Method for controlling diluent or lean mixed gas burning and ignition through high-flammability fuel micro ignition

A lean-burn, fuel technology, applied in fuel injection control, electrical control, engine control and other directions, can solve the problems of high pressure rise rate of gasoline engine under heavy load, lack of ignition control method for gasoline compression ignition combustion, high pressure, etc. Effects of improved economy, improved fuel economy, and reduced NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

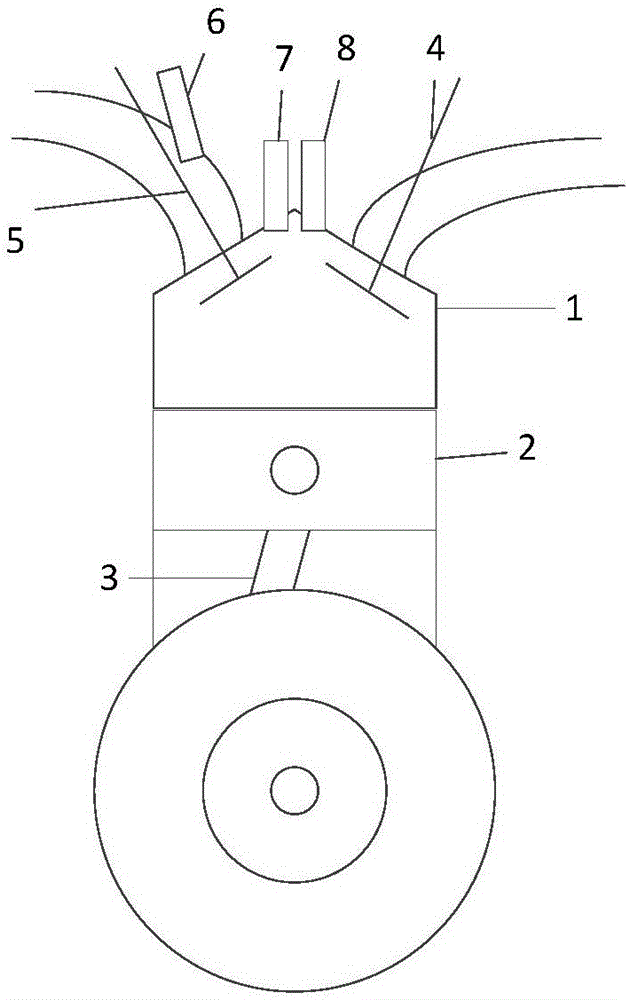

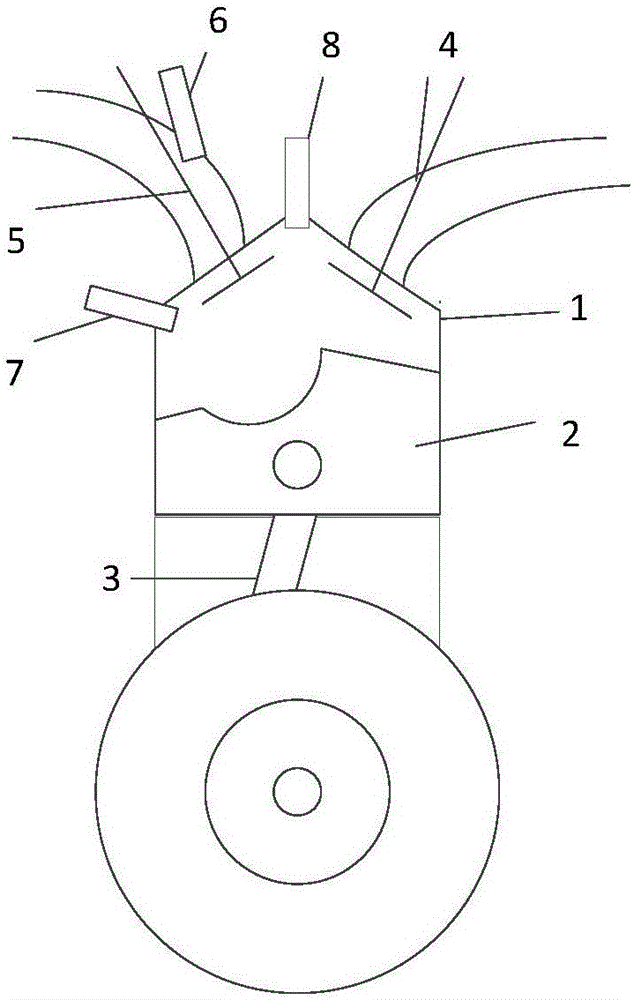

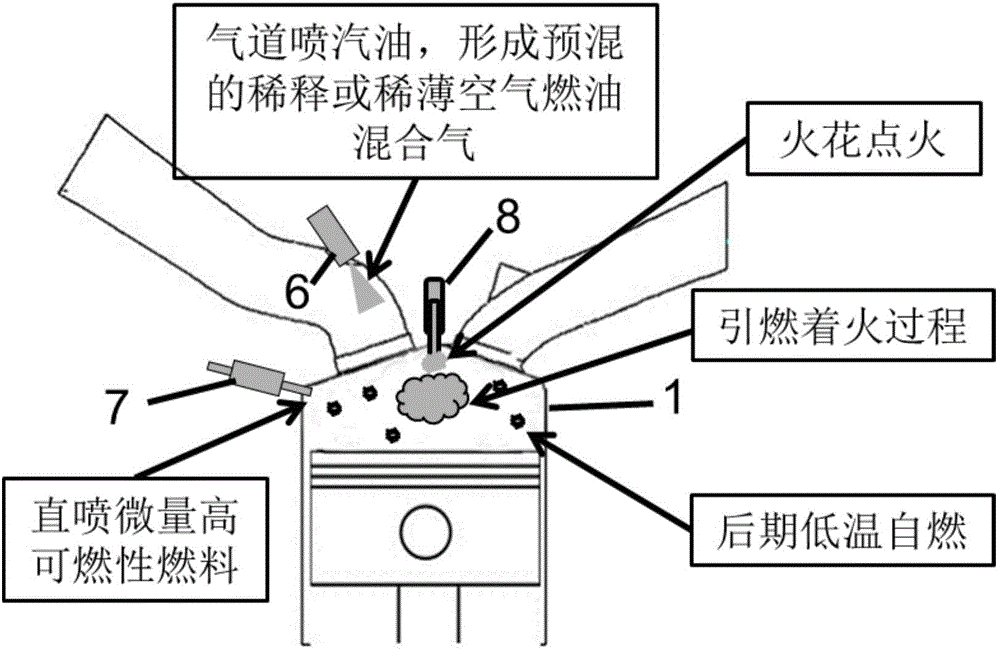

[0035] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

[0036] In the present invention, the energy released during the micro-ignition process of early injection of highly flammable fuel is distributed as a small heat source group in a spatial area, and the auxiliary premixed diluted mixture produces multiple spontaneous ignition points, and then multi-point spontaneous combustion or rapid ignition occurs. combustion. The micro-ignition process of late injection of highly flammable fuel is to strengthen the flame propagation process through the self-ignition of highly flammable fuel to generate a large number of concentrated micro-ignition sources, so that the rest of the diluted air-fuel mixture or lean air-fuel mixture can obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com