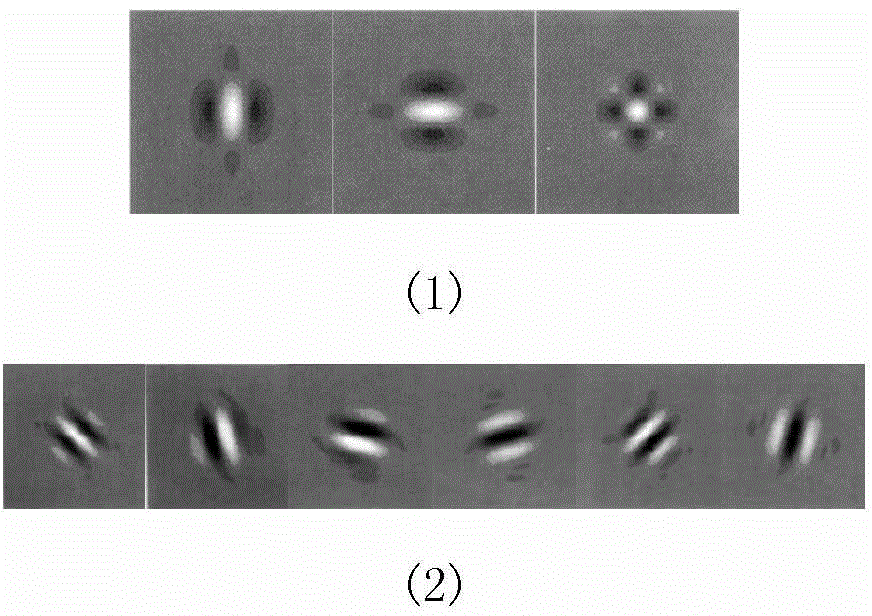

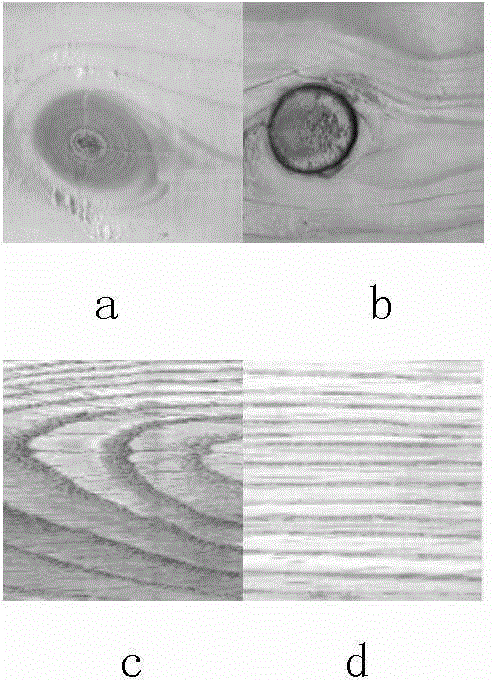

[0055] Specific implementation mode one: as figure 1 As shown, this embodiment describes the method of the present invention in detail: perform three-level dual-tree complex wavelet decomposition on the surface image of the solid wood board, and the good directionality of the double-tree complex wavelet can express complex information on the surface of the solid wood board; Feature selection, feature selection can reduce data redundancy and further improve classification efficiency; finally, using compressed sensing theory, the optimized feature vector is used as a sample matrix column to construct a training sample data dictionary, and the surface of the solid wood panel is processed through the minimum residual error. For classification and identification of information, the compressed sensing classifier has a simpler structure and higher classification accuracy than traditional classifiers. The specific process is as follows:

[0056] 1. Dual tree complex wavelet transform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com