Method for accurately controlling content of stearic acid in soybean oil by adopting mixed filler

A technology of mixing fillers and soybean oil, which is applied in the direction of fat oil/fat refining and fat production, which can solve the problems of inability to accurately control stearic acid content and high-quality fat emulsion preparations, and achieve the effect of prolonging the refining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

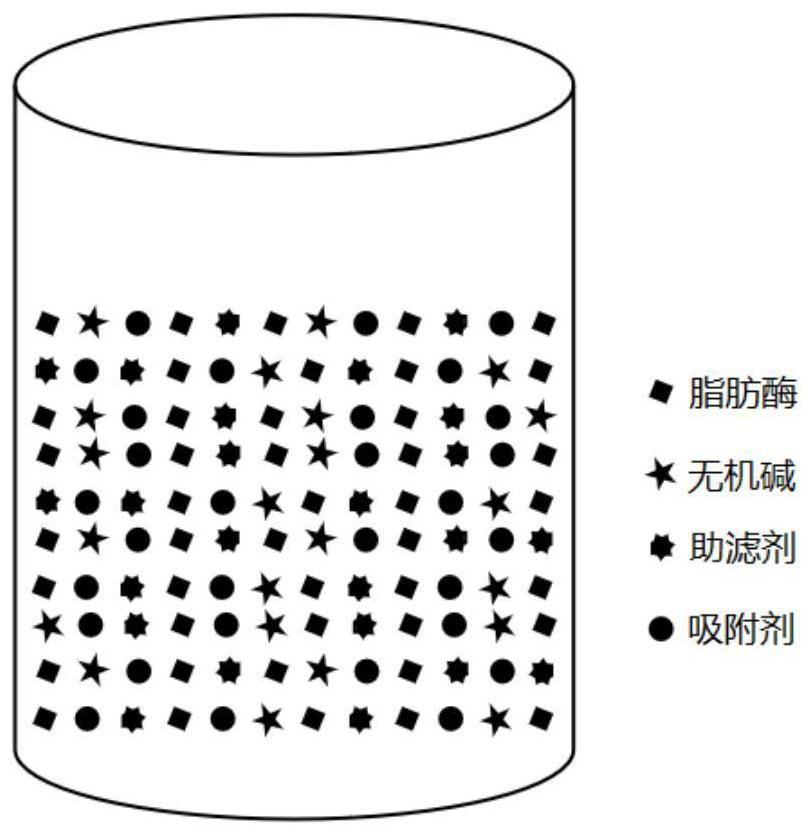

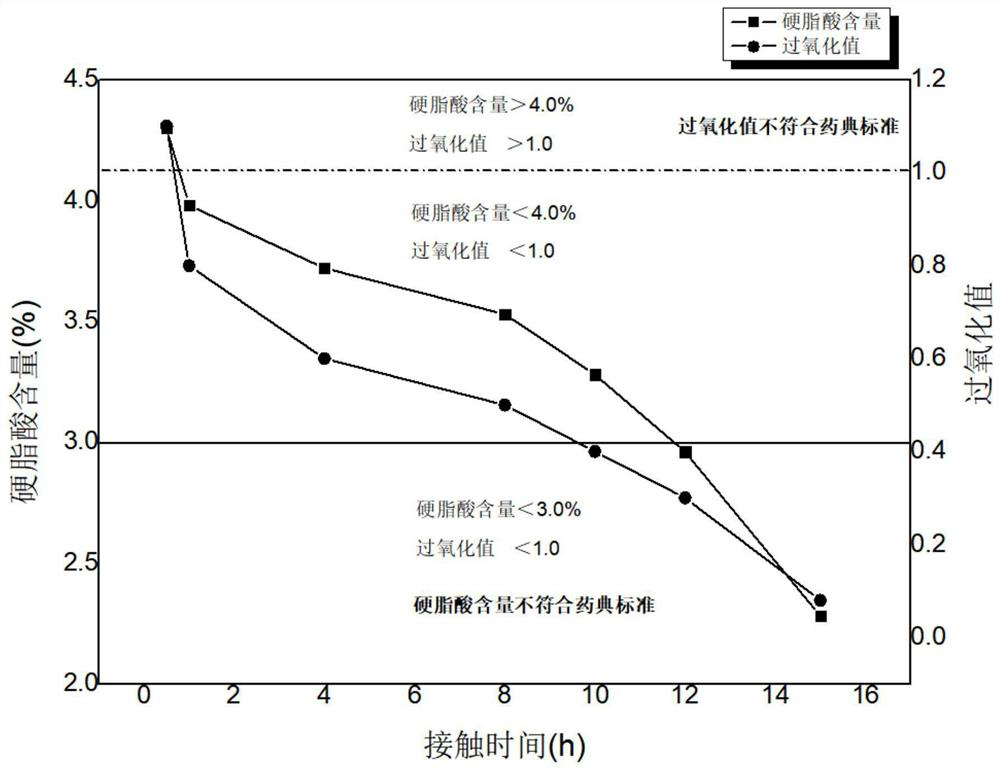

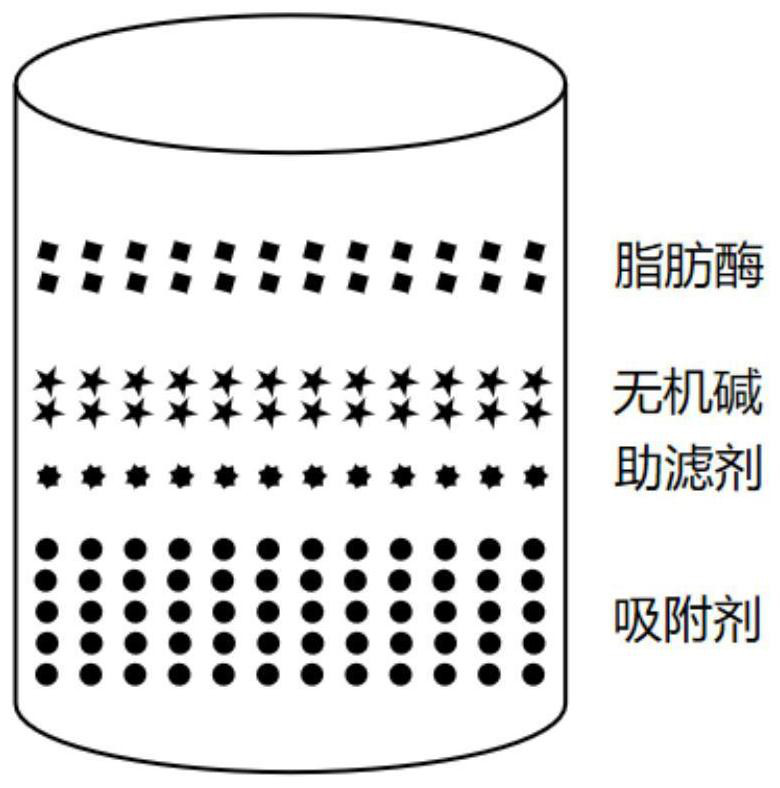

Method used

Image

Examples

Embodiment 1

[0045] 1 g of Sn-1,3-position specific lipase 435 lipase, 1 g of sodium hydroxide, 10 g of diatomaceous earth, and 10 g of alumina were weighed, and then added to the chromatography column after physical mixing. Take 1kg of edible soybean oil and carry out the above-mentioned mixed packing column chromatography column operation, the column temperature is controlled at 50±2°C, the pressure is controlled at 0.04±0.02mPa, and the column passing time is 10h. The acid value, methoxyaniline value, peroxide value and stearic acid content of edible soybean oil and post-column refined soybean oil were detected. The measurement results are shown in Table 1 (wherein, the acid value, peroxide value and methoxyaniline value were measured and calculated according to the method shown in the Pharmacopoeia).

[0046] Table 1 embodiment 1 edible soybean oil before and after refining key index measurement results

[0047]

[0048]

Embodiment 2

[0050] 10 g of Sn-1,3-position-specific lipase Lipase lipase, 10 g of sodium hydroxide, 50 g of diatomaceous earth, and 50 g of silica gel were weighed, and then added to a chromatography column after physical mixing. Take 1 kg of edible soybean oil, and carry out the above-mentioned mixed packing column chromatography column operation. The acid value, methoxyaniline value, peroxide value and stearic acid content of edible soybean oil and post-column refined soybean oil were detected. The measurement results are shown in Table 2 (wherein, the acid value, peroxide value and methoxyaniline value were measured and calculated according to the method shown in the Pharmacopoeia).

[0051] Table 2 embodiment 2 edible soybean oil before and after refining key index measurement results

[0052]

Embodiment 3

[0054] 100 g of Sn-1,3-specific lipase RMIM lipase, 100 g of calcium hydroxide, 50 g of bentonite, and 750 g of white clay were weighed, and then added to a chromatography column after thorough physical mixing. Take 5kg of edible soybean oil and pass it through a mixed packing chromatography column. The acid value, methoxyaniline value, peroxide value and stearic acid content of edible soybean oil and post-column refined soybean oil were detected. The measurement results are shown in Table 3 (wherein, the acid value, peroxide value and methoxyaniline value were measured and calculated according to the method shown in the Pharmacopoeia).

[0055] Table 3 embodiment 3 edible soybean oil before and after refining key index measurement results

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com