Virtual assembly-oriented collision detection method based on AABB (Axis Aligned Bounding Box)-OBB (Oriented Bounding Box) mixed bounding box

A technology of collision detection and virtual assembly, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low detection accuracy, slow update, high computing resource requirements, and meet comprehensive requirements and real-time performance and the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

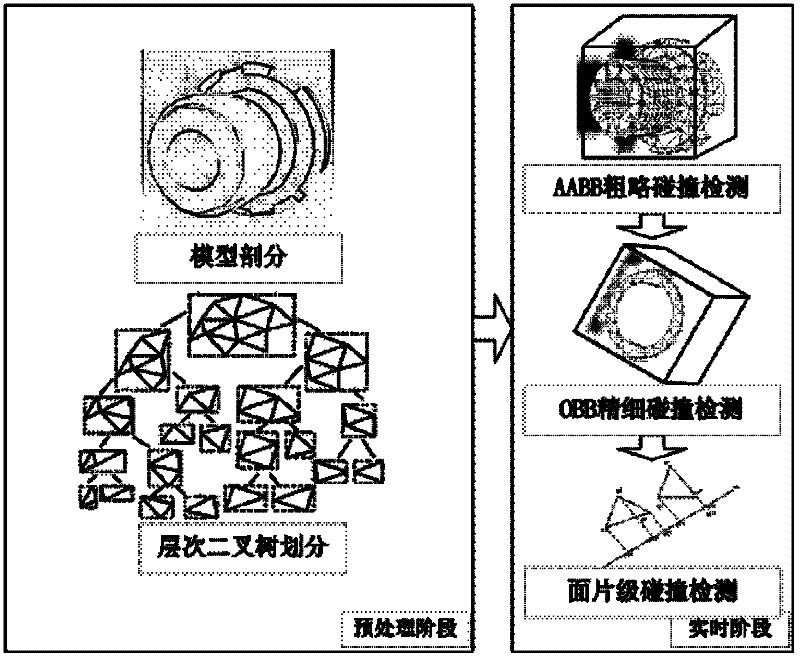

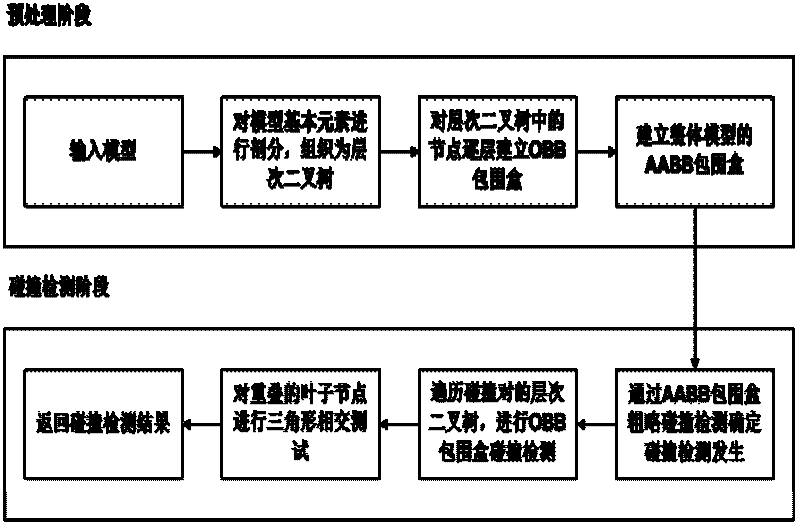

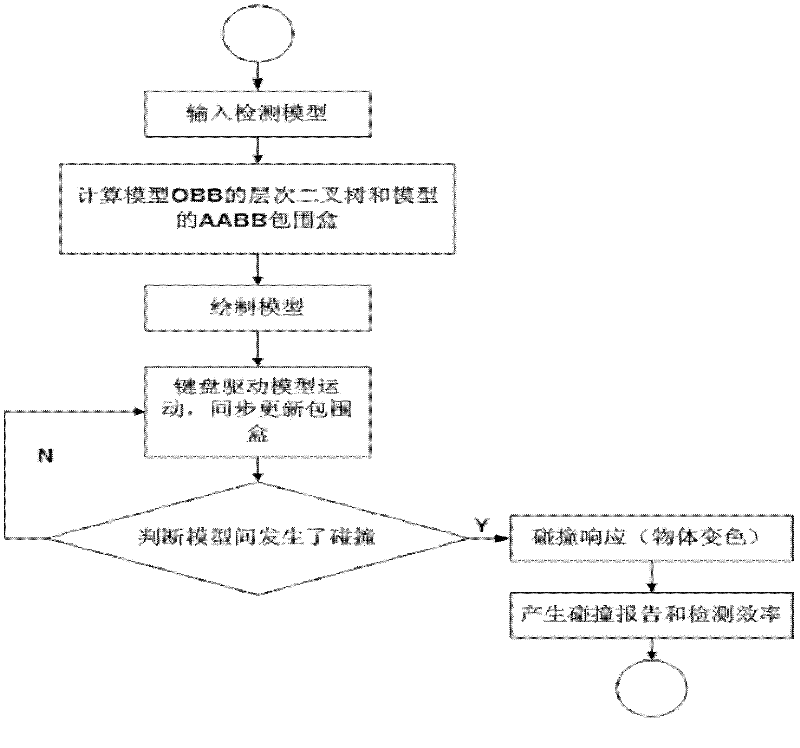

[0020] The main illustration of the present invention is as figure 1 As shown, the algorithm execution framework is as follows figure 2 As shown, the experimental procedure is as follows image 3 As shown, the specific steps are as follows:

[0021] (1) Load the model, usually load the model in OBJ format, and extract the vertex information, vertex normal information, triangle patch information, etc. of the model according to the file line tags v, vn, f respectively.

[0022] (2) According to the extracted model information, in the pre-processing stage, the model is divided, and the OBB level binary tree is divided. Build the AABB bounding box of the model as a whole. By continuously dividing the mesh model, the whole model is organized into a hierarchical bounding volume tree. Based on the real-time requirements, this process i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com