Experimental device for cutting off carbon fiber composite material

A composite material and experimental device technology, applied in the direction of testing machinability, etc., can solve the problems of not having the functions of force measurement, temperature measurement, workpiece heating, chip follow-up collection, inability to install microscope heads and high-speed cameras, and achieve automation. The effect of high degree, good processing flexibility and reasonable design layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

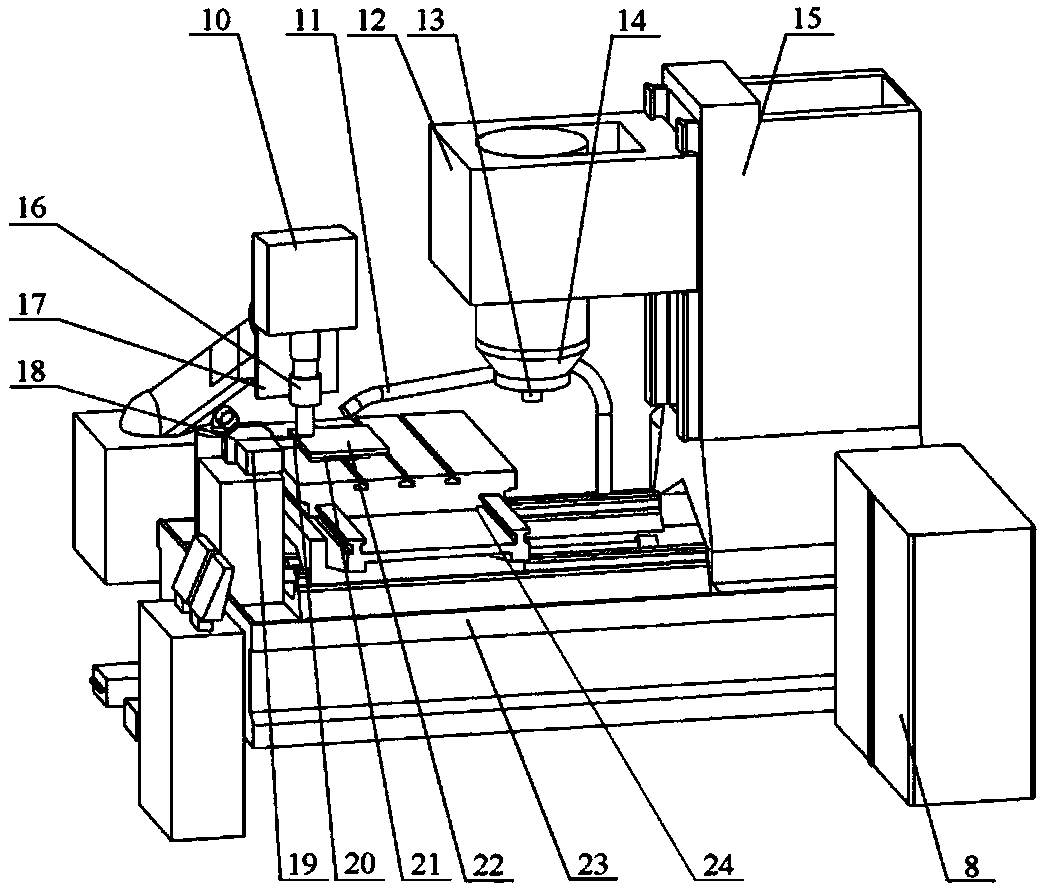

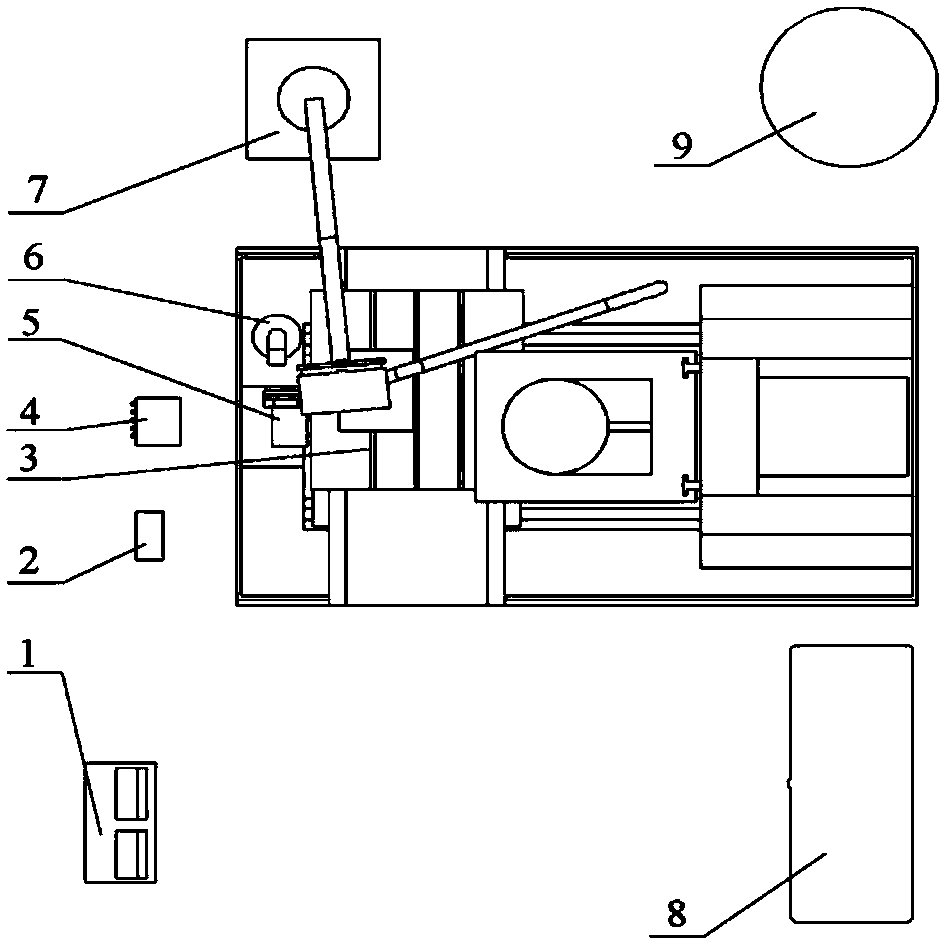

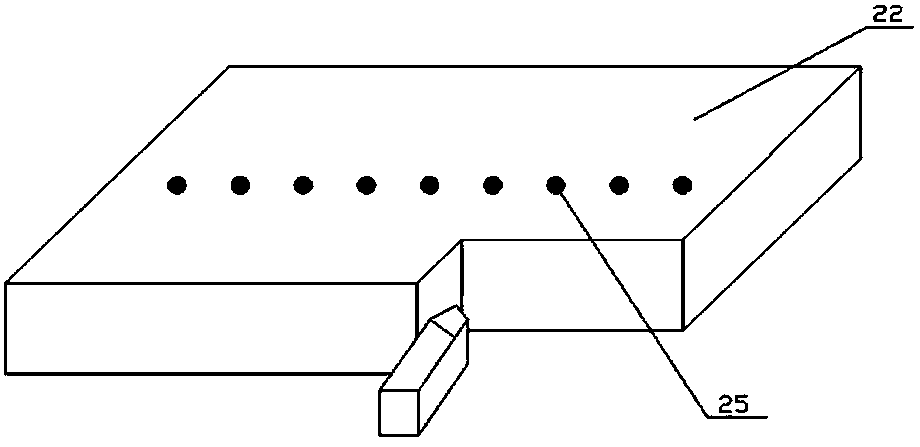

[0014] The specific implementation of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings. in the attached figure 1 , 2 Among them, the bed 23 in the cutting device is the basic supporting part of the whole cutting device; the bed is equipped with an XY linear displacement platform 24, and the X-axis is combined with a linear motor and a linear guide rail pair to realize linear motion with a wide range of speeds, and the highest linear speed It can realize 240m / min; Y-axis is combined with servo motor, ball screw pair and linear guide rail pair to realize linear motion, the maximum speed is 20m / min, XY linear displacement platform 24 realizes precise adjustment of processing position and feed cutting; bed The column 15 is provided with a spindle box 12, and the Z-axis is combined with a servo motor, a ball screw pair and a linear guide pair to realize the up and down linear motion of the spindle box 12, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com