Carbon dioxide blasting impact dynamic monitoring test device and test method thereof

A dynamic monitoring, carbon dioxide technology, applied in measurement devices, suspension and porous material analysis, instruments, etc., can solve the problems of lack of scientific evaluation model for the increase of field permeability, error of field anti-reflection effect, hidden dangers of safety production, etc. To achieve the effect of convenient blasting performance parameters, conducive to docking, and avoid disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

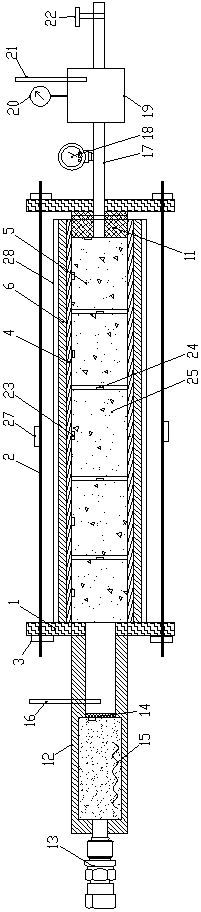

[0030] like Figure 1-3 As shown, the carbon dioxide explosion shock dynamic monitoring test device of the present invention includes CO 2 Blasting Shock Test System, CO 2 The blasting impact test system is equipped with a dynamic stress test system and a static stress test system;

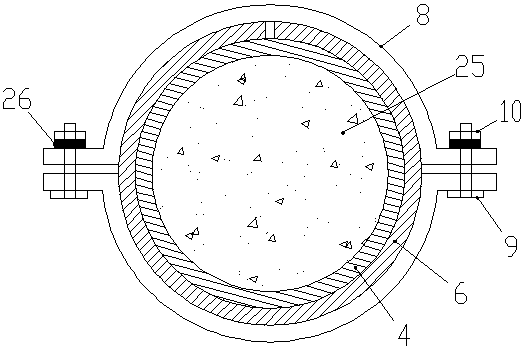

[0031] CO 2The blasting impact test system consists of a stress loading mechanism, a blasting impact mechanism and a gas collection mechanism. The stress loading mechanism includes a stress loading part of the test piece and two flanges 1. The two flanges 1 are arranged side by side. Between the two flanges 1, several steel tie rods 2 are connected between the two flanges 1, and the two ends of each steel tie rod 2 are provided with external threads, and the two ends of the steel tie rods 2 are Fastening nuts 3 are threaded respectively, and the two fastening nuts 3 are press-fitted with the two flanges 1 respectively;

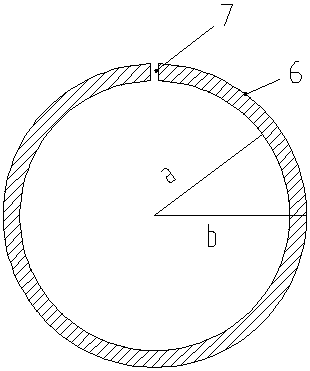

[0032] The stress loading part includes a thermoplastic sealing tube 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com