Three-hole transonic speed pressure probe

A transonic and transonic flow technology, which is applied in the measurement of fluid pressure, fluid velocity measurement, velocity/acceleration/impact measurement, etc., can solve the problems of total pressure loss, requirements, and less use, and achieve the reduction of total pressure loss in the flow field Small, not easy to blow and bend, with little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

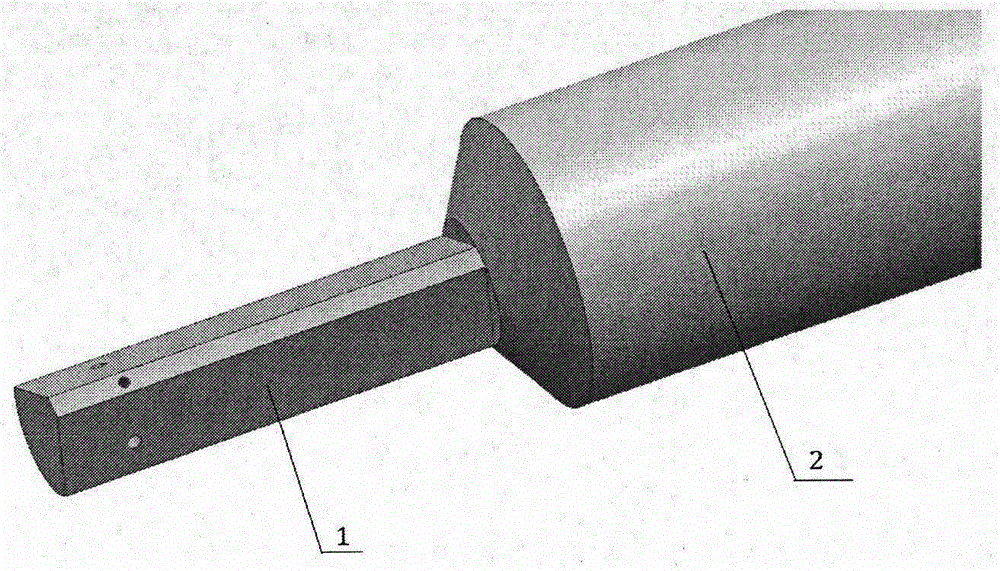

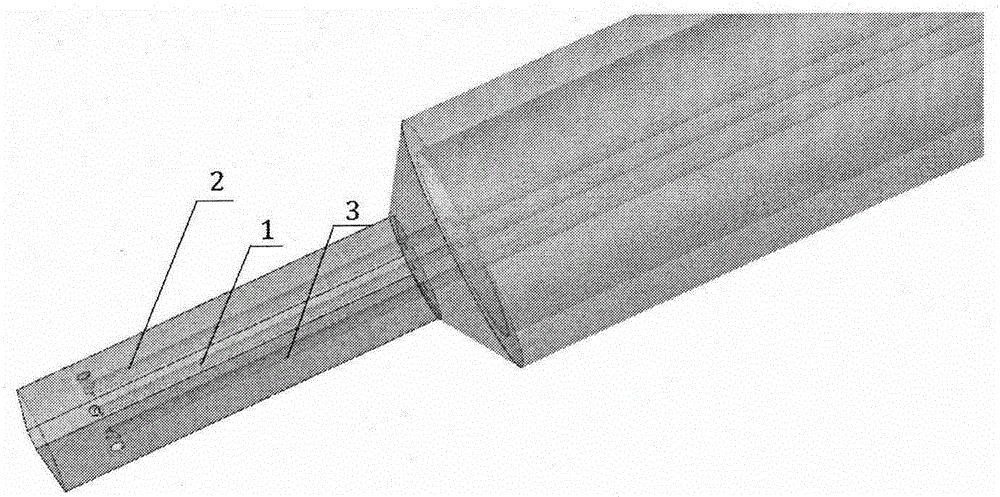

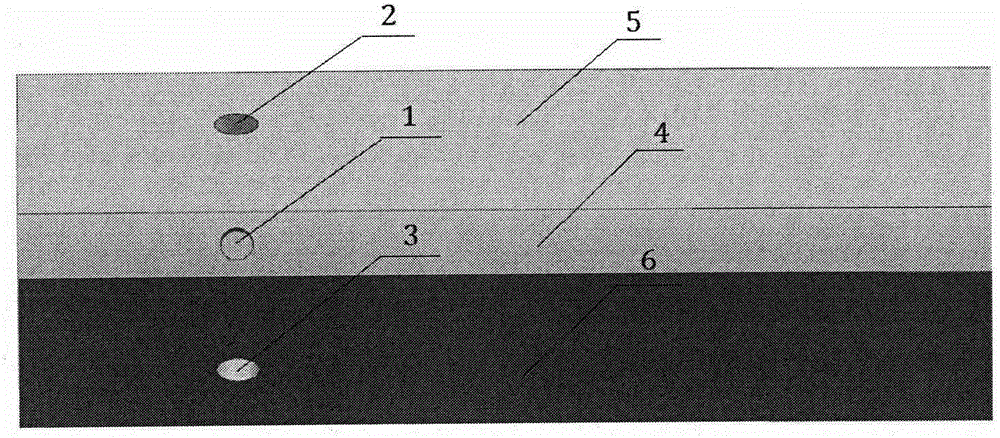

[0013] Such as figure 1 As shown, the probe probe is installed on the probe support rod, and the probe is made into a shape where the wedge and the circular table are connected, and the front and back of the wedge are arc surfaces. Open a pressure introduction hole on the front arc of the probe, and open a pressure introduction hole at the same position on the left and right sides of the probe wedge, as image 3 shown. The pressure of the three holes is led out by the pressure pipe along the probe rod, such as figure 2 shown. In this way, the aerodynamic resistance of the probe is not only small, which ensures the firmness and reliability of the probe, but also weakens the shock wave intensity in front of the probe and reduces the influence of the probe on the flow field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com