Five-axis plunge milling method of aeroengine crankcase

An aero-engine and processing method technology, applied in the field of milling, can solve the problem of not having the function of five-coordinate variable-axis plunge milling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] 1 Select the appropriate plunge milling tool according to the material and structure of the part;

[0083] The plunge milling tool is selected according to the part material and the shape and surface characteristics. The processing material is INCOL 718 nickel-based superalloy. The larger area uses a φ40 plunge milling cutter, and the rather narrow area uses a φ32 plunge milling cutter.

[0084] Determine the plunge milling process parameters according to the selected plunge milling tool;

[0085] F40M plunging milling blade specification is 12×6, in principle, the width of plunging and milling should not exceed the width of the blade, generally select 1 / 2 of the width of the blade as the width of plunging and milling, the cutting speed is 40 m / min, each tooth cuts 0.2mm deep.

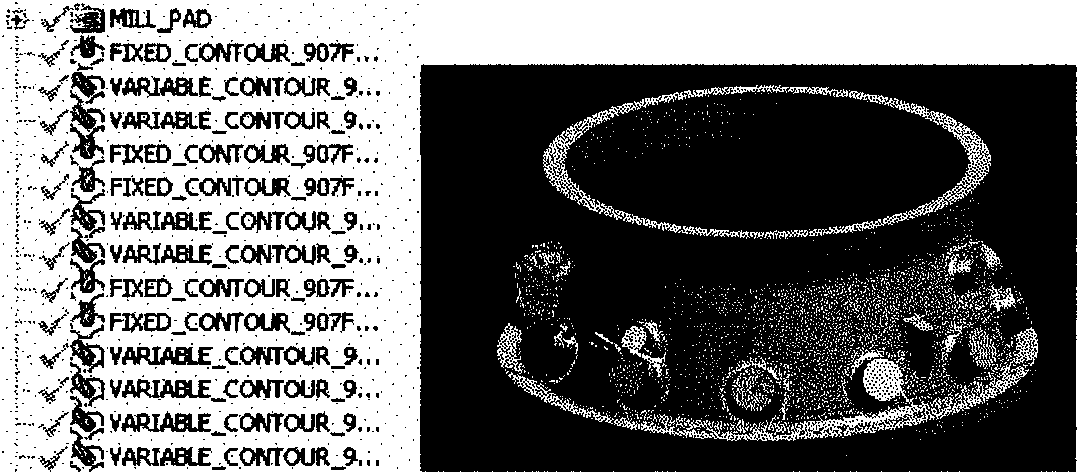

[0086] 2Use the multi-axis milling function of UG software to generate a tool path with a fixed step;

[0087] On the UG platform, the multi-axis machining method is adopted, and the variable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com