Method for transition between controlled auto-ignition and spark ignition modes in direct fuel injection engines

一种发动机、燃烧模式的技术,应用在燃烧发动机、发动机控制、内燃活塞发动机等方向,能够解决升高最大速率或压力波动幅度、高负载限制扩大、不希望燃烧结果等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

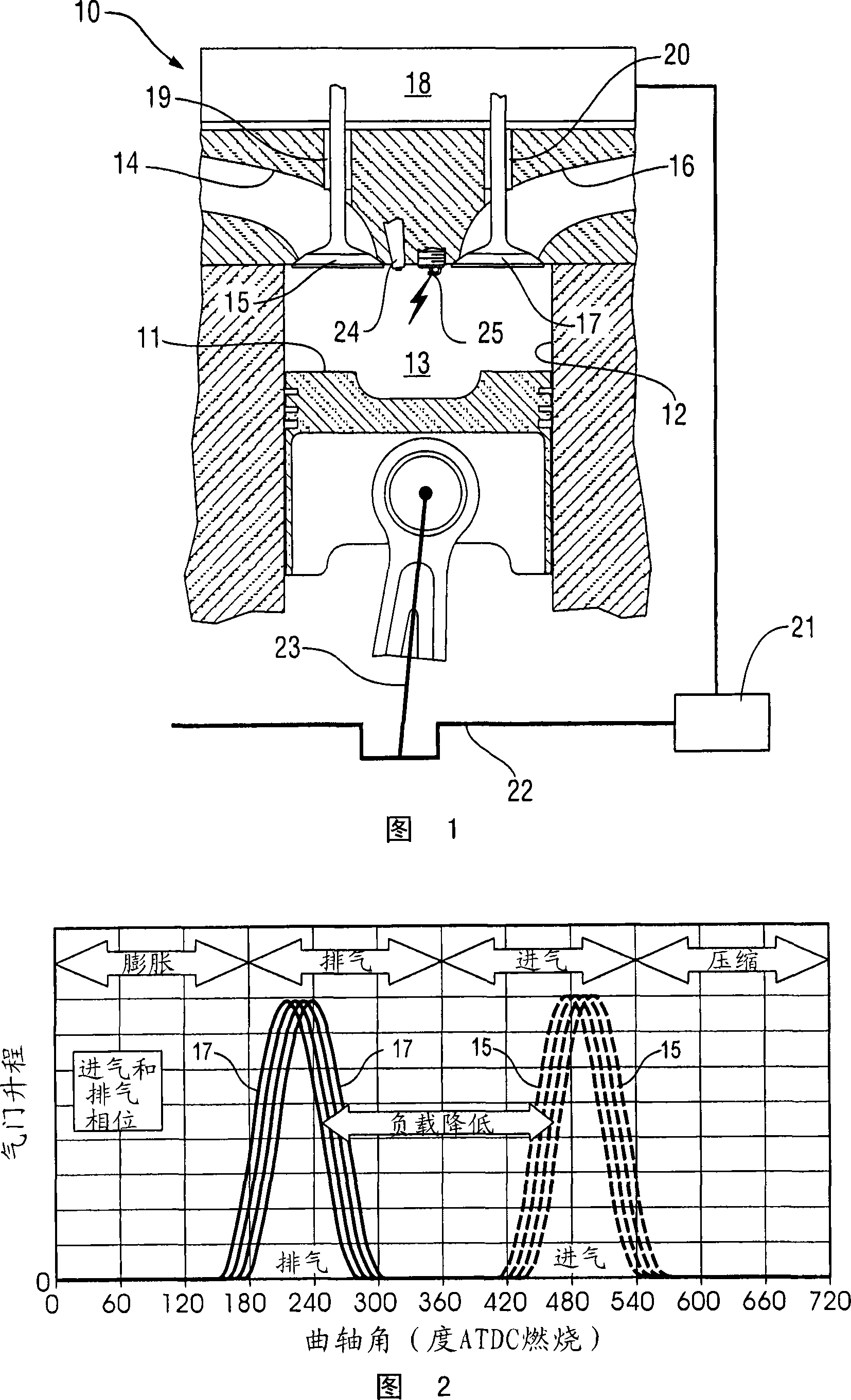

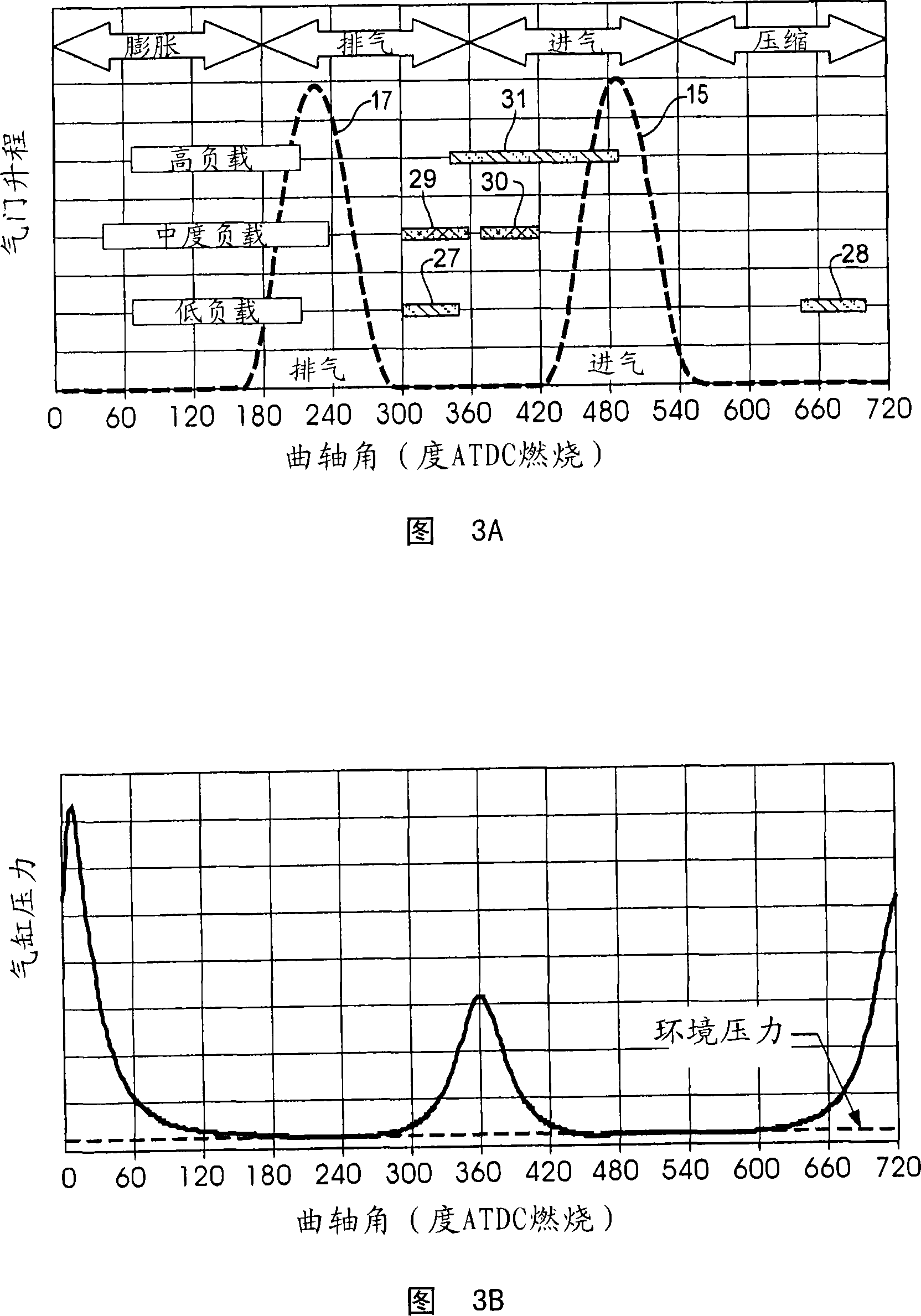

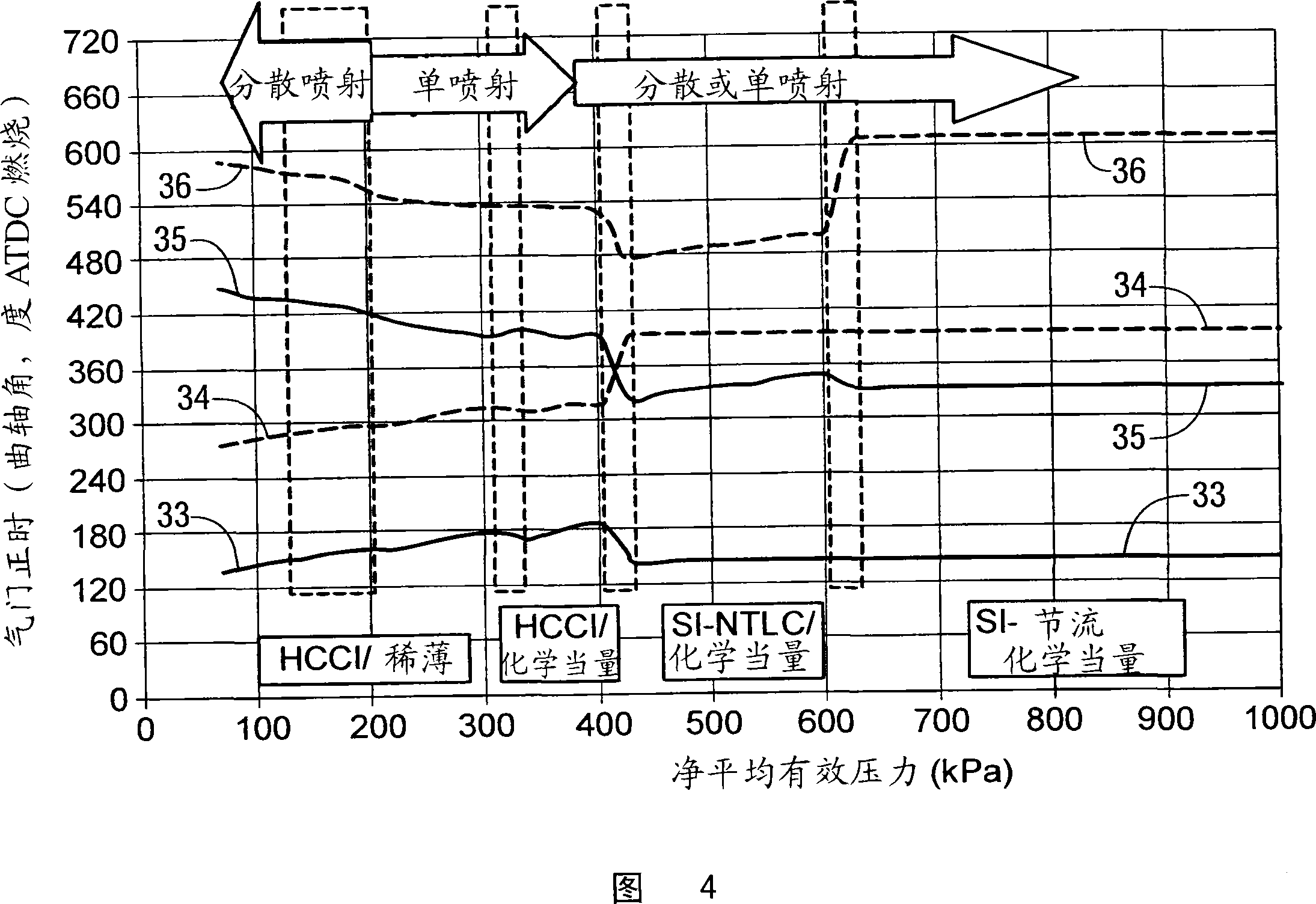

[0037] For the sake of brevity, the following description explains the present invention through a single-cylinder direct-injection gasoline four-stroke internal combustion engine in its application, but it should be understood that the present invention is also applicable to multi-cylinder direct-injection gasoline four-stroke internal combustion engines. A four-stroke single-cylinder 0.55-liter internal combustion engine is used to realize various controls and various data acquisitions described herein. Those of ordinary skill in the art will understand that all such implementations and acquisitions are assumed to be performed under standard conditions unless specifically described otherwise. The invention is described in its application to a two valves per cylinder engine (one intake valve and one exhaust valve), but it should be understood that the invention is equally applicable to engines with multiple valves per cylinder. Also, while the present invention is applicable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com