Low-temperature submerged-arc automatic welding method for Q370qE steel

A technology of submerged arc automatic welding and low temperature welding, which is applied in welding equipment, welding accessories, arc welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

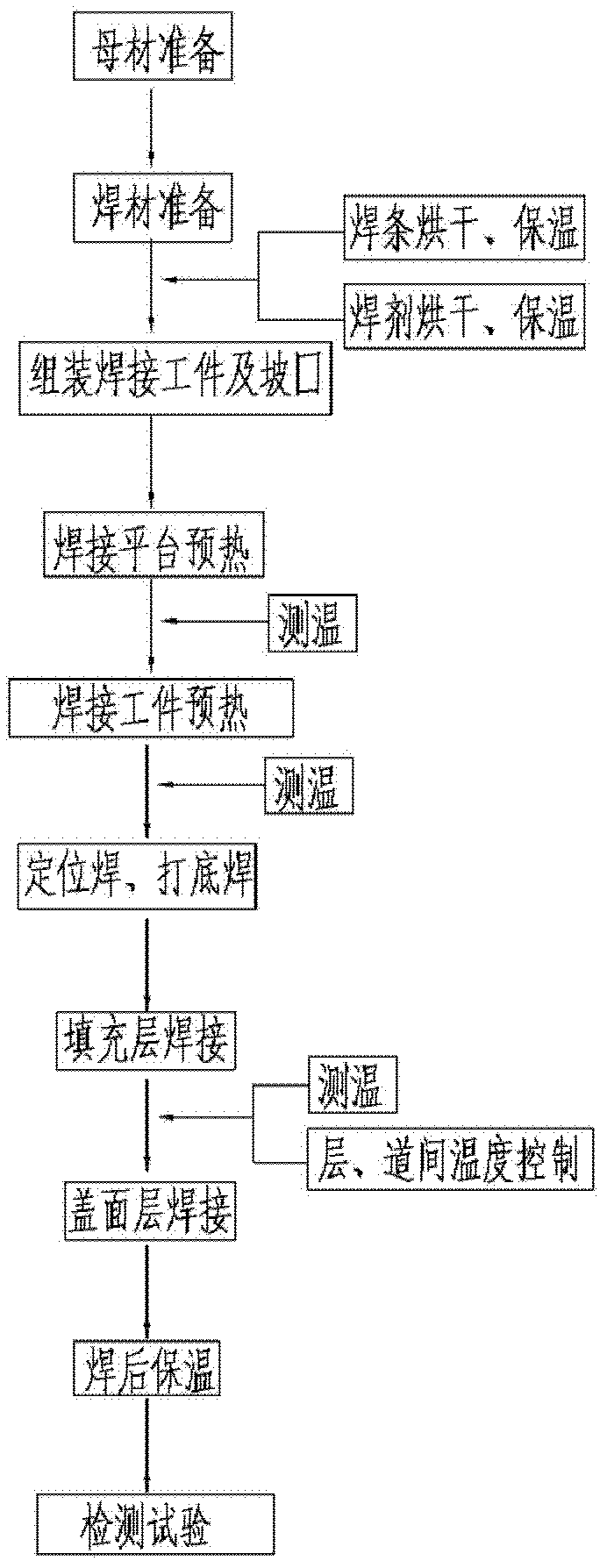

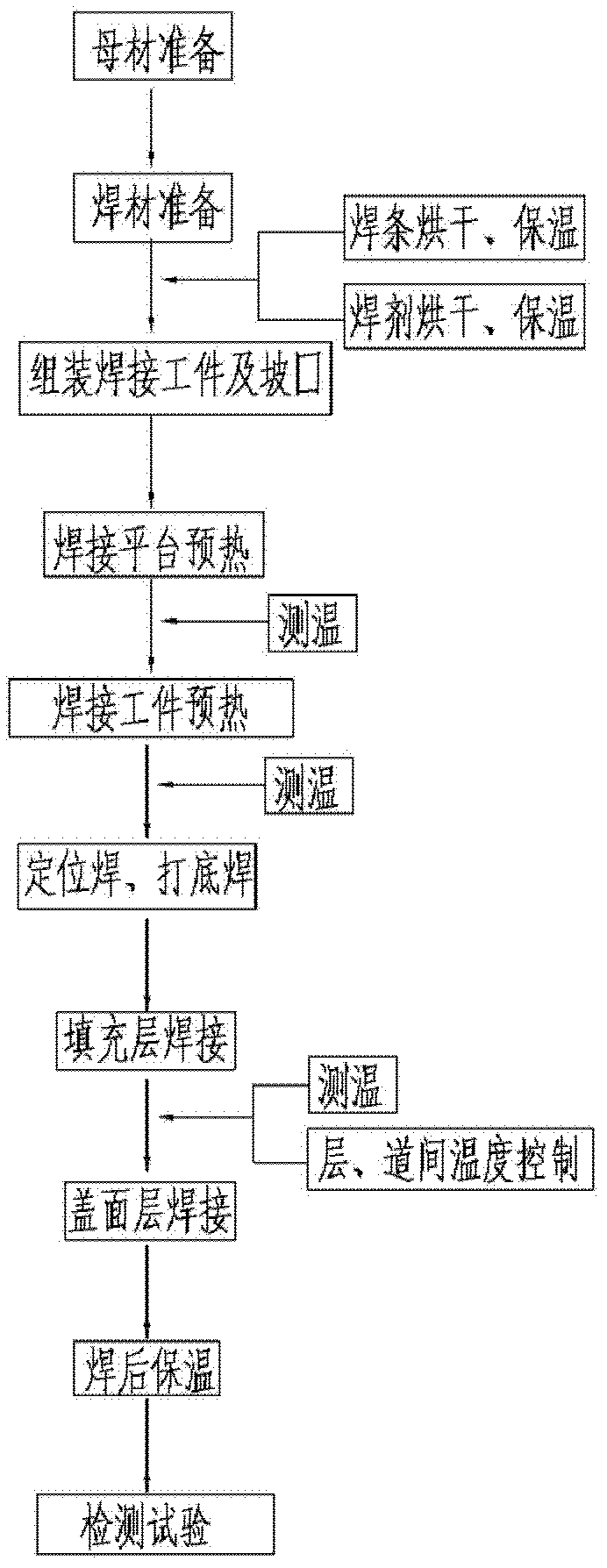

Method used

Image

Examples

Embodiment example 1

[0022] Under the working environment with a temperature of 0°C, automatic submerged arc welding of Q370qE steel is carried out.

[0023] Precisely cut the groove of the welding workpiece with flame, the depth of the groove of the welding workpiece is 14mm, assemble the welding workpiece to form the groove to be welded; dry the welding material according to the requirements, the drying temperature is 300 ° C, the drying time is 2 hours, and the incubator The storage temperature is 100°C; dehumidify and preheat the welding platform, the preheating temperature is 100°C; preheat the welding workpiece with a baking gun, the preheating temperature is 80°C, the preheating range is 100mm on both sides of the groove, using E5015 (diameter 4.0mm) welding rod for positioning welding, using solid core welding wire ER50-3 (diameter 1.2mm), argon-rich mixed gas shielded welding, for bottom welding; using solid core welding wire H10Mn2 (diameter 5.0mm) with flux SJ101 for burying Arc automat...

Embodiment example 2

[0027] The submerged arc automatic welding of Q370qE steel is carried out under the working environment with a temperature of -15°C.

[0028] Precisely cut the groove of the welding workpiece with flame, the depth of the welding groove is 36mm, assemble the welding workpiece to form the groove to be welded; dry the welding material according to the requirements, the drying temperature is 350°C, the drying time is 2 hours, and the storage temperature is 150°C ;Dehumidify and preheat the welding platform, the preheating temperature is 120°C; evenly spread asbestos on the welding platform, that is, the bottom side of the welding workpiece groove; preheat the welding workpiece with a baking gun, the preheating temperature is 120°C, and the preheating range is Groove and both sides 150mm, use E5015 (diameter 4.0mm) electrode for tack welding, use solid core wire ER50-3 (diameter 1.2mm), use argon-rich mixed gas shielded welding for bottom welding, use solid core wire H10Mn2 (diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com