Experimental method based on tensile stress lasting time serving as variable, and impact experiment device

A technology of duration and tensile stress, which is applied in the direction of measuring devices, testing material strength and instruments using one-time impact force, can solve the problems of impact test accuracy, influence plane, and deviation of lamellation change, and achieve improvement Efficiency, simple structure, effect of achieving tensile stress amplitude and tensile strain rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] At present, the commonly used scheme in the spallation experiment is to change the thickness of the flyer or the sample (or change both at the same time) to realize the control of the tensile stress duration, but the change of the tensile stress duration in the experiment is limited. There is a large deviation between the spalling change caused by the same value of the theoretical tensile stress duration change and the spalling change, which seriously affects the accuracy of the experiment and the follow-up analysis and research on the data.

[0045] The present invention provides an experimental method with tensile stress duration as a variable to improve the above problems.

[0046] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

[0047] In the present invention, the first, second, third, etc. are all different indications, and are not limiting.

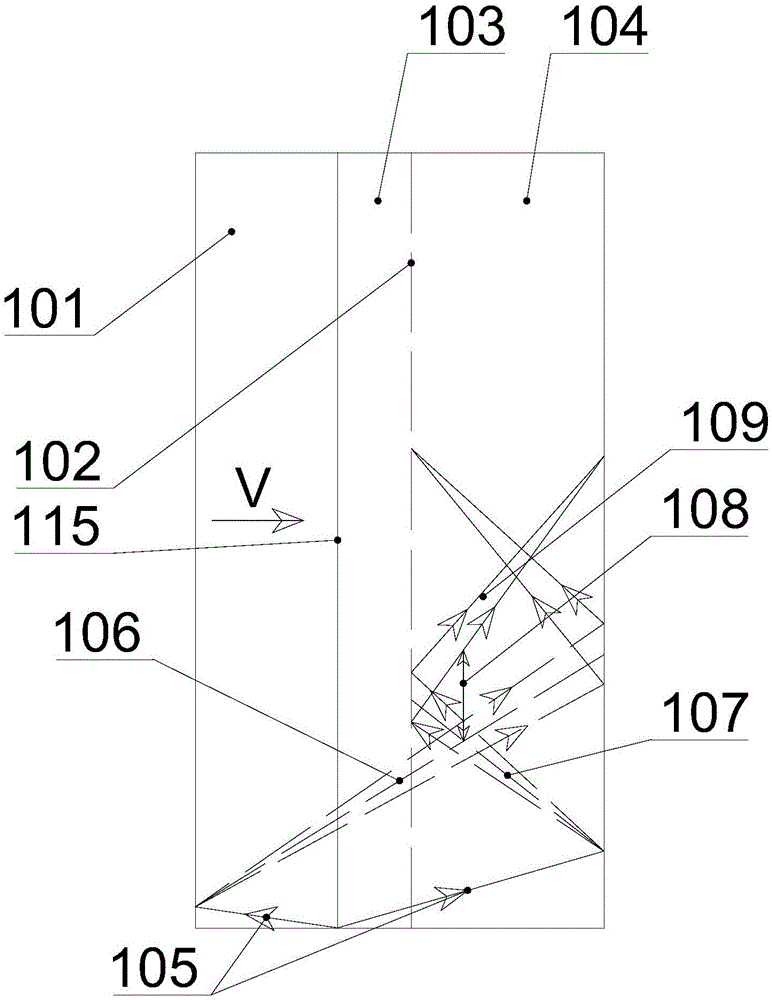

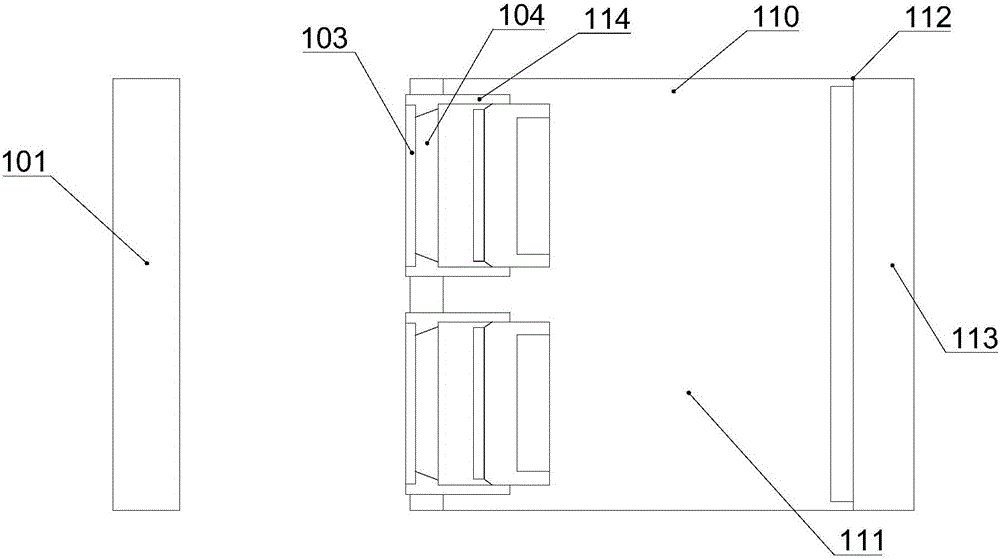

[0048] figure 1 It is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com