Three-dimensional impact loading experiment device

A technology of loading experiment and loading device, which is applied in the direction of measuring device, using repeated force/pulsation force to test the strength of material, instruments, etc., to achieve the effect of improving accuracy and ensuring synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

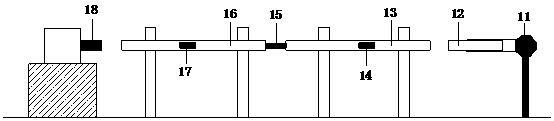

[0051] Influence of the incident rod on the waveform

[0052] (1) A single loading rod ensures synchronization

[0053] If three one-dimensional SHPB pressure rods act on the specimen from three directions, there must be three loading rods, and the loading rods need to be pushed by the gas in the firing gun. Three loading rods need three solenoid valves. The minimum opening time of the solenoid valve is also on the order of microseconds, while the propagation speed of the shock wave in the rod is more than 5000 meters per second, that is to say, the opening time of the two valves is at least different , that is, it spreads as much as 5mm in the rod. For a SHPB compression rod with a diameter of 50mm, the thickness of the general specimen is only 1 to 20 mm, so the difference between the three waveforms in the loading time of the specimen will be large. It is very large, which obviously has a large error for three-axis simultaneous loading. Therefore, a single loading rod mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com