Unmanned aerial vehicle with double engines, four shafts and four rotors

A four-rotor unmanned aerial vehicle, dual-engine technology, applied in the direction of rotorcraft, motor vehicles, aircraft, etc., to achieve the effect of improving stability, prolonging flight time, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

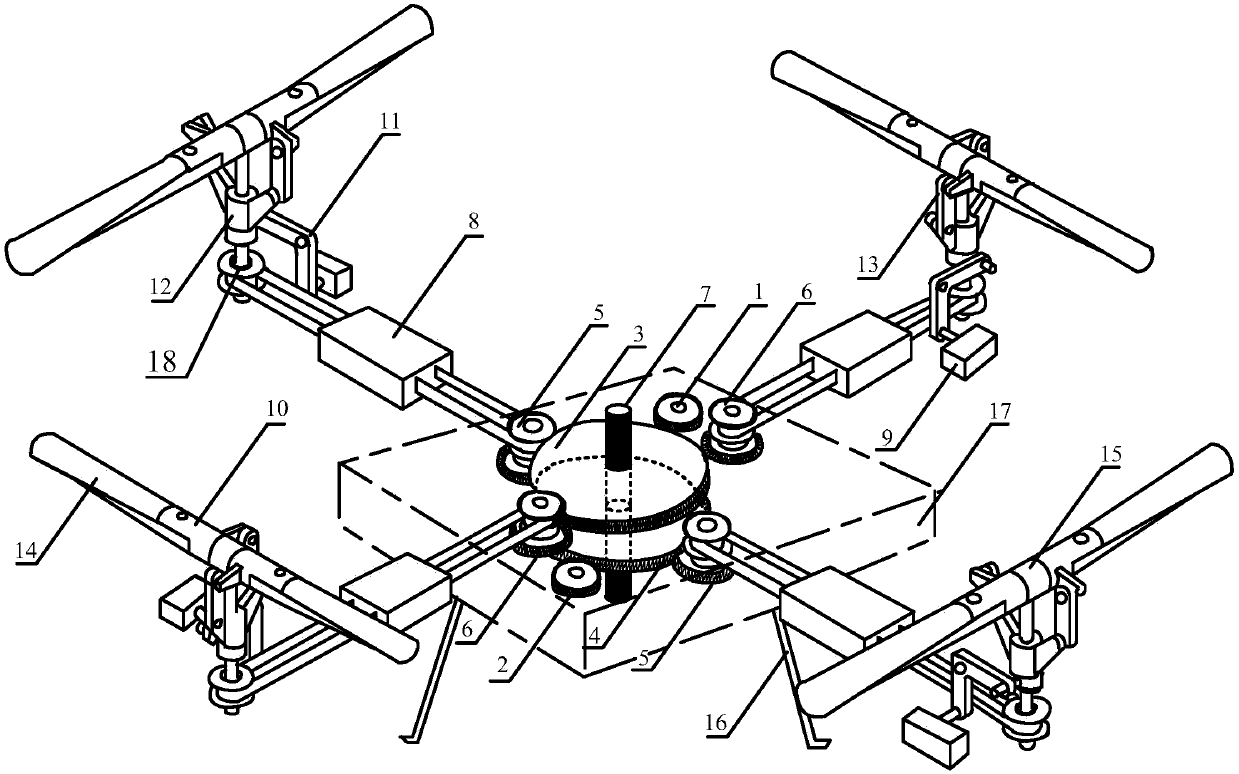

[0010] Such as figure 1 As shown, the dual-engine four-axis quadrotor UAV includes a body, a power transmission device and a rotor assembly; the power transmission device is fixed on the body and connected with the rotor assembly. The rotor assembly includes a steering gear 9 , a rotor clamp 10 , a pitch control arm 11 , a pitch variable slider 12 , a pitch rod 13 , a variable pitch propeller 14 and a rotor clamp base 15 . Two rotor clamps 10 are installed on each rotor clamp base 15, and the two rotor clamps 10 are symmetrically installed along the section where the center of the rotor clamp base 15 is located, and the rotor clamp 10 can be positioned along the rotor clamp base 15. The axis rotates, and one end of the rotor clip 10 and the pitch change rod 13 is hinged by a hinge chain, and can rotate freely with the hinge hole as the center of the circle. The variable pitch slider 12 is sleeved on the rotor rotation input shaft 18, and can move up and down along the axis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com