Pressure online detection auxiliary device and detection method thereof

A technology for auxiliary devices and detection methods, applied to measuring devices, measuring fluid pressure, instruments, etc., can solve problems such as product failure, production stoppage, pressure leakage, etc., and achieve the effects of low manufacturing cost, compact structure, and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

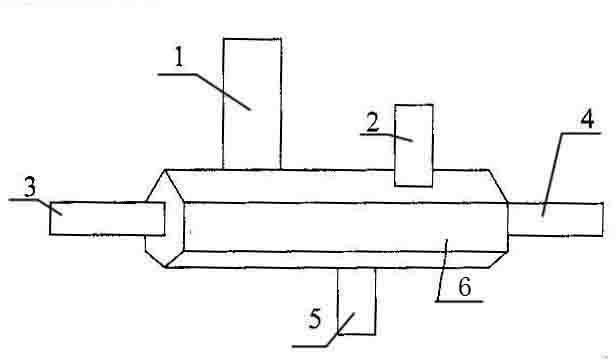

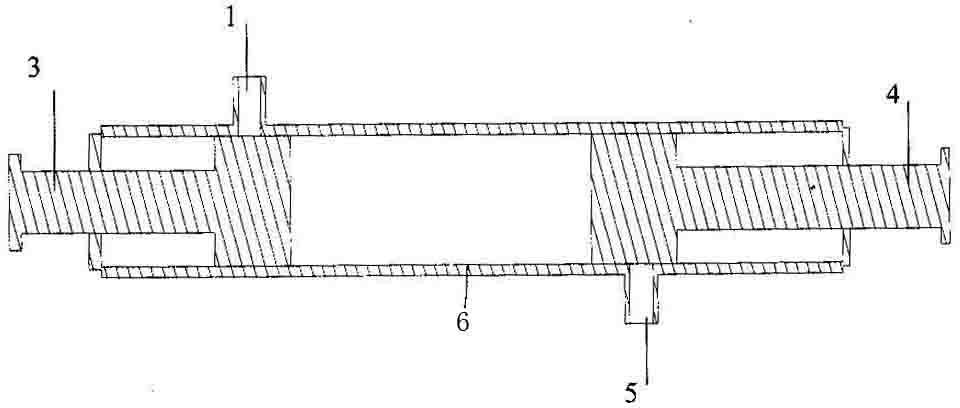

[0014] An auxiliary device for online pressure detection, including a pipeline detection cavity 6, which is a hexagonal prism outside and a hollow cylindrical cavity inside, and is respectively installed on the two bottom surfaces of the hexagonal prism outside the pipeline detection cavity The control knob I3 and the control knob II4 are respectively provided with a calibration port 1 , a pressure gauge direction interface 2 and a pipeline direction interface 5 on three adjacent sides of the hexagonal prism outside the pipeline detection cavity 6 .

[0015] The control knob I3 and control knob II4 are in the shape of a pull rod, one end of the pull rod is located inside the pipeline detection cavity 6, the end surface is a cylinder with the same inner diameter as the pipeline detection cavity 6, and the other end of the pull rod is located in the pipeline detection cavity Externally, the end faces are hexagonal.

[0016] The auxiliary device for on-line pressure detection wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com