Vertical hydraulic tensioning device of round pipe belt conveyer

A round tube belt type, tensioning device technology, applied in the direction of conveyor, transportation and packaging, can solve the problems of reducing the service life of the tension roller and conveyor belt, increasing the resistance of the round tube belt conveyor, etc., and achieves a compact structure. , The installation space is small, the effect of reducing the impact dynamic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

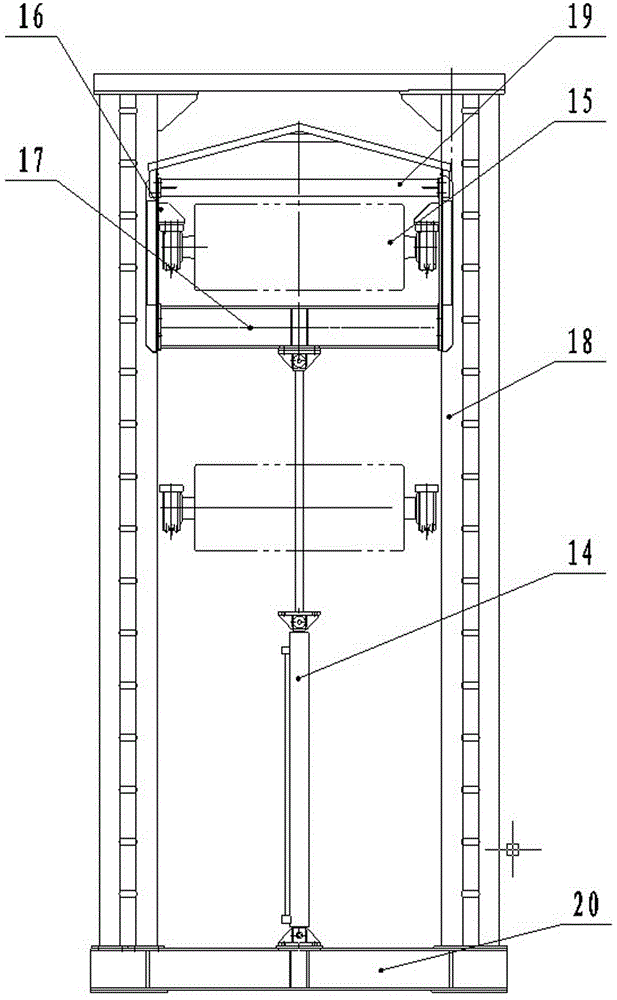

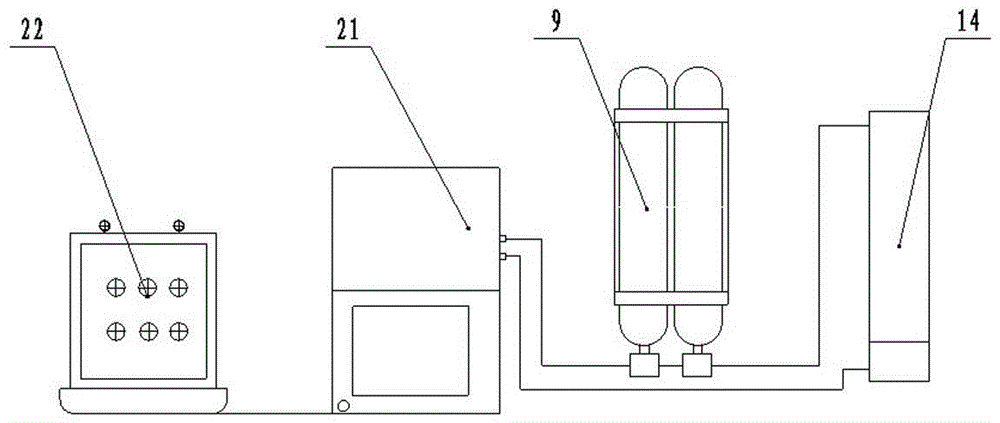

[0021] The present invention is made up of tensioning drum 15, upper beam 19, limit support 16, lower beam 17, guide rod 18, tensioning oil cylinder 11, hydraulic station 21, accumulator 9, electric control box 22.

[0022] Such as figure 2 As shown, the bearing seats at both ends of the tensioning drum 15 are fixed on the limit bracket 16, and the upper beam 19 and the lower beam 17 are respectively placed on and below the tensioning drum 15 and connected with the limit bracket 16 to form an integral frame. The guide rod 18 is mounted on two ends of the guide rod base 20 . The whole frame slides up and down along the guide rod 18, and the guide rod 18 limits the left and right swing of the whole frame. Tensioning oil cylinder 11 fixed hinge lug is installed in the middle of guide rod base 20, and tensioning oil cylinder 11 is hinged with lower beam 17 in the middle.

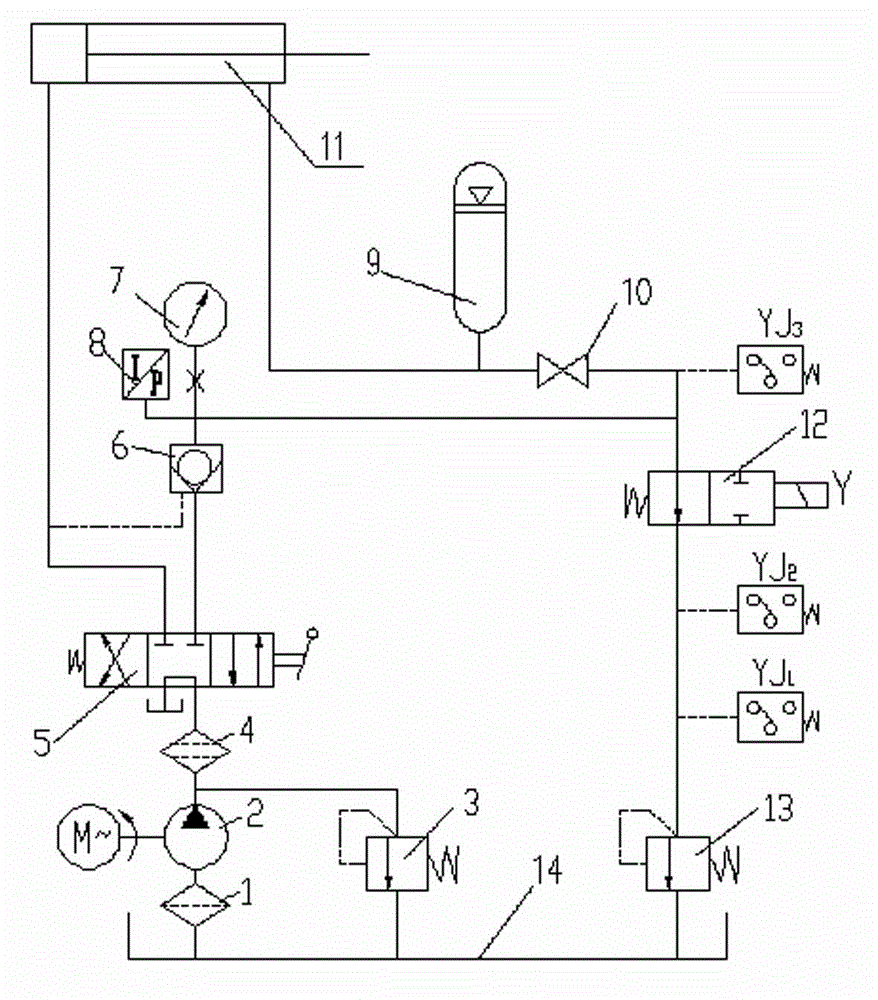

[0023] Such as image 3 As shown, the tension cylinder 11 has a rod chamber oil port connected with the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com