Clamping device and experiment method for split Hopkinson torsion bar test piece

A clamping device and a separate technology, which is applied in the field of clamping devices for separate Hopkinson tie rod specimens, can solve the problems of difficult success in dynamic tensile experiments, inconvenient installation and disassembly, and poor versatility of connectors, etc. problems, to avoid difficult thread processing, strong versatility, and save test operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

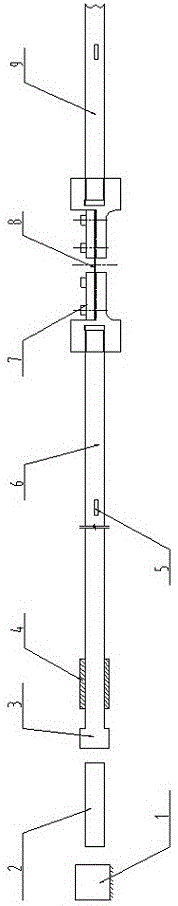

[0036] The Hopkinson tie rod system mainly consists of three parts: the support part, the main part of the tie rod and the data acquisition part. Among them, the bracket part is mainly used to support and fix the tie rod part and ensure the level of the tie rod. The main part of the tie rod consists of a buffer absorber, a single wave transmission rod, a loading joint, an impact tube (commonly known as a bullet), a barrel, an incident rod, a transmission rod and corresponding air pressure devices. The data acquisition system is composed of strain gauges pasted on the pole, Wheatstone bridge (strain gauge junction bridge box), ultra-dynamic strain gauges and high-speed acquisition system. Split Hopkinson tie rods consist of an impingement rod, an incident rod, a transmission rod and an energy absorber with the same material properties and outer diameter. When the impact rod collides with the incident rod coaxially, an approximate compression square wave is generated in the inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com