Aircraft engine spindle bearing testing machine

A technology of aero-engine and main shaft bearings, applied in the direction of mechanical bearing testing, etc., can solve the problems that restrict the improvement and perfection of performance parameters of aero-engine main shaft bearings, single structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in conjunction with accompanying drawing and specific embodiment;

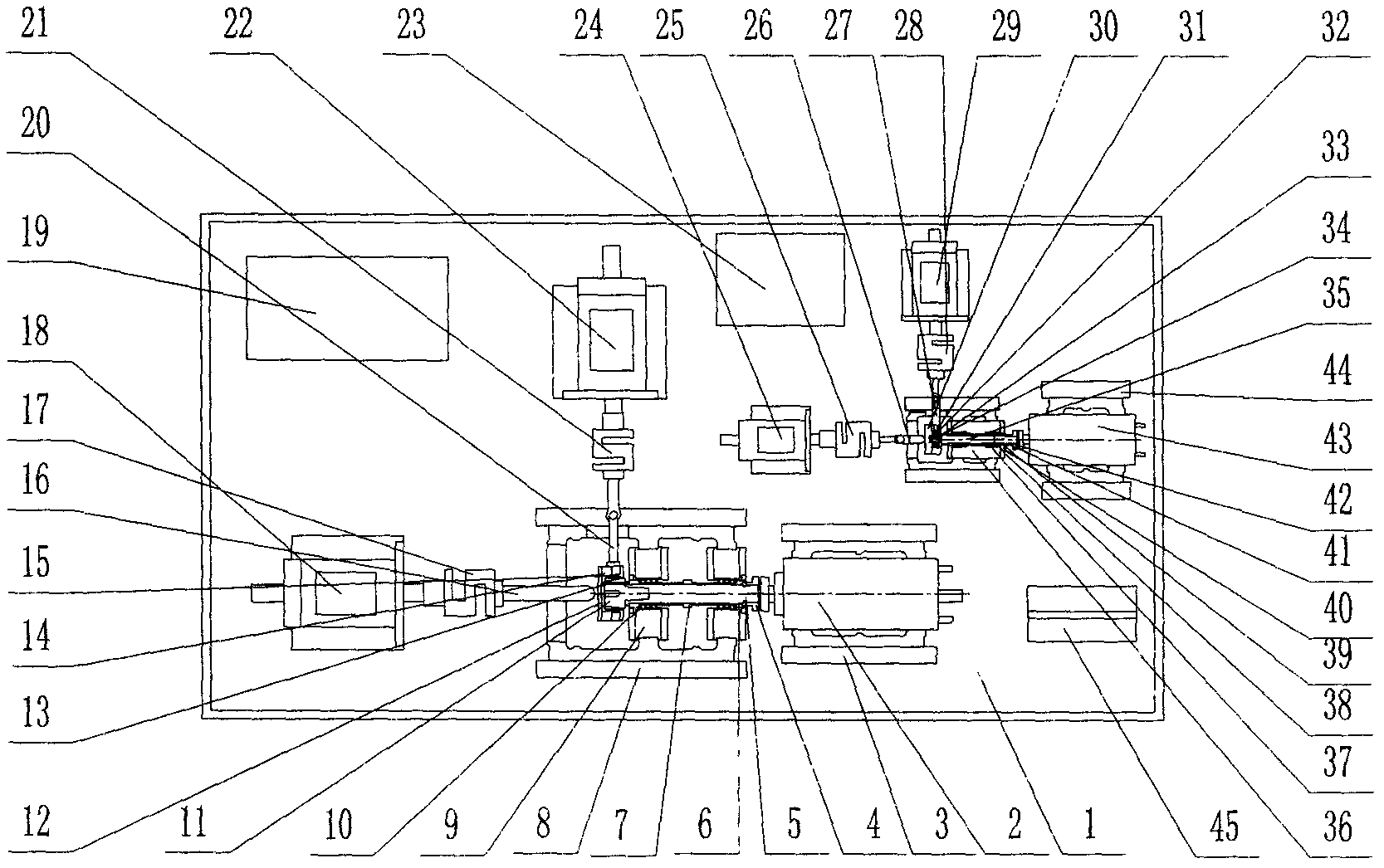

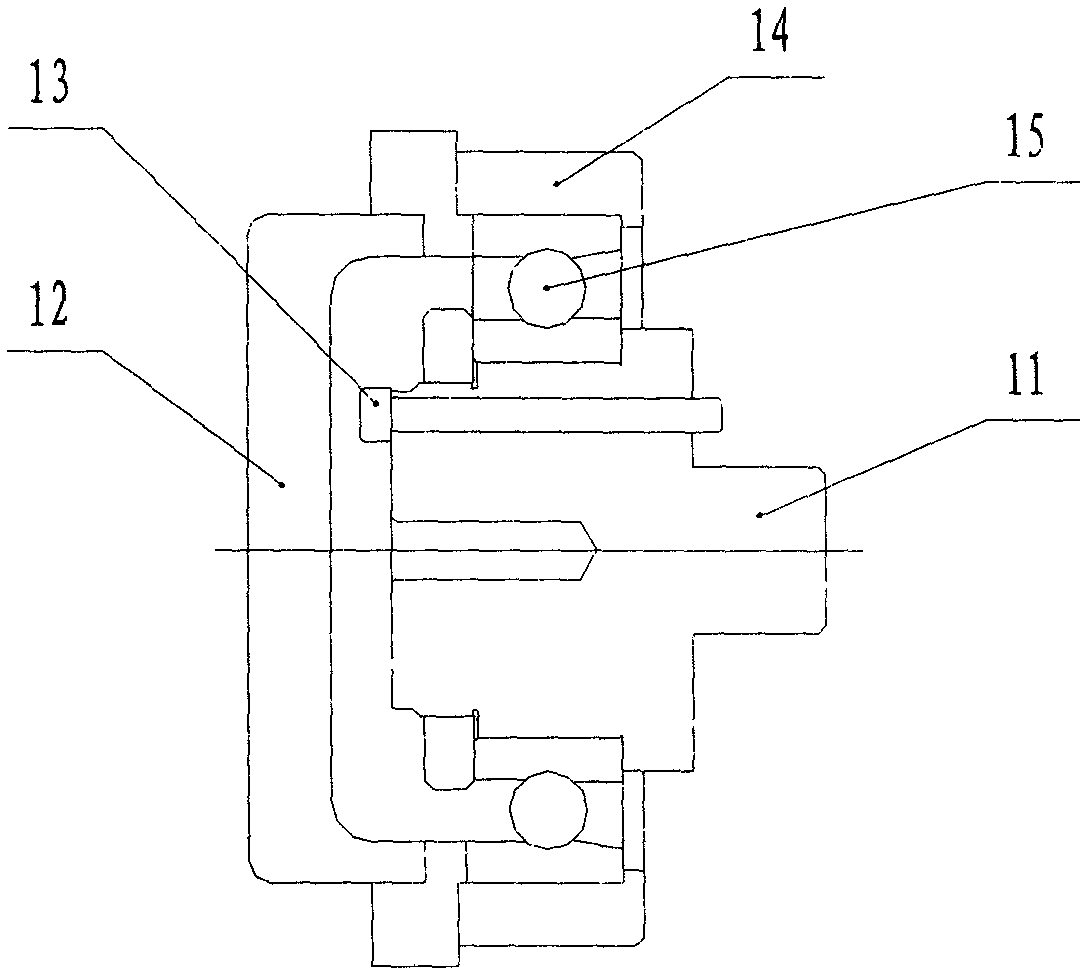

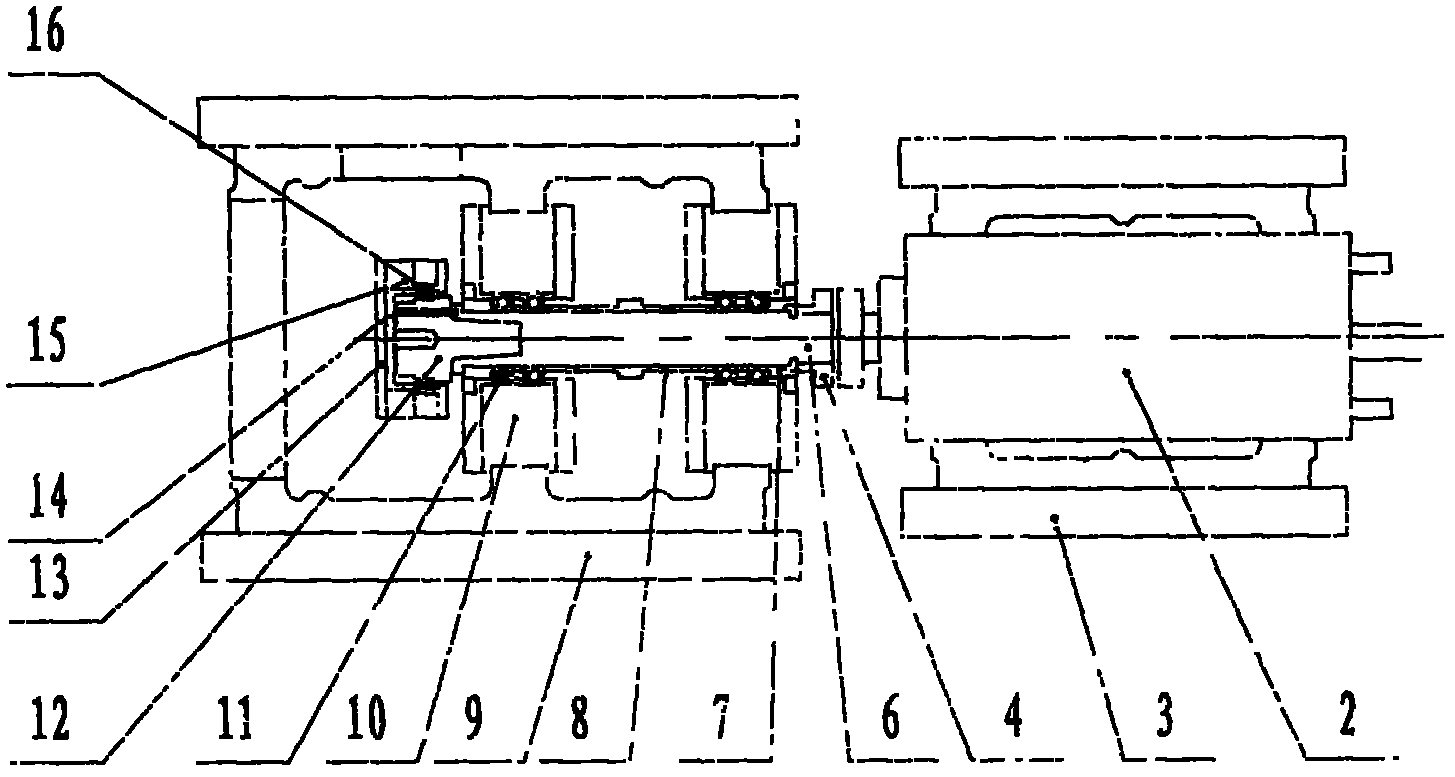

[0019] Such as figure 1 Shown, a kind of aero-engine main shaft bearing testing machine, the test mechanism that described main shaft bearing testing machine has mainly comprises the cantilever support mechanism of test bearing 15, applies the torque of change to test bearing 15 and the axial, radial To the loading mechanism, the driving mechanism, the transmission mechanism and the heating device 23 and the detection collection device for heating the test bearing; the described cantilever support mechanism is used to locate the test bearing 15 and make the test bearing 15 cantilever structure located on the test axis One end of 11 constitutes a relatively rotatable structure between the inner and outer rings of the test bearing 15; The test shaft 11 is connected to form a structure in which the test bearing 15 rotates with the rotation of the electric spindle; there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com