Aerial engine lean premixed preevaporated low contamination combustion chamber

An aero-engine and combustion chamber technology, which is applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of difficult to achieve low-polluting combustion, uneven local equivalence ratio, etc., and achieve improved wall-beating effect, wide stability and low pollution Emissions, the effect of reducing the circumferential injection point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

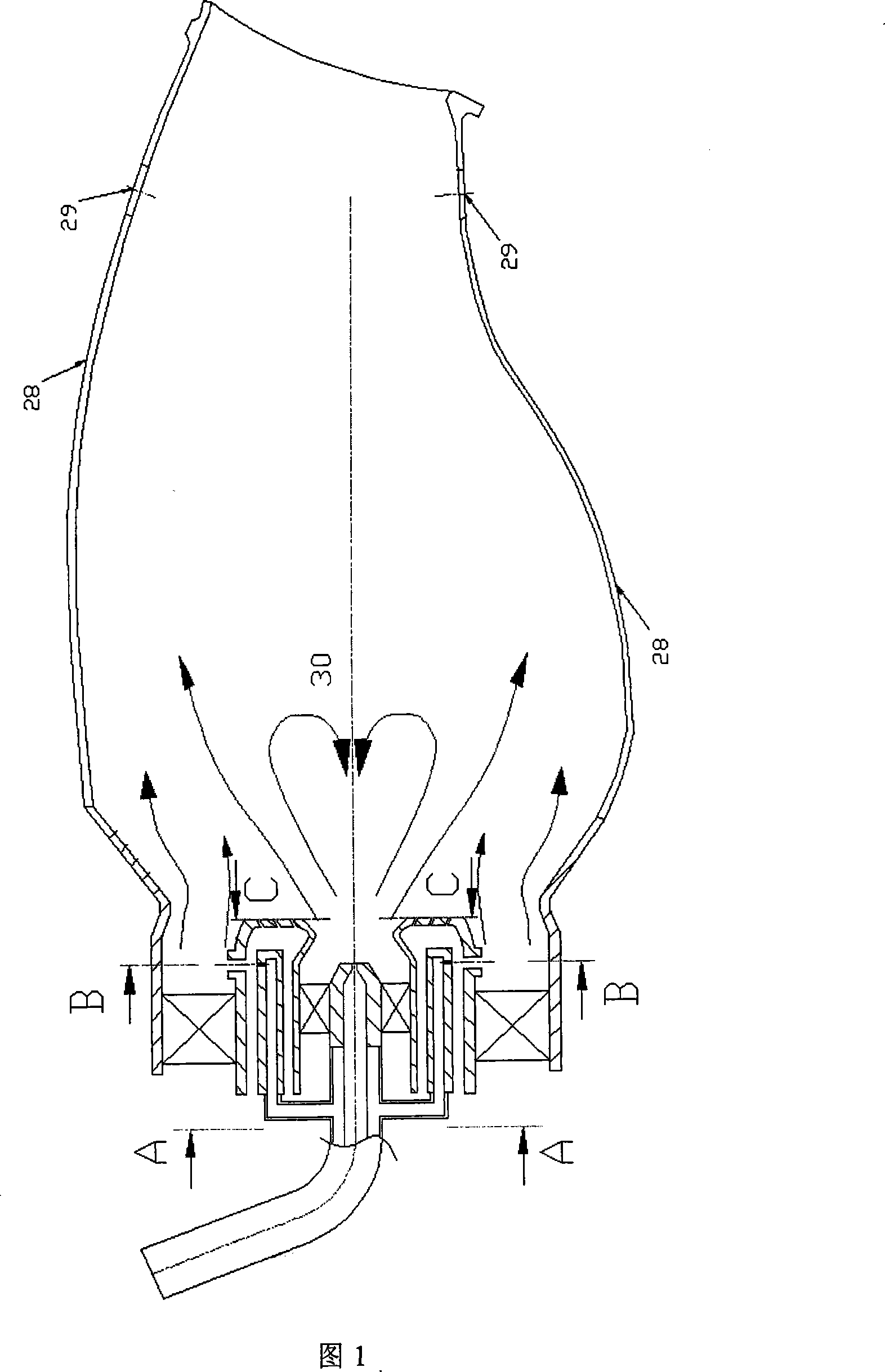

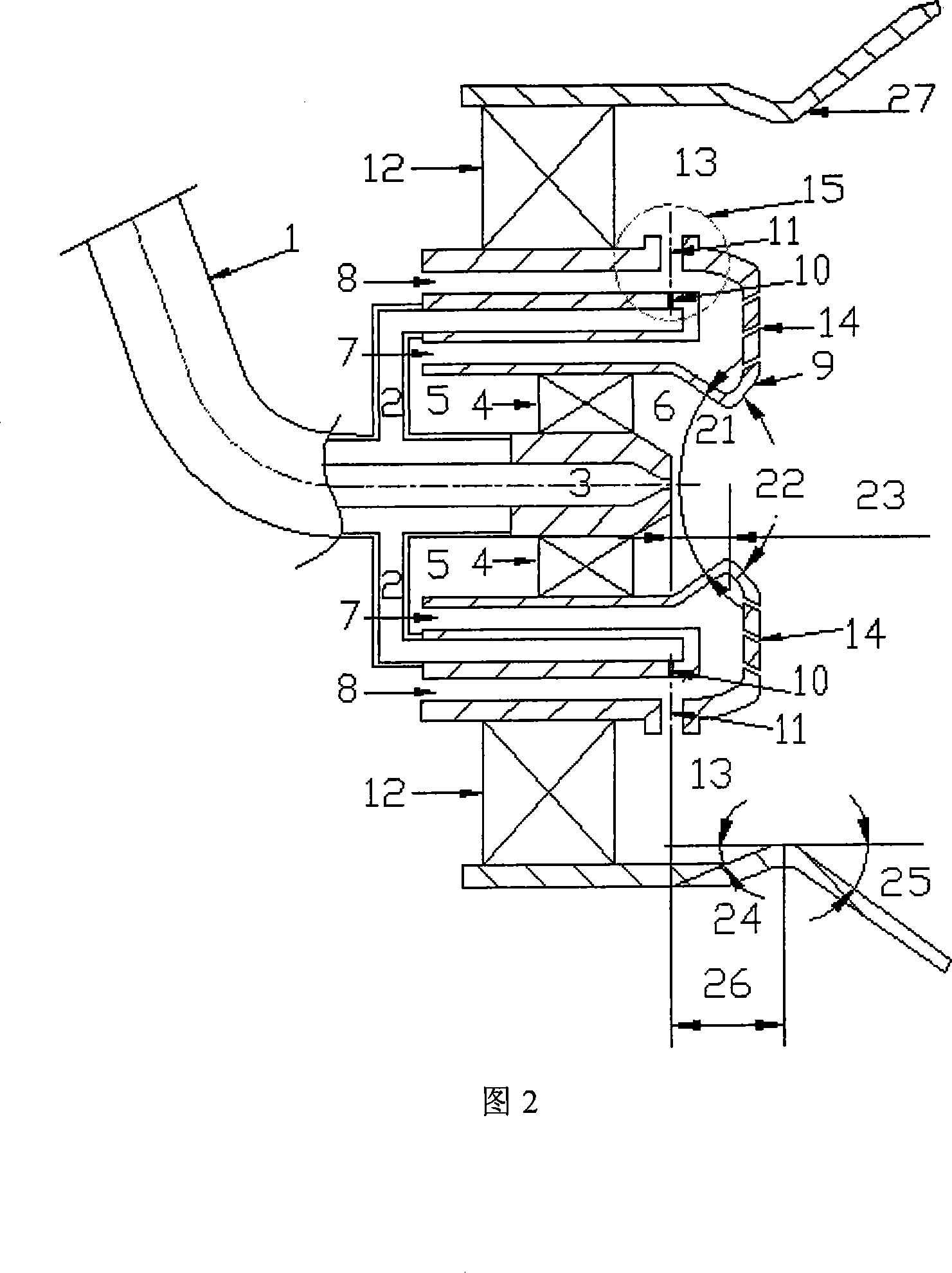

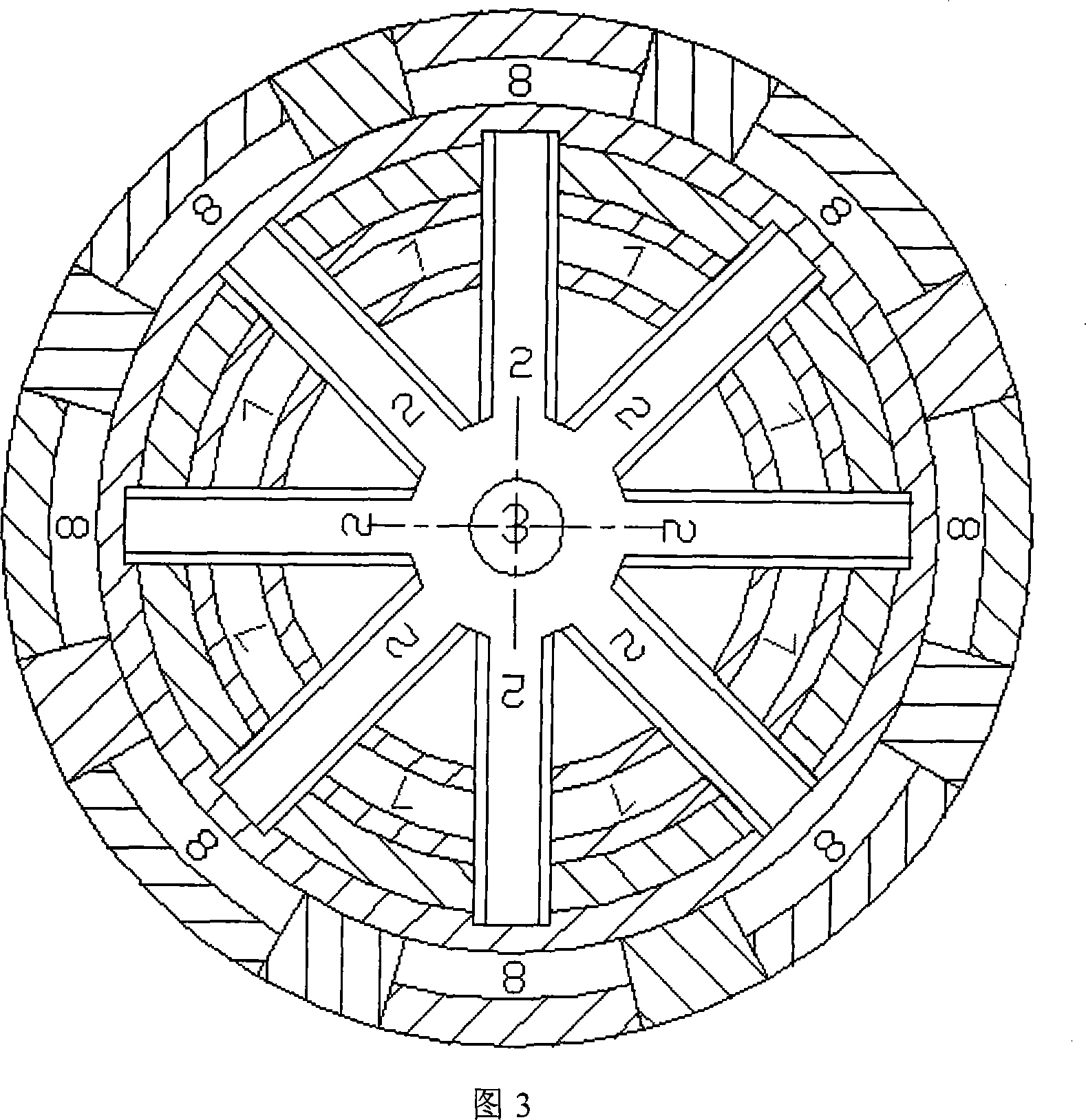

[0024] As shown in Figures 1, 2, and 3, the combustion chamber designed by the present invention is composed of a head and a flame tube. Mixing holes 29 are provided to adjust the outlet temperature distribution of the combustion chamber. The main structure of the head is a circular annular cavity structure, which is divided into a pre-combustion stage and a main combustion stage. The pre-combustion stage includes a centrifugal nozzle 3 and a swirler 4 surrounding the centrifugal nozzle; the main combustion stage surrounds the pre-combustion stage, including Direct air atomizing nozzle 15, main swirler 12 and pre-mixing ring chamber 13. The oil circuit 2 and the oil nozzle 10 of the pre-combustion stage centrifugal nozzle 3 and the main combustion stage air atomizing nozzle 15 can be processed into a whole oil supply, including the mixing nozzle 11 of the direct-injection air atomizing nozzle 15, the pre-combustion stage closing and expanding port A plurality of parts includi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com